Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

An Important Preparation Process for Depositing ITO Thin Films - PECVD Coating

Date : 17 October 2023Views : 865

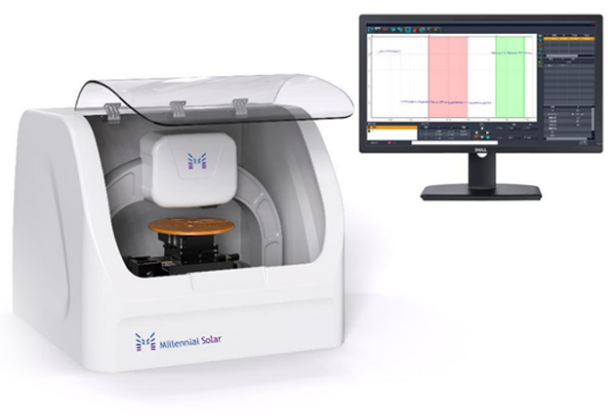

As a process in solar cell production, PECVD plays a key role in improving its performance. PECVD can deposit silicon nitride thin films on the surface of solar cells, thereby effectively improving the photoelectric conversion rate of solar cells. However, in order to clearly and objectively detect the ITO film of the solar cell after deposition and understand various parameters such as the film thickness and surface roughness, Stylus Profiler must be used for measurement. The Stylus Profiler produced by "Millennial Solar" can measure various parameter information such as surface roughness and warping stress of silicon nitride films in solar cells, and evaluate issues related to solar cell performance for photovoltaic enterprise users.

![]()

In-depth understanding of the basic principles of PECVD process

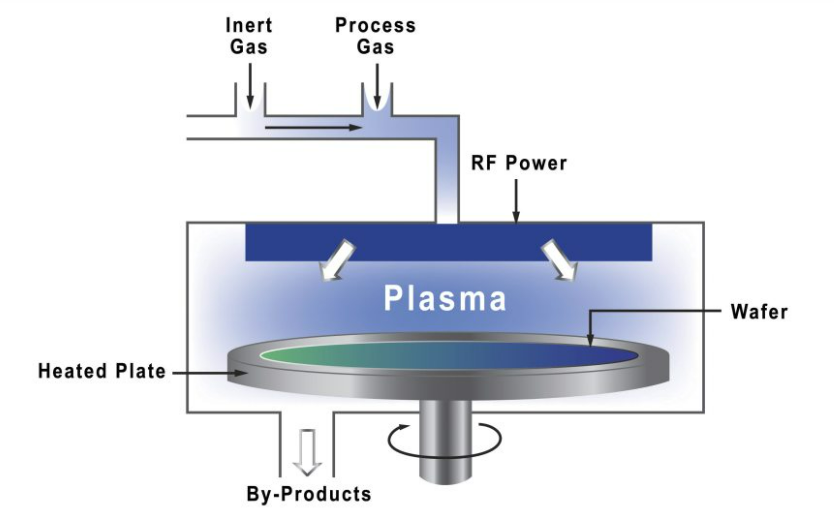

PECVD, also called plasma chemical vapor deposition, is a thin film growth technology that uses plasma to deposit at low temperatures.PECVD technology uses low-temperature plasma to generate glow discharge on the cathode of the process chamber under low pressure, and then uses the glow discharge to heat the sample to a predetermined temperature.Then an appropriate amount of process gas is introduced, and these gases are decomposed at high temperature through a series of chemical reactions and plasma reactions to generate the required compounds, and then the compounds are deposited on the surface of the solar cell or other substrate materials to form a thin film.

Basic principles of PECVD process

![]()

Process advantages of PECVD

Compared with traditional CVD, one of the main advantages of PECVD is that it can operate at lower temperatures, thereby reducing thermal stress on the substrate material, and is widely applicable to the manufacturing of solar cells. The PECVD plasma contains a large number of high-energy electrons, which can provide the activation energy required for the chemical vapor deposition process.The collision of electrons and gas phase molecules can promote the decomposition, combination, excitation and electrical processes of gas molecules, generating various highly active chemical groups, thereby significantly reducing the temperature range of CVD film deposition, making it possible to perform processes that originally required high temperatures. Thin film deposition is also possible at low temperatures.

![]()

Millennial Stylus Profiler

E-mail: market@millennialsolar.cn

Millennial Stylus Profiler is an advanced micro-nano measuring instrument that uses excellent instrument system construction and optimized measurement and data processing software to measure surface roughness, waviness, surface 2D/3D shape, warpage and stress. This enables reliable, efficient, and simple sample testing and completes perfect control from research and development to quality control.

●Equipped with 5 million pixel high-resolution color camera

●Step height repeatability 1nm

●Ultra-high straightness guide rail, reflecting the micro-morphology of the sample

●Sub-angstrom resolution, up to 0.01 angstrom in 13μm range

●High and low noise ratio and low linear error

As a key step that can directly improve the performance of solar cells through thin film deposition, the PECVD process has always been a process that major photovoltaic cell manufacturers focus on. Stylus Profiler produced by "Millennial Solar" relies on unique detection technology to provide targeted detection of silicon nitride films deposited on the surface of solar cells, helping photovoltaic cell manufacturers evaluate the performance of solar cells after film deposition, thereby achieving strong scientific proof !