Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Millennial Four-Point Probe Tester Provides Efficient Industrial Measurement Technology

Date : 7 November 2023Views : 780

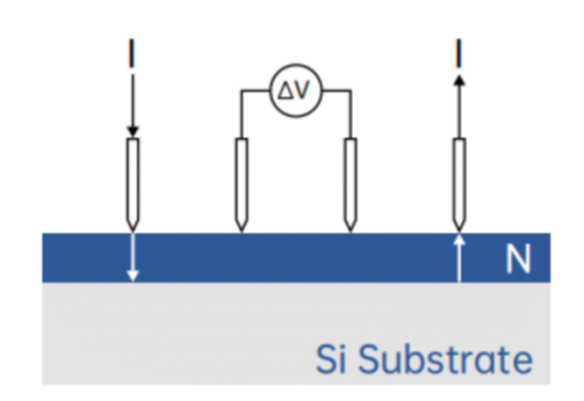

In the industrial production process of solar cells, traditional four-probe measurement technology often causes problems such as deviations in measurement data and damage to the integrity of solar cells after measurement. In order to help solar cell manufacturers easily deal with these problems encountered , Millennial Solar relies on its professional and unique technical understanding in the photovoltaic testing industry to produce Four-Point Probe Tester, which can realize fully automatic multi-point scanning measurement of solar cells after depositing ITO films. It greatly improves the quality inspection efficiency of solar cells in industrial production.

![]()

Four-Point Probe Tester

E-mail: market@millennialsolar.cn

The fully automatic multi-point scanning of Four-Point Probe Tester can efficiently and accurately measure samples up to 230mm, and obtain sheet resistance/resistivity distribution information at different sample locations based on the selection of multiple preset plans. In order to ensure Four-Point Probe Tester has high mechanical accuracy and long service life, the tester's probe head draws on the manufacturing process of mechanical clock movements and uses ruby bearings to guide the tungsten carbide probe.

●Ultra-high measurement range, measuring 0.1MΩ~100MΩ sheet resistance

●High-precision measurement, dynamic repetition rate can reach 0.2%

●Fully automatic multi-point scanning, multiple preset schemes can also be customized and adjusted

●Rapid material characterization and automatic calculation of correction factors

![]()

Solve the Problems Encountered by Traditional Four-probe Measurement Technology

In order to solve measurements in a variety of situations, Millennial Solar provides a wide range of probe types, which can be applied and optimized for characterization measurements of different sample surfaces, and can be used for almost any conductive film and ion implantation layer . Four-Point Probe Tester can ensure the integrity of samples and achieve non-destructive testing during the industrial production process.

In the large-scale industrial production process of photovoltaic cells, non-contact eddy current measurement is very limited in the quality inspection of solar cells. Non-contact eddy current measurement combines the thin layer resistivity of the substrate with the resistivity of the surface layer. Such measurement will lead to greater repeatability of measurement results when measuring a large number of solar cells, resulting in uncertainty in the solar cells.

The Four-Point Probe Tester produced by Millennial Solar can greatly ensure measurement certainty and reduce repeatability in the mass production of solar cells. The probe head can apply a spring-loaded function during measurement, so that when the sample rises to the probe head, the probe head compresses according to the surface of the sample being measured, thereby generating a constant contact force and ensuring the integrity of the sample. This is the most essential difference between Millennial Four-Point Probe Tester's contact measurement and non-contact eddy current measurement.

Four-Point Probe Tester can achieve fast and accurate measurement of samples, and can help solar cell manufacturers calculate the resistivity and sheet resistance of solar cells after depositing ITO films during the industrial production of solar cells. In the future, Millennial Solar will continue to be committed to developing various high-quality testing equipment to help customers produce solar cells efficiently, flexibly and quickly!