Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Automated Measurements With Millennial 3D Microscope

Date : 8 November 2023Views : 990

With the rapid development of the photovoltaic industry, the quality requirements of solar cells are becoming higher and higher, among which the quality of the busbar and textured surface of solar cells is very critical. In order to determine whether the busbar and textured surface of solar cells meet industry quality standards, they need to be precisely inspected. 3D Microscope measures them efficiently and generates data and images based on the measurements in real time.

E-mail: market@millennialsolar.cn

![]()

Unique high-definition confocal microscopy technology

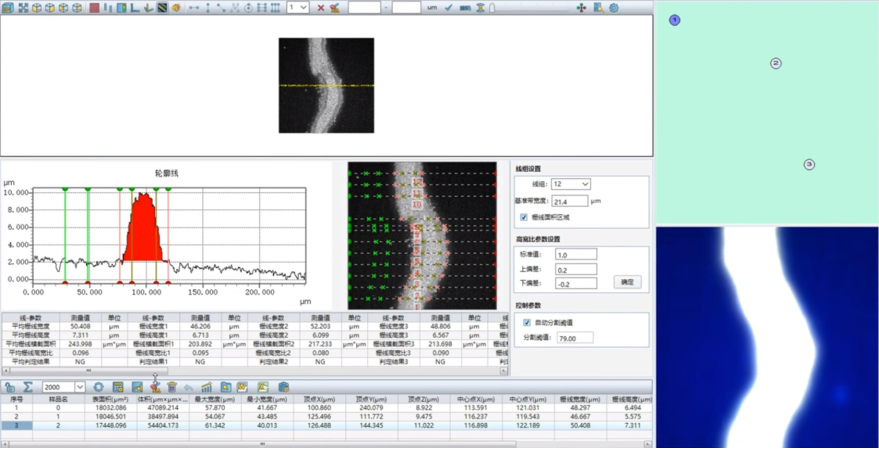

Millennial 3D Microscope is a high-speed confocal microscope that uses high-definition confocal microscopy technology to generate real-time 3D confocal microscopy images based on fast optical scanning modules and signal processing algorithms. The system software is used to quantitatively detect the height and width of the busbar of the photovoltaic cells and the number of pyramids on the textured surface to provide feedback on the quality of the solar cell cleaning, texturing and screen printing processes. It is an optical instrument that can perform quality inspection on the busbar and textured surface on the surface of photovoltaic cells.

![]()

Highly efficient automated measurement

Millennial 3D confocal microscope does not require personnel to be present during the measurement. You only need to preset multiple coordinate points on the sample to be measured, and automatically make OK/NG judgments based on the preset coordinate points to start automated measurement.

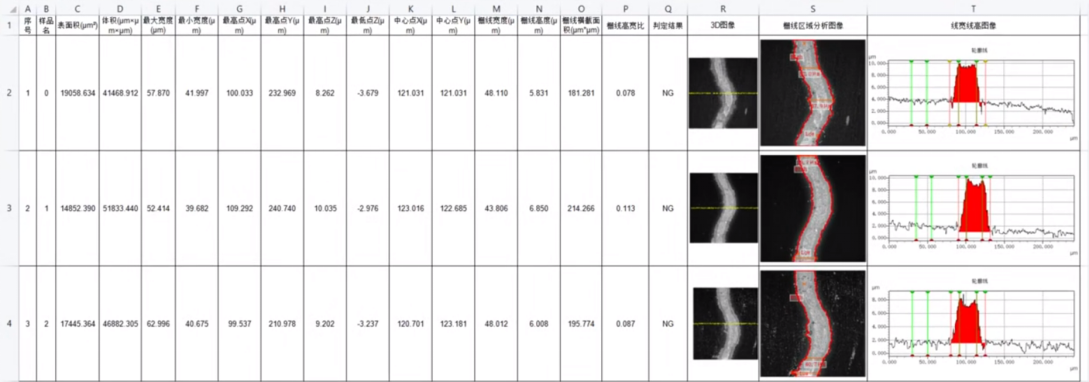

After specifying the XY coordinate position of the test point, the unique microscope magnification of Millennial 3D confocal microscope is used to automatically position and focus, thereby starting to automatically measure the busbar area, line height and line width analysis of the solar cell. After the analysis is completed, the measurement of the next designated test point will be automatically started, and the above operation will be repeated until all preset coordinate points are measured.

After the test is completed, a data report is automatically generated. Based on the data report information, the specific information of each preset coordinate point in the solar cell can be clearly understood. Such as the height, width, aspect ratio of the busbar, the average height of the textured surface of the pyramid, the number of pyramids in the measured area, and the width and height of any pyramid, etc.

Automated measurement simplifies the measurement operation steps, allowing users to obtain the measurement data or images they want more quickly. The automated measurement technology possessed by Millennial 3D confocal microscope not only realizes complete automation in the sample detection process, but also greatly shortens the detection time. It is the best choice for solar cell manufacturers! In the future, Millennial Solar will continue to uphold the belief of putting high efficiency first and provide high-performance testing products to solar cell manufacturers!