Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Monocrystalline and Polycrystalline Silicon

Date : 29 December 2023Views : 840

Everyone knows that solar panels are divided into monocrystalline, polycrystalline and amorphous silicon. Most solar panels now mainly use monocrystalline and polycrystalline as materials. Today Millennial Solar has compiled some knowledge points about monocrystalline silicon solar cells and polycrystalline silicon solar cells to share with you.

![]()

Monocrystalline silicon and polycrystalline silicon solar cells

Monocrystalline silicon solar cells are solar cells that use high-purity monocrystalline silicon rods as raw materials. They are currently the fastest developed type of solar cells. Its structure and production process have been finalized, and the product has been widely used in space and ground.

Polycrystalline silicon solar cells are a new generation of cells that combine the high conversion efficiency and long life of monocrystalline silicon cells with the relatively simplified material preparation process of amorphous silicon thin film cells. The conversion efficiency is generally about 17-18%, which is slightly lower than that of single-crystalline silicon solar cells. Crystalline silicon solar cells have no obvious efficiency degradation problem and can be produced on cheap substrate materials. Their cost is much lower than that of monocrystalline silicon cells and their efficiency is higher than that of amorphous silicon thin film cells.

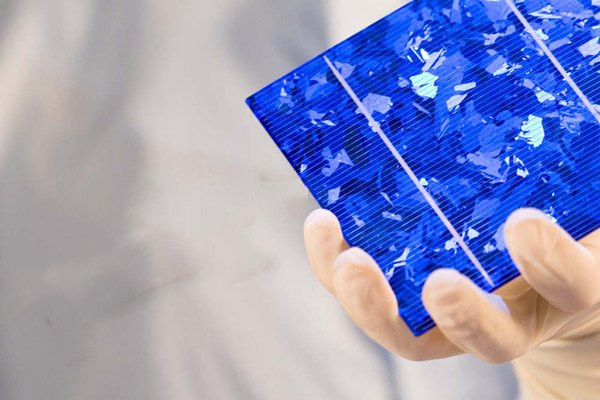

Simply put, the difference between monocrystalline silicon and polycrystalline silicon lies in their atomic structure arrangement. Single crystal is arranged in an orderly manner, while polycrystalline is arranged in a disordered manner. This is mainly determined by their processing technology. Polycrystalline is mostly produced by casting method. , which means directly pouring silicon material into a crucible to melt and shape, while single crystal adopts Siemens method to improve Czochralski. The Czochralski process is a process of reorganization of atomic structure. To our naked eyes, the surface of monocrystalline silicon looks the same, while the surface of polycrystalline silicon looks like there are a lot of broken glass inside, making it sparkly.

![]()

Main difference

Price: The cost of monocrystalline solar panels for sale is relatively high compared to polycrystalline solar panels for sale. You should conduct a careful cost-benefit analysis and determine your budget to make the right choice for you.

Efficiency: One of the main advantages of monocrystalline solar panels is their high efficiency. These products are made from high-quality silicone with a single-crystal structure. Therefore, the resistance of current flow in these cells is minimal. On the other hand, while one of the advantages of polycrystalline solar panels is their lower price, they are also less efficient (between 14% and 16%) due to reduced silicon purity.

Lifespan: When you compare the initial installation costs between monocrystalline and polycrystalline solar panels, you should also look at the average lifespan of each type of panel. Monocrystalline solar panel manufacturers typically offer a 25-year warranty because the product lasts longer. Polycrystalline solar panels do not differ much in this lifetime parameter, but the warranty period provided by the manufacturer may vary.

Temperature coefficient: In warm weather, monocrystalline solar panels can provide higher efficiency due to their higher temperature coefficient. As the temperature increases, the output degradation of monocrystalline panels is lower. If you live in an area with longer, warmer summers, you should carefully consider the temperature coefficient of the solar panels you choose.

Appearance: The aesthetic appearance of a solar panel depends on one's personal sense of aesthetics. But many users find that polysilicon's speckled blue tint is less easy on the eyes. Therefore, they may prefer monocrystalline solar panels as they find them more uniform in appearance and therefore aesthetically preferable.