Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Effect of Screen Printing Process of Crystalline Silicon Solar Cells

Date : 14 November 2023Views : 810

In the production process of crystalline silicon solar cells, the impact of the screen printing process on their surface characteristics and performance is usually very direct and critical. Therefore, in order to understand the impact of screen printing on the surface characteristics and performance of solar cells, and to scientifically characterize the grid line parameters and solar cell performance after printing, Solar cell manufacturers often use sophisticated testing equipment to carry out targeted testing. Automatic Image Measuring Instrument produced by Millennial Solar, this equipment can characterize screen-printed grid lines through fast and accurate sub-pixel measurement functions, and can also use exclusive metal coverage measurement to conduct extensive testing of the photoelectric performance of crystalline silicon solar cells. With its many advantages, it helps photovoltaic enterprise users indirectly improve the quality of screen printing processes!

![]()

Basic working principles of screen printing process

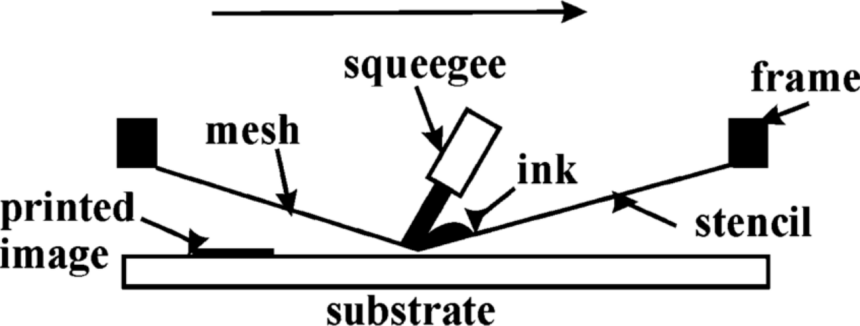

Screen printing involves attaching a template with an image or pattern to a screen for printing. Typically, screen printing screens are made of nylon, polyester, silk or metal mesh. When the substrate is placed directly under the screen printing screen with the template, the screen printing ink or paint passes through the mesh in the middle of the screen printing screen under the squeeze of the scraper and is printed on the substrate. The template on the screen printing screen seals part of the screen holes so that the paint cannot pass through the screen printing screen, but only the image part can pass through, so only the image part is imprinted on the substrate. In other words, screen printing actually uses ink to penetrate through the printing plate to print.

Screen printing process schematic diagram

![]()

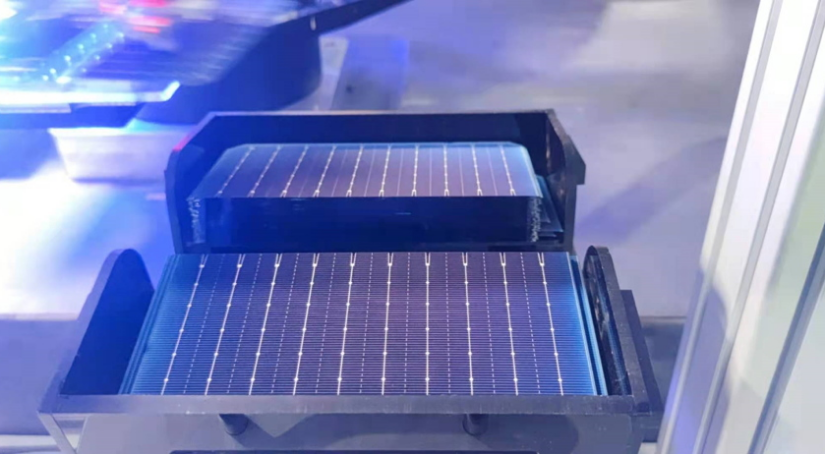

Effect of screen printing on surface morphology of crystalline silicon solar cells

The screen printing process will affect the surface morphology of crystalline silicon solar cells, including the thickness, width, spacing, and shape of the electrodes. These parameters will affect the optical properties of solar cells, such as reflectivity, transmittance, absorptivity, etc., and thus affect the photoelectric conversion rate of solar cells. Normally, the smaller the thickness and width of the electrodes, the larger the spacing, and the more regular the shape, the better the optical performance of the solar cell will be, because this can effectively reduce the blocking and reflection of incident light by the electrodes, and increase the effective absorption area of crystalline silicon.

![]()

Effect of screen printing on optical properties of crystalline silicon solar cells

The screen printing process will affect the electrical properties of crystalline silicon solar cells, such as electrode resistance, contact resistance, series resistance, distributed resistance, etc. Parameters such as the resistance, contact resistance, series resistance, and distributed resistance of the solar cell will affect the current, voltage, power and other output characteristics of the solar cell, thereby affecting the photoelectric conversion rate of the solar cell. Generally speaking, the smaller the resistance of the electrode, the smaller the contact resistance, the smaller the series resistance, the more uniform the distributed resistance, and the better the electrical performance of the solar cell. Because this can reduce the electrode's obstruction and loss of current and increase the effective output power of the solar cell. From this perspective, the screen printing process has an important impact on the optical performance of crystalline silicon solar cells.

![]()

Automatic Image Measuring Instrument——Scientific evaluation of screen printing process quality

Due to the impact of the screen printing process on the surface morphology and electrical properties of crystalline silicon solar cells, there is no scientific data to intuitively evaluate changes in performance after the cells are affected by screen printing. Therefore, Millennial Solar produced the Automatic Image Measuring Instrument, which can detect the busbars and grid lines formed after the screen printing process through its own unique high-precision detection technology that is rarely found in other such equipment. This helps photovoltaic enterprise users improve the screen printing process through measurement.

E-mail: market@millennialsolar.cn

Automatic Image Measuring Instrument VMM Pro is used to detect the image and 2D plane of photovoltaic screens, as well as photovoltaic cell grid line width, spacing, printing effects, etc. The equipment is equipped with a measurement system based on a high-resolution camera, can quickly and accurately measure various parts.

VMM Pro is installed with a variety of lighting and can provide a variety of lighting combinations to meet different lighting needs. Help photovoltaic manufacturers improve screen printing processes and increase production rates.

● Use LED light source to achieve various lighting combinations

● Sub-pixel measurement function, focus repeatability can reach 0.002mm~0.003mm

● Using LED optical system, display resolution can reach 0.0001mm

● Provide one-click data visualization function software

Production and testing are indispensable. The screen printing process must be evaluated through quality testing of solar cells. Otherwise, various problems will occur when the solar cells are put into use after production. Millennial Solar has developed the Automatic Image Measuring Instrument for this purpose. This equipment can evaluate the performance of solar cells by measuring the width, height, upper and lower PT values, left and right PT values of photovoltaic grids and other parameters, thus helping solar cell manufacturers to improve the production of solar cells !