Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Thin Film Solar Cell Materials (Part 1)

Date : 1 December 2023Views : 885

There are several types of materials used to make thin film solar cells. In this section, we will explain cadmium telluride (CdTe) thin film cells as well as copper indium gallium selenide (CIGS) thin film cells. This issue of Millennial Solar will introduce photovoltaic materials technology.

![]()

Cadmium Telluride (CdTe) Thin Film Solar Cells

Cadmium telluride (CdTe) thin film solar technology was announced to the world in 1972 by Bonnet, D. and Rabenhorst, H., when they tested a cadmium sulfide (CdS)/CdTe heterojunction with an efficiency of 6%. The technology has been refined to reduce manufacturing costs and increase efficiency.

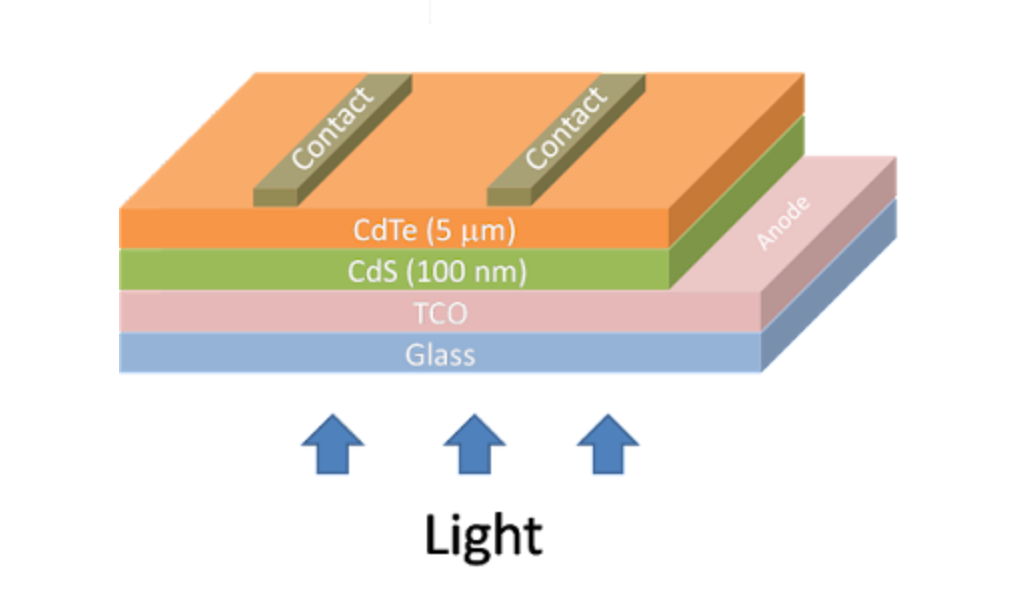

CdTe solar cells are manufactured using p-n heterojunctions that combine a p-doped cadmium telluride layer and an n-doped CdS layer, which can also be made from magnesium zinc oxide (MZO). To deposit materials on substrates, manufacturers use chemical vapor deposition techniques or close-range sublimation techniques. At the absorber layer, CdTe thin film solar cells include a transparent conductive oxide (TCO) layer usually made of fluorine-doped tin oxide (SnO2:F) or similar materials. The electrodes of these cells are made of zinc telluride (ZnTe).

CdTe thin-film solar panels achieved an efficiency of 19% under standard test conditions (STC), but crystalline silicon solar cells achieved an efficiency of 22.1%. The technology currently accounts for 5.1% of the global market share, second only to crystalline silicon solar panels, which account for 90.9% of the market. CdTe thin film solar panels cost approximately $0.40/watt.

CdTe Solar Cell Structure

![]()

Current Continuity Testing System

Current Continuity Testing System is specially designed for the 10.11 high and low temperature cycle test clauses and 10.12 humidity and freezing test clauses in the IEC61215 standard. It mainly includes providing stable DC power, current recording, temperature recording and temperature control functions. Through temperature control of the DC power supply, it can monitor multiple currents and temperatures in real time for a long time. Used in conjunction with the environmental chamber, it can monitor the internal circuit continuity of multiple photovoltaic modules. Determine the fatigue resistance of the material, the rationality of the lamination process, and the stability of the welding quality of the solar cell module in high and low temperature alternating environments.

E-mail: market@millennialsolar.cn

![]()

Copper Indium Gallium Selenide (CIGS) Thin Film Solar Cells

CIS thin film solar cells were synthesized by Hahn, H in 1953. The first advances in copper indium gallium selenide (CIGS) thin-film solar cells came in 1981, when Boeing created a copper indium selenide (CuInSe2 or CIS) solar cell with an efficiency of 9.4%, and in 1995, the National Renewable Energy Experiment Researchers at NREL have created the first copper indium gallium selenide (CIGS) thin-film solar cell with a reported efficiency of 17.1%.

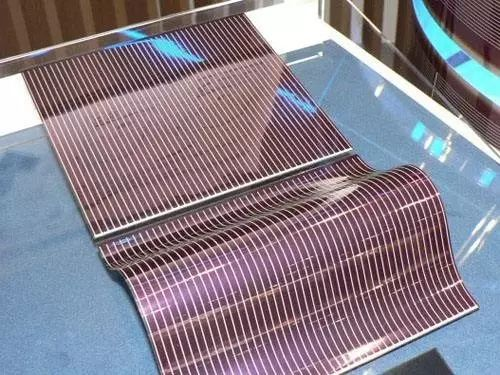

The manufacturing of copper indium gallium selenide (CIGS) thin film solar panels has improved throughout history. Currently, CIGS thin-film solar cells are manufactured by placing a molybdenum (Mo) electrode layer on a substrate through a sputtering process. The substrate is usually made of polyimide or metal foil. The absorber layer is fabricated by combining p-n heterojunctions. The P doping layer is made of copper indium gallium selenide (CIGS), plated on top of the electrode, and deposited through a chemical bath to form a CdSn doping buffer. To protect the absorber layer of CIGS thin-film solar panels, a layer of intrinsic zinc oxide (i-ZnO) is placed above the CdS buffer. These materials are ultimately covered with a thick layer of AZO compound made of aluminum-doped zinc oxide (Al:ZnO), which acts as a TCO layer to protect the solar cells. The first CIGS thin-film solar panel made by NREL had an efficiency of 17.1%, but the most efficient solar panel ever produced was 23.4% efficient and was made by Solar Frontier in 2019. CIGS technology may be more promising in the future, as these materials can achieve a theoretical efficiency of 33%. Mainly used in space applications due to their low temperature resistance and excellent performance in low-intensity light conditions in space, CIGS cells are not that popular in conventional applications. The cost is relatively expensive compared to other technologies, with current prices just over $0.60/watt, but future manufacturing generations promise to drive down the cost of these panels. Although CIGS thin-film solar panels are not yet as popular in the market as CdTe cells, CIGS technology still accounts for 2.0% of the photovoltaic market share. Considering that thin-film solar modules only account for about 10% of the market, this is still a very popular thin-film solar technology.

Thin film solar cells also have a variety of technologies. Today we shared and learned about two of the photovoltaic technologies. Millennial Solar will continue to share thin film solar cell materials in the next issue.