Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

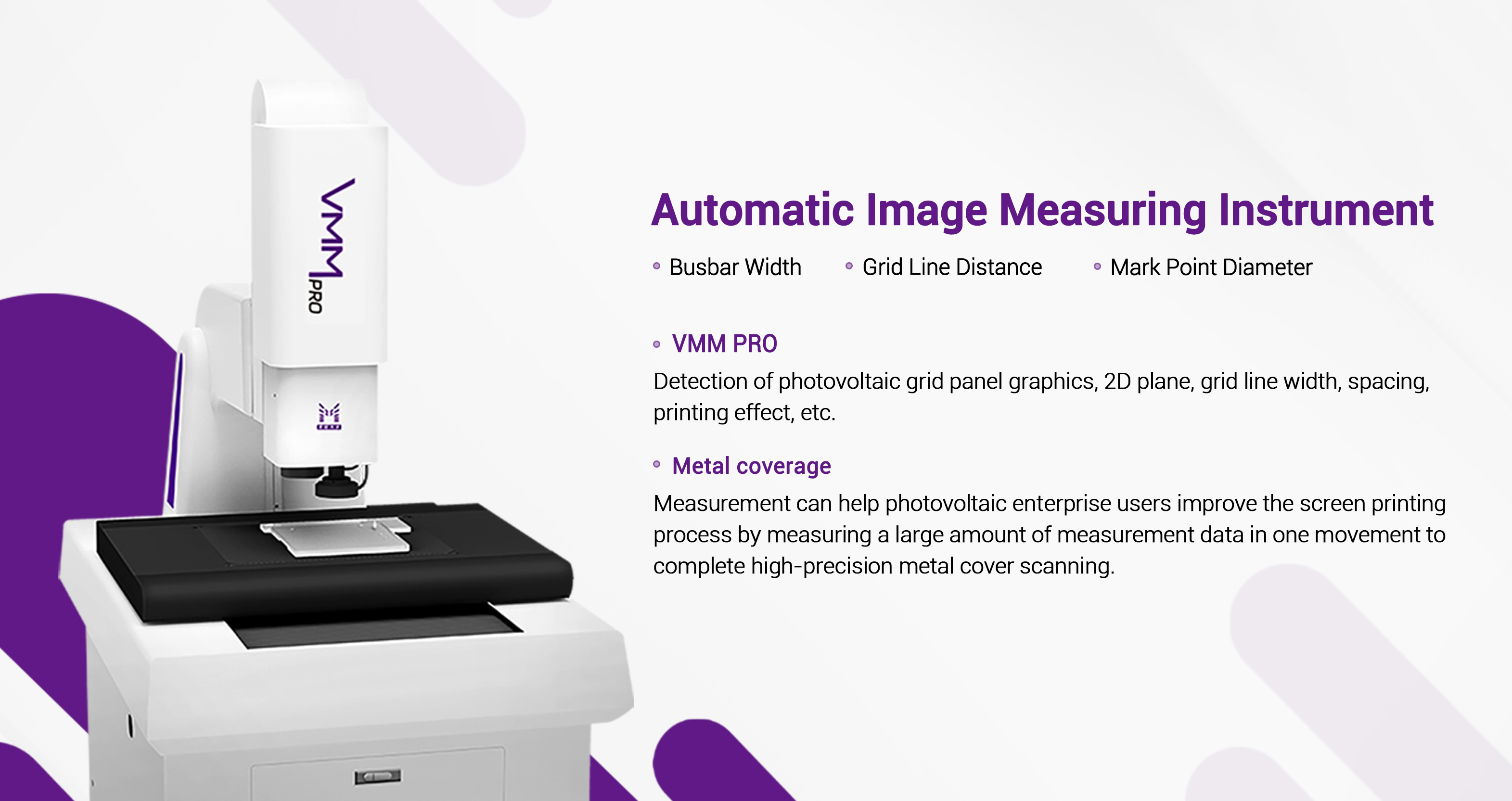

Quality and Efficiency? All You Need Is Automatic Image Measuring Instrument

Date : 14 August 2023Views : 1455

With the development of photovoltaic technology, cell manufacturers have higher and higher requirements for the quality of photovoltaic cell parts and the accuracy of measuring instruments. In order to adapt to the pace of development of the times, "Millennial Solar" according to customer needs, developed a fast, two-dimensional, high-precision measuring instrument——Automatic Image Measuring Instrument, which is used to measure photovoltaic cells such as TOPCon, HJT, perovskite and PERC, so as to help photovoltaic enterprise users improve the screen printing process in the cell production process!

![]()

High-quality Cells Are Not Far Away From Us

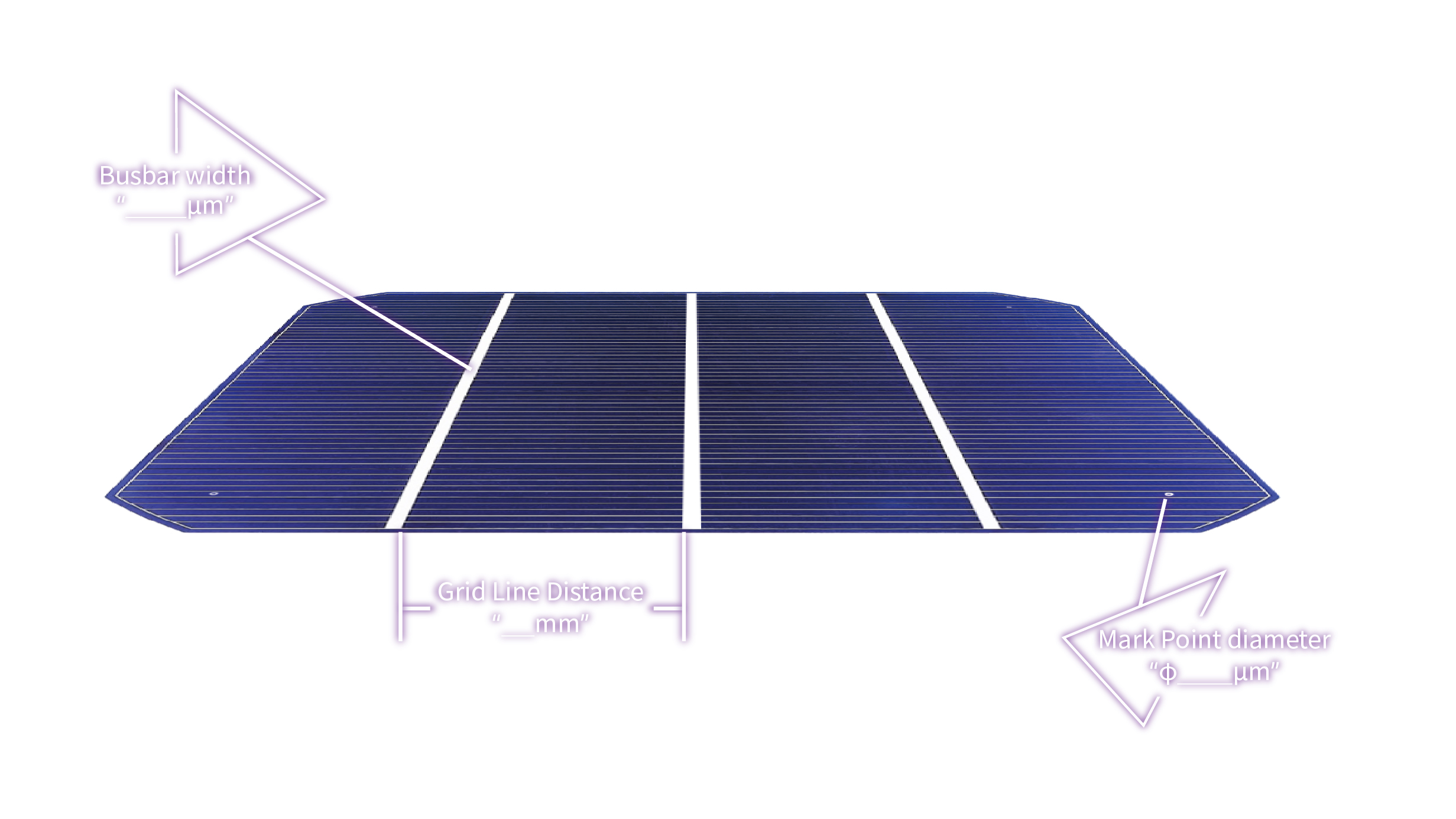

Millennial Automatic Image Measuring Instrument is equipped with a measurement system based on high resolution, which can be used to detect the pattern, 2D plane, and grid line width, spacing, printing effect and so on of solar cells so as to produce high-quality grid line electrodes to achieve the purpose of reducing the shading area, improving the battery JSC, and improving the efficiency of solar cells.

![]()

Excellent Optical Technology

Millennial Automatic Image Measuring Instrument uses an advanced optical system with 2 million high-definition pixels, equipped with automatic zoom lens and auxiliary lens, which can reflect 25-345 times video magnification on the computer display.

Millennial Automatic Image Measuring Instrument has the feature of automatically identifying the edge of the solar cell. The LED light source used can automatically adjust to the appropriate light source according to the lens magnification to improve the use efficiency. Thereby reducing errors between operators and consistency errors between instruments.

![]()

Accurate and Fast Focusing Function

Fast and accurate focusing is the key step to ensure the clarity of the measured image. Millennial Automatic Image Measuring Instrument can focus on the grid lines of photovoltaic cells in the fastest 1S, and the focusing repeatability can reach 0.002mm~0.003mm, and Introduced sub Pixel measurement function.

Subpixel is the smallest unit of the imaging surface of an area array camera, and the distance between pixel centers ranges from several to tens of microns. It can maximize the use of image information to improve resolution, and the sub-pixel measurement function can help beginners better observe the entire sample in real time, realize rapid product positioning, accurate measurement, and improve measurement efficiency.

![]()

Exclusive Metal Coverage Measurement

VMM PRO metal coverage refers to the area ratio of grid lines covering the entire photovoltaic cell.

Millennial Automatic Image Measuring Instrument can calculate a large amount of measurement data by moving the photovoltaic cell once, so as to complete high-precision cover scanning, and automatically identify the grid line area in the system software according to the scanning information, finally, the identified gridline area is calculated and divided by the total substrate area to obtain the metal coverage.

E-mail: market@millennialsolar.cn

The VMM PRO metal coverage function of Millennial Automatic Image Measuring Instrument can provide cell manufacturers with comprehensive measurement data collection and analysis services, reduce production costs, improve production speed and product quality, and help customers produce high-quality photovoltaic cells. In the future, "Millennial Solar" will join hands with you to promote the development of the photovoltaic industry!