Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

An Important Factor Affecting the Power of Photovoltaic Modules - Hot Spot Effect

Date : 27 September 2023Views : 865

Since solar cell modules are usually installed in wide areas and sunny areas, they will inevitably be blocked by various obstructions during long-term use. In view of the existence of these obstructions, shadows will be produced on the surface of the solar cells of the photovoltaic module, which will not only cause a decrease in the output power of the photovoltaic module, but may also cause hot spot effect. The solar simulator produced by Millennial Solar can meet the hot spot durability test in the IEC61215 standard test, helping photovoltaic module manufacturers to efficiently detect the power of photovoltaic modules after hot spots are generated, thereby enabling photovoltaic module manufacturers to carry out targeted solutions.

![]()

What is hot spot effect?

The hot spot effect of photovoltaic modules means that under certain conditions, the blocked or defective areas in the series branches of photovoltaic modules in power generation are used as loads, consuming the energy generated in other areas, resulting in local overheating.This phenomenon is called the "hot spot effect."

![]()

Causes of hot spot effect

There are many reasons for the hot spot effect in photovoltaic modules. When the solar cells themselves have defects, such as bubbles, delamination, internal connection failures, etc., the hot spot effect will occur.

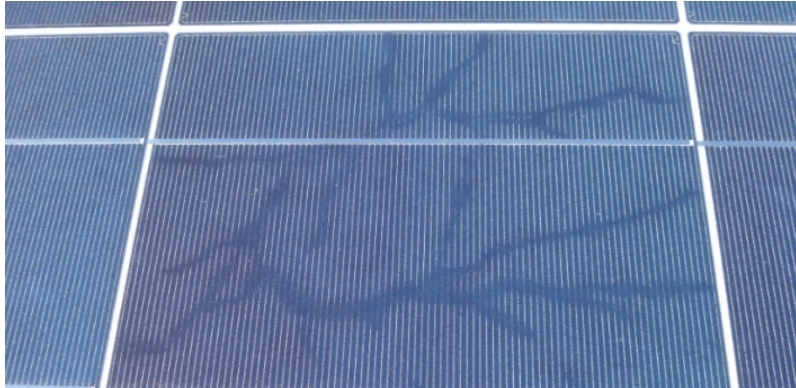

Severe cracks or fragments in photovoltaic modules will also cause hot spot effects. Excessive vibration, external impact, or uneven stress on the glass surface during installation may cause cracks in the cells. Cell cracks are also a defect of solar cells. For photovoltaic module access, the resistance of the cracked part increases, which can easily cause a hot spot effect.

When the surface of the photovoltaic module is stuck with stubborn stains or is blocked by debris or vegetation. The electronic transition activity of the blocked part of the solar cell is reduced, and the corresponding resistance increases, and the loss will also increase accordingly. The loss will be released in the form of temperature, and the temperature of the blocked part will increase, which will cause a hot spot effect.

![]()

Millennial Solar Simulator

E-mail: market@millennialsolar.cn

Millennial solar simulator uses metal halide lamps that can simulate the full sunlight spectrum to reproduce the destructive light waves that exist in different environments. It can provide testing and simulation in different environments for photovoltaic product development and quality assurance.

It can also meet the stability test specified in the IEC61215 standard test for exposure, maximum power point determination, and hot spot test terms. The spot area can reach 2800*2500mm, and the spectrum meets the BBA standard.

● Can realize local temperature control, the temperature control range is 60℃±10℃

● Irradiation area reaches 5200mm*4200mm

●Irradiance range can reach 700~1300w/m^-1

● The irradiation intensity of each light source or the overall irradiation intensity can be manually adjusted

● High spectrum matching, strong uniformity and stability of irradiation

Although photovoltaic module customers often pay attention to the phenomenon of shadows covering the cells when choosing solar module base stations, the hot spot effect caused by the shadow phenomenon is difficult to avoid, and photovoltaic module manufacturers can only avoid the hot spot effect to the greatest extent. The solar simulator owned by Millennial Solar can efficiently detect the hot spot effect in photovoltaic modules and provide targeted solutions according to the MQT09 clause in the IEC61215 photovoltaic module solution.