Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Solar Cell Electrode Manufacturing Process, How Should We Choose Electrode Materials?

Date : 22 November 2023Views : 810

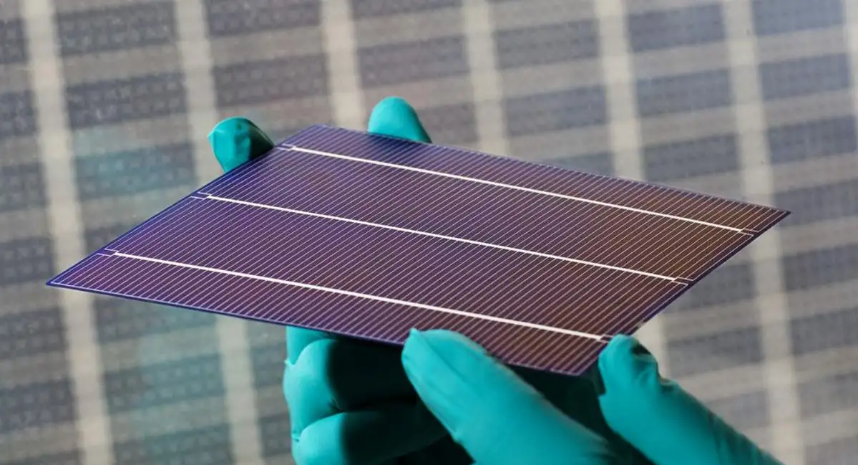

The production of solar cell electrodes is an important link in the solar cell manufacturing process, which will directly affect the performance and stability of solar cells. During its production process, the selection of solar cell electrode materials is particularly important. The selection of electrode materials should be optimized and matched according to the type and needs of the solar cell, so as to achieve the best photoelectric conversion rate. The TLM Contact Resistance Tester produced by Millennial Solar can perfectly evaluate the process quality of the solar electrode manufacturing process, so that after the process is completed, scientifically characterize parameters such as solar cell contact resistance, sheet resistance, contact resistivity and grid line resistance. Thus helping solar cell manufacturers to better produce solar cells!

![]()

Solar cell electrode manufacturing process principle

The electrode of a solar cell refers to the output end of the solar cell, which is usually composed of transparent, metal or carbon materials. Different materials have different advantages and disadvantages, such as light transmittance, conductivity, temperature resistance, etc. In the production of solar cell electrodes, it is first necessary to select appropriate substrate materials, such as silicon, glass, ceramics, etc., to provide good optical and electrical properties. The choice of electrode material is also very important. We can choose ITO film, metal film, or carbon, etc., and then the electrode material can be deposited on the substrate through various deposition methods to form a uniform, dense and high-quality electrode layer. Finally, the electrode layer needs to be surface treated and tested to optimize its optical and electrical properties and to detect parameters such as its photogenerated carriers and no-load current.

![]()

Solar cell electrode material selection principles

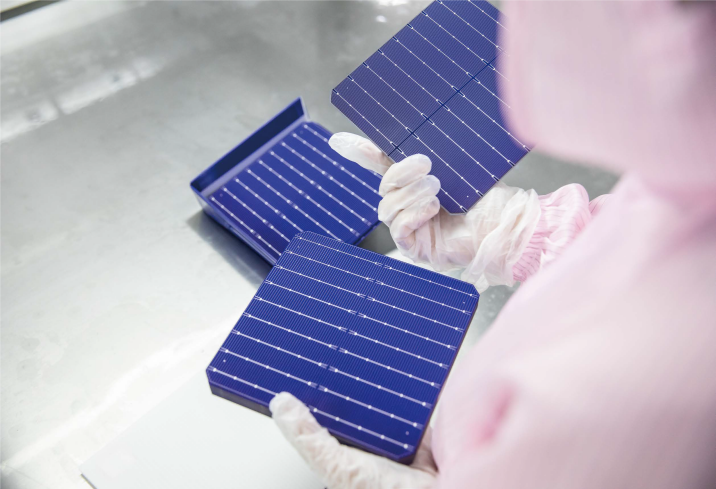

Optimize and match according to the type and needs of solar cells to achieve the best photoelectric conversion effect. For crystalline silicon solar cells, silver and aluminum are generally chosen as positive and negative electrode materials to provide efficient photogenerated current and back surface fields; for thin film solar cells, ITO and carbon are generally chosen as positive and negative electrode materials to provide high transmittance and low-cost electronic transmission and contact.

Consider the conductivity, reflectivity, light transmittance, stability, cost and other factors of the electrode material to balance the performance and economy of the electrode. Usually, metal or ITO film materials with high conductivity and high reflectivity are selected for the front electrode, thereby improving photoelectric conversion efficiency and output power; while carbon materials with low conductivity and low cost are generally selected for the back electrode. To reduce electrode losses and costs.

Consider the matching of electrode materials and solar cells to avoid problems such as reactions, dead zones, and defects between the electrodes and silicon wafers, which will affect the life and performance of the electrodes. For silicon wafers, metal or ITO film materials with good ohmic contact and chemical stability are generally selected to ensure the reliability and durability of the electrodes; for non-silicon wafers, materials with non-silicon wafers are generally selected. Silicon wafers have good interface compatibility and physical stability with metal or carbon materials, thereby ensuring the life and stability of the electrode.

![]()

TLM Contact Resistance Tester

Whether it is the selection of solar cell electrode materials or the optimization of the process during electrode production, the goal is to increase the contact resistance of the solar cell as much as possible after the process is completed. Then, in order to understand the growth of the contact resistance to the greatest extent, use the TLM Contact Resistance Tester produced by Millennial Solar to conduct high-precision and scientific measurements.

E-mail: market@millennialsolar.cn

In solar cell electrode optimization, contact resistance is an important aspect that needs to be considered. The contact resistance is not only related to the contacted image, but also related to the diffusion process and sintering process. Using the TLM Contact Resistance Tester produced by Millennial Solar to measure contact resistivity can reflect problems in diffusion, electrode production, sintering and other processes. And the contact resistivity test and line resistance test provided by this equipment can be switched at will.

● The test range can reach 0.1~120mΩ*cm^2

● Static test repeatability ≤1%, dynamic test repeatability ≤3%

● Line resistance measurement accuracy can reach 5% or 0.1Ω/cm

● Contact resistivity test and line resistance test can be switched at will

● A variety of probe heads can be customized for measurement and analysis

In order to maximize the use value of solar cells, it is particularly important to select electrode materials. Millennial Solar's TLM Contact Resistance Tester can evaluate and characterize the contact resistance of the solar cell after selecting the electrode material to evaluate whether the selected electrode material is the most suitable, thereby helping solar cell manufacturers optimize the electrode material!