Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

ITO Thin Film Deposition for Heterojunction Cells

Date : 27 October 2023Views : 850

Since heterojunction cells are different from traditional thermal diffusion crystalline silicon solar cells, after completing the injection of the emitter and BSF, the next step is to deposit ITO films on the front and back of the heterojunction cell. The ITO film can compensate for the low conductivity of heterojunction cells after injecting the emitter. The Four-Point Probe Tester produced by Millennial Solar can efficiently measure the resistivity and sheet resistance of heterojunction cells after depositing ITO films, thereby evaluating whether the performance of heterojunction cells meets industrial standards.

![]()

Characteristics of ITO film

The ITO film is an N-type oxide semiconductor - indium tin oxide. Because it uses tin and oxygen as donors, it can maintain stable conductivity and visible light transmittance at room temperature. Due to its high mechanical hardness and good chemical stability, it can become a commonly used thin film material for heterojunction solar cells.

![]()

Problems with the process of preparing ITO thin films at low sputtering voltage

Since the ITO film itself contains oxygen, when the magnetron sputtering method is used to deposit the ITO film, a large number of oxygen anions will be generated. The oxygen anions will bombard the surface of the deposited ITO film with a certain particle energy under the action of the electric field. The crystal structure and crystal state of the ITO film cause structural defects. The greater the sputtering voltage, the greater the energy of oxygen negative ions bombarding the surface of the film layer. Therefore, the probability of causing such structural defects will increase, and the more serious the crystal structure defects will be, which causes the resistivity of the ITO film to increase.

Under normal circumstances, the sputtering voltage when depositing ITO films by magnetron sputtering is around -400V. If a certain process method is used to reduce the sputtering voltage by more than 50%, it will not only improve the quality of the ITO film, but also reduce the sputtering voltage by more than 50%. It can also reduce the resistivity of ITO film, also reduces the preparation cost of depositing ITO films into heterojunction cells.

![]()

Methods to reduce structural defects of ITO films

In order to reduce the sputtering voltage of the ITO film, it can be achieved by reasonably increasing the magnetic field intensity of the sputtering cathode. Therefore, a special set of sputtering cathode structure and sputtering DC power supply can be used. At the same time, the RF power supply can be reasonably installed on the DC power supply, and the process research on reducing the sputtering voltage of ITO thin films can be carried out under different DC sputtering power and RF power. , thereby effectively controlling the sputtering voltage when depositing the ITO film, and achieving the purpose of reducing the resistivity of the ITO film.

![]()

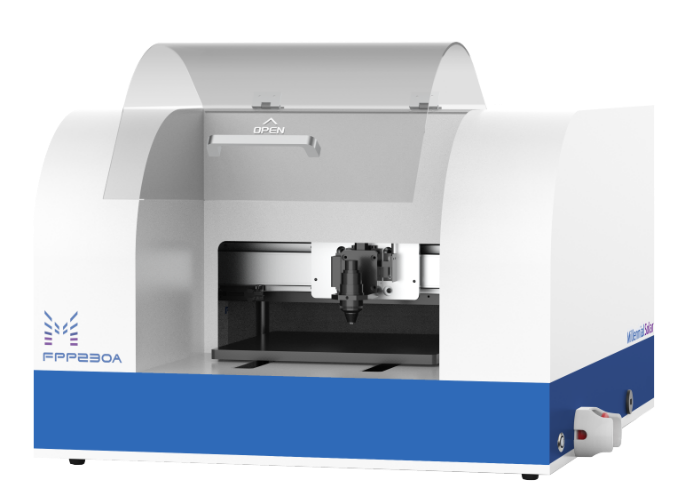

Four-Point Probe Tester

E-mail: market@millennialsolar.cn

Four-Point Probe Tester can quickly and automatically scan samples up to 230mm to obtain sheet resistance/resistivity distribution information at different locations of the sample. It can be widely used in photovoltaics, semiconductors, alloys, ceramics and many other fields.

● Ultra-high measurement range, measuring 0.1MΩ~100MΩ sheet resistance

● High-precision measurement, dynamic repetition rate can reach 0.2%

● Fully automatic multi-point scanning, multiple preset schemes can also be customized and adjusted

● Rapid material characterization and automatic calculation of correction factors

Since the low resistivity and high transmittance of ITO films can greatly improve the photoelectric conversion rate of heterojunction cells, thin film deposition for heterojunction cells is particularly important. The Four-Point Probe Tester produced by Millennial Solar can efficiently and quickly measure the performance of heterojunction cells after thin film deposition in large-scale industrial production of solar cells through fully automatic multi-point scanning, helping solar cell manufacturers to produce high-quality heterojunction solar cells!