Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

PERC Leads the Solar Cell Market!

Date : 24 November 2023Views : 785

High-quality solar cells often use their significant advantages to win the favor of the photovoltaic market. As the leader in the solar cell market, PERC cells have many advantages that cannot be ignored and have always dominated the solar cell market. The 3D Microscope owned by Millennial Solar can easily detect the grid lines and textured surface of PERC solar cells, helping solar cell manufacturers to better perform cleaning, texturing and screen printing to ensure the cell quality of PERC cells.

![]()

What is PERC?

PERC (Passivated Emitter and Rear Cell), which stands for "Emitter and Back Passivated Cell", is naturally derived from the conventional aluminum back field cell (BSF) structure. Because the recombination speed in the metal aluminum film layer on the back surface of conventional BSF cells cannot be reduced to less than 200cm/s, only 60%-70% of the infrared radiation reaching the aluminum back layer can be reflected, resulting in more photoelectric losses. Therefore, there are inherent limitations in the photoelectric conversion rate; solar panels made of PERC cells have an extra layer on the back of traditional solar cells. This extra layer captures more sunlight and converts it into electricity, making PERC cells more efficient than traditional cells. PERC also mitigates backside recombination and prevents longer wavelength heat from becoming heat that can harm cell performance.

![]()

Why you need to know about PERC

Everything must have its inherent cause and effect. Under today's development trend, the audience of PERC cells in the photovoltaic market has grown exponentially, and the PERC photovoltaic module production line has almost become a must-have for mainstream module manufacturers. Its efficiency is 1% or more higher than traditional photovoltaic modules. The PERC structure can break through the physical efficiency achieved by traditional photovoltaic cells and enable module manufacturers to improve higher module conversion efficiency. According to analysis, the market share of PERC photovoltaic modules will increase significantly in the next few years, becoming a mainstream supply commodity.

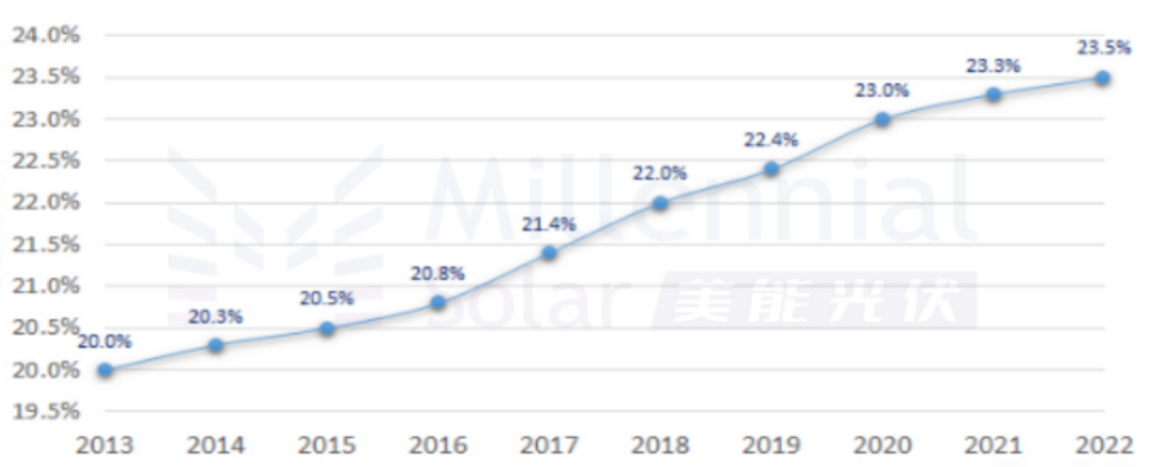

Mass production efficiency of PERC cells

![]()

Cost reduction and growth promote technology iteration, PERC is still the mainstream of the market

PERC technology relies on its strong cost-effective advantages and production capacity layout. At least in the next three years or even for a long period of time, it will still be the mainstream technology in the industry, and manufacturers will actively improve efficiency and reduce costs to extend its life cycle. According to public information predictions, by 2025, the market share of PERC cells will still exceed 50%.

![]()

3D Microscope

E-mail: market@millennialsolar.cn

3D Microscope is an optical instrument specially used in the photovoltaic industry to inspect the quality of grid lines on the surface of photovoltaic cells. Based on the principle of optical technology, combined with precision Z-direction scanning module, 3D modeling algorithm, etc., the device surface is non-contactly scanned and a 3D image of the surface is established. Through the system software, the height and width of the grid lines on the photovoltaic cells can be adjusted. The number of pyramids on the textured surface is quantitatively detected, to provide feedback on the quality of photovoltaic cell cleaning, texturing and screen printing processes.

As a high-efficiency solar cell, PERC cells are one of the important trends in the development of the solar cell industry. As the demand for renewable energy continues to increase, the market demand for solar cells is also growing. The emergence of PERC cells has greatly improved the efficiency and performance of solar cells. The 3D Microscope owned by Millennial Solar can easily detect the grating surface of PERC cells, allowing photovoltaic cell manufacturers to produce high-quality solar cells!