Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Mechanical Performance Test of Modules -Indispensable Millennial Mechanical Load Tester

Date : 22 September 2023Views : 1020

As a product with a service life of 25-30 years, photovoltaic modules need to have high reliability to provide power generation guarantee for the entire life cycle of the photovoltaic system. For photovoltaic modules, in addition to environmental aging requirements, people also attach great importance to the mechanical properties of the modules. According to the requirements of IEC61215, the mechanical load test includes static mechanical load test and dynamic mechanical load test. Static Mechanical Load Tester and Dynamic Mechanical Load Tester from "Millennial Solar" solve your troubles in load test of photovoltaic modules.

![]()

load test

Whether it is static load test or dynamic load test, the test methods have their unique characteristics, and the two can complement each other, but cannot be replaced.

Static load test:

IEC 61215 and IEC 61646 standards give the test method of mechanical load test of photovoltaic modules, static mechanical load test, the purpose is to test the ability of modules to withstand static load. After installing the modules on the bracket according to the specified method, gradually add the load to 2400Pa on the front and back surfaces of the modules to make it evenly distributed. Keep the load for 1 hour, so it is 1 cycle, and the whole test should be carried out 3 times. During the whole test, the continuity of the internal circuit of the modules is monitored. After the test, check whether there is intermittent disconnection or serious appearance defects during the test, and conduct the maximum output power test and insulation resistance test under standard test conditions.

The determination of the minimum design load of the modules depends on the module structure, applicable standards, and the installation site and climate, and may require a higher sample sampling rate.

Dynamic load test:

IEC 62782 provides a relatively systematic test method for the dynamic mechanical load test of photovoltaic modules: place the modules in the dynamic load system, connect the positive and negative poles of the modules with the positive and negative poles of the DC source, and apply an appropriate current. Apply dynamic mechanical load to the modules, cycle 1000 times, complete 1~3 cycles per minute, the maximum pressure is ±1000Pa, and the holding time under the ultimate pressure is at least 7±3 seconds. During the test, the circuit continuity of the modules is monitored. Before and after the dynamic mechanical load is applied, a series of tests such as visual inspection, performance at NOCT, insulation test, twist test in IEC 61215 or IEC 61646 should be carried out to analyze the influence of dynamic mechanical load on the modules. In order to better simulate the actual test conditions, dynamic mechanical load testing is bound to be the direction of future development.

![]()

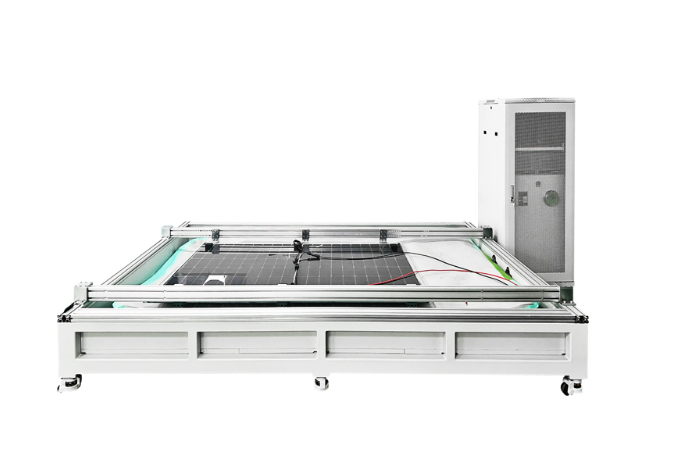

Millennial Static Mechanical Load Tester

E-mail: market@millennialsolar.cn

Introduction:

Static Mechanical Load Tester is designed and manufactured according to the mechanical load test conditions and methods in the corresponding standards of IEC61215-MQT16 and IEC61730-MST34. Static Mechanical Load Tester is a general-purpose testing platform for determining the ability of ground-use photovoltaic modules to withstand static loads such as wind, snow or ice.

Fulfill the standard:

IEC61215-MQT16;IEC61730-MST34

Features:

●The solution adopts modular design, and users can purchase and integrate components according to their needs;

●Equipped with a monitor, the current of the monitored components can be recorded in real time, the real-time curve, the current reduction can alarm, and the data can be exported;

●Deformation tester to test the deformation of photovoltaic modules;

![]()

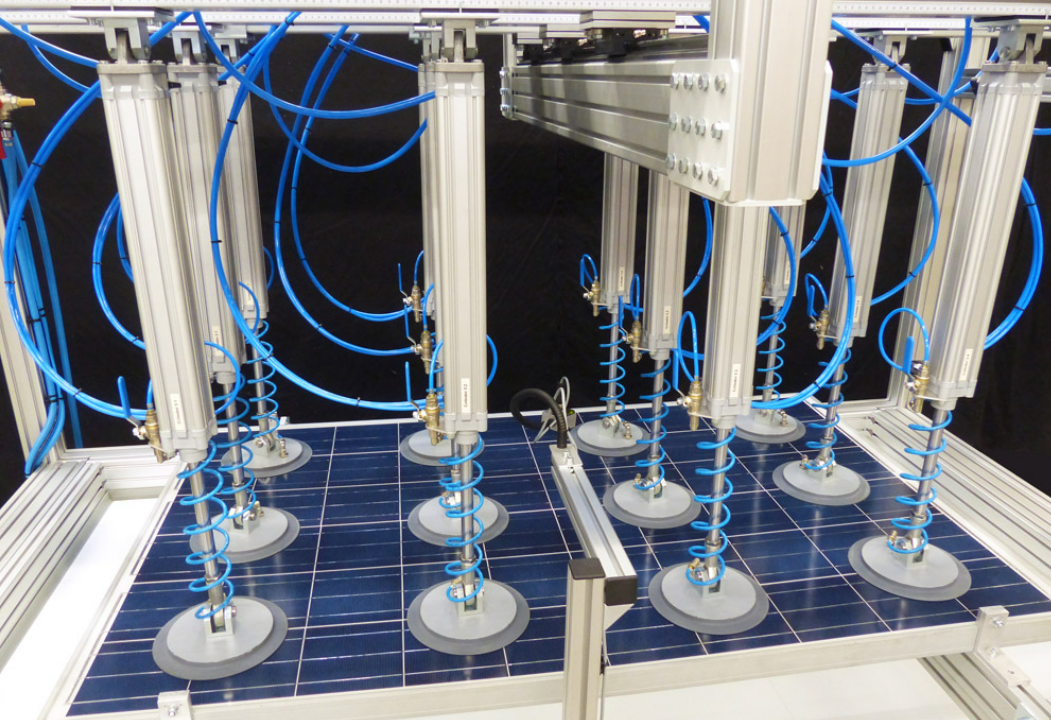

Millennial Dynamic Mechanical Load Tester

E-mail: market@millennialsolar.cn

Introduction:

Photovoltaic modules are under the pressure of heavy objects such as wind, snow, and ice during outdoor applications. If the strength of the modules does not meet the requirements, the modules will deform too much under the pressure of heavy objects, which will cause cell splits and edge sealing, etc. Undesirable consequences lead to a reduction in the power generation of the modules.Dynamic mechanical load test, in order to verify the reliability of the produced photovoltaic modules and ensure their ability to withstand different forces and weather conditions.

Fulfill the standard:

IEC61215-MQT16、 MQT20;IEC61730-MST34

Features:

80mm×160mm high-strength aluminum profile is used as the main frame of the equipment

All parts are processed by high-precision CNC; the surface treatment of aluminum parts is anodized

Cylinder and solenoid valve use SMC brand (or the same grade brand) to ensure its quality and service life

The power system adopts high-precision tension and pressure sensors to ensure the uniformity of the output of each cylinder

The output of the cylinder is controlled by a high-precision numerical control proportional valve, and the SMC brand (or the same grade brand) is selected to ensure the stability of the output of the cylinder

The deformation of photovoltaic modules is captured by non-contact infrared sensors to ensure high accuracy of data capture

Photovoltaic module load test is an important means to evaluate the performance of photovoltaic modules, and is of great significance to the power generation efficiency, performance and service life of photovoltaic modules. Time is the best touchstone. Only with solid and reliable quality can it stand the test of time. Together with "Millennial Solar", we will explore the answer to the future development of the photovoltaic industry.