Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Indispensable Equipment for HF Test: Humidity-freeze Test Chamber

Date : 16 August 2023Views : 875

In order to enable photovoltaic modules to meet the design and quality standards required for long-term use, since 1993, IEC 61215 has been an indicator of the quality of photovoltaic modules and has been continuously updated. This is one of the most common standards for photovoltaic modules. Among them, the Humidity-freeze Test is a test method for evaluating the durability performance of photovoltaic modules. Millennial Temperature and Humidity-freeze Test Chamber is an essential testing equipment for the solar industry.

![]()

What is humidity-freeze test?

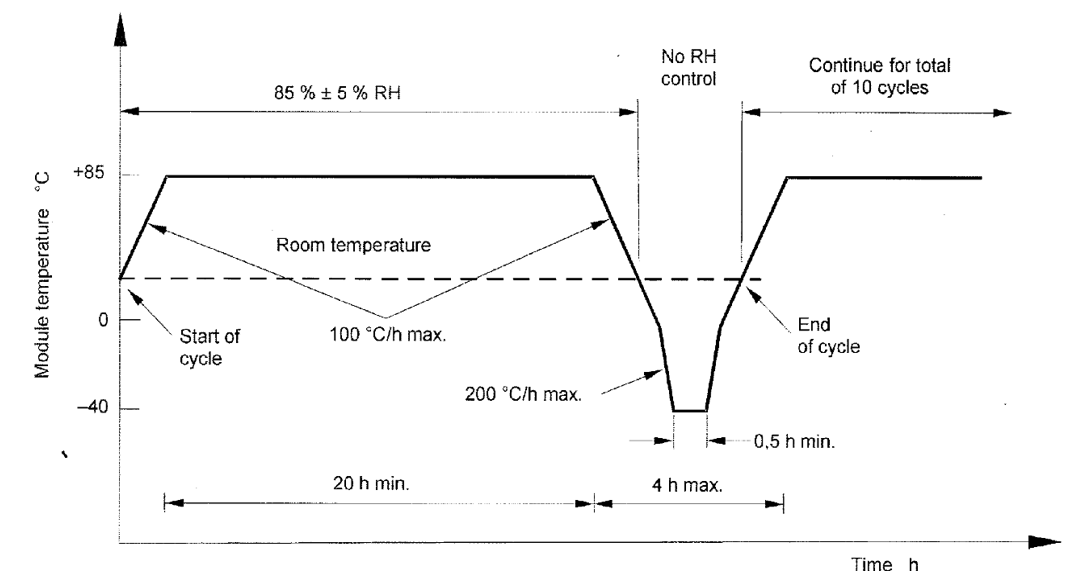

Humidity-freeze Test means that the photovoltaic module cycles between a temperature of 85°C (85% relative humidity) and -40°C, and monitors the continuity of the circuit. As outlined in the figure below, the PV modules were subjected to 10 complete cycles in a closed climate chamber. The purpose of the test is to determine the module's ability to withstand moisture penetration. By simulating the fatigue and aging process of photovoltaic modules under different climatic conditions, it is possible to detect whether the modules can maintain efficient and stable performance during long-term use.

Combine temperature changes and humidity to simulate the effects of frost

![]()

Millennial Temperature and Humidity-freeze Test Chamber

Introduction:

During the application process of solar modules, they will withstand various severe weather tests. Among them, the ability of the module to withstand high temperature and high humidity and the subsequent low temperature, and the ability to withstand long-term moisture penetration need to be evaluated. Humidity-freeze environmental simulation test, in order to verify and evaluate the reliability of components or materials, and through thermal fatigue induced failure mode, early identification of manufacturing defects.

Fulfill the standard:

IEC61215-MQT12; IEC61730-MST52

Features:

● Adopt intelligent energy-saving control method, according to the temperature demand in the box, PID controls the solenoid valve switch to output cooling capacity or PID controls the heating wire

● Equipped with an evaporating pressure regulating valve to precisely control the temperature of the evaporator and prevent the evaporator from freezing in a high humidity environment

● Equipped with independent return and exhaust temperature control loops

● A series of energy saving and emission reduction processes such as oxygen-free copper tube gas shielded welding

![]()

Millennial Temperature and Humidity-freeze Test Chamber is used with Current Continuity Monitoring System

E-mail: market@millennialsolar.cn

The Millennial Current Continuity Monitoring System is specially developed for the 11 Thermal Cycling Test experimental clauses and 12 Humidity-freeze Test clauses in the IEC61215 standard. It mainly includes providing stable DC, current recording, temperature recording and temperature control functions, controlling the opening of DC power supply through temperature, and long-term real-time monitoring of multi-channel current and multi-channel temperature. Used in conjunction with the high and low temperature humidity and freezing test chamber, it can monitor the continuity of the internal circuits of multiple components. Judging the fatigue resistance of materials, the rationality of lamination process, and the stability of welding quality of solar cell modules in high and low temperature alternating environments.

Through the Humidity-freeze Test of photovoltaic modules, it is possible to detect whether there are problems such as thermal stress or humidity stress in the modules, so as to better judge the durability and long-term stability of the modules. This test is also one of the necessary tests before the application of solar photovoltaic modules, which can provide important references for the design, manufacture, and quality control of photovoltaic modules. The components tested by the Millennial Temperature and Humidity-freeze Test Chamber can provide you with long-term and stable renewable energy.