Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

An Important Process in the Production of Solar Cells - Screen Printing

Date : 27 September 2023Views : 1020

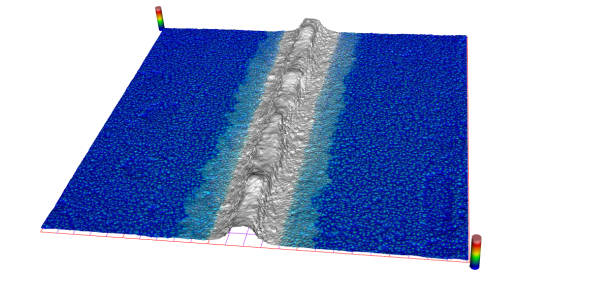

In the manufacturing process of solar cells, in order to prepare solar cell contact electrodes, it is necessary to print metal paste on silicon wafers by screen printing technology. After the sintering process, front and back electrodes are formed on the surface of the solar cell, through which the current of the cell is collected and transmitted.Millennial 3D microscope can detect the number of grid lines and pyramids on the photovoltaic cell through the system software, helping users to master the quality of solar cell cleaning, texturing, and screen printing processes.

![]()

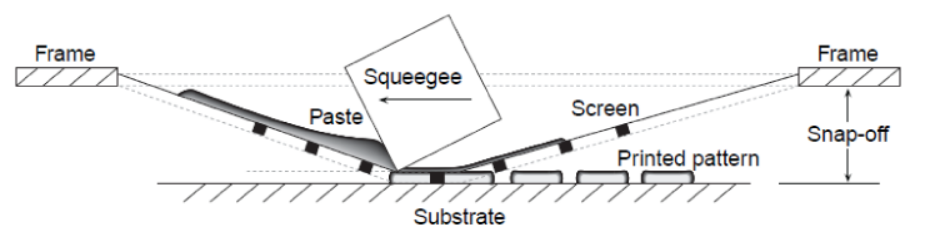

Screen Printing Process

The process steps of screen printing are: printing the back electrode with silver paste→drying→printing the back field with aluminum paste→drying→printing the front grid with silver paste→drying. The printed pattern is required to be complete, clear, uniform and symmetrical.

When performing screen printing, the printing pattern should be designed first and made into a screen. The meshes that need to form the graphics part on the screen are transparent, and the non-graphics parts are closed. When printing, spread the slurry on the screen, the blade of the scraper is close to the screen surface of the screen to scrape the slurry horizontally, and apply appropriate pressure to make the screen contact with the silicon wafer, and the slurry is squeezed out of the mesh and then adhered on a silicon wafer. Because there is a gap between the stencil and the silicon wafer, the stencil will use its own tension to contact the silicon wafer for an instant and then immediately break away from the silicon wafer and rebound. Graphically defined areas of the board are adhered to the slurry.

Using screen printing to make solar cell electrodes has the characteristics of low production cost and high production capacity, and is currently a widely used method in large-scale production. In addition to screen printing, there are other methods to make electrodes, such as groove buried grid method, inkjet printing method, stencil printing method, etc., but most of them have not been applied to large-scale production because of high cost or immature technology.

![]()

Millennial 3D Microscope

E-mail: market@millennialsolar.cn

Millennial 3D Microscope is a high-speed confocal scanning microscope for accurate and reliable 3-dimensional (3D) measurements. Real-time confocal microscopy images are realized by fast optical scanning modules and signal processing algorithms.

Millennial 3D Microscope has high-definition confocal microscopy technology, precise high-resolution scanning technology, and solvent materials that are difficult to distinguish on the surface can also be presented. The Z-axis display resolution is as high as 1nm, which can accurately obtain tiny shapes.

Based on the principle of optical technology, combined with precise Z-direction scanning module and 3D modeling algorithm, etc., non-contact scanning is performed on the surface of the device and a 3D image of the surface is established. Quantitative detection of the number of pyramids in order to feedback the quality of photovoltaic cell cleaning, texturing, and screen printing processes.