Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

IBC Solar Cell Technology

Date : 3 January 2024Views : 910

IBC (Interdigitated back contact) cells appeared in the 1970s and were the earliest back-junction cells studied. They were initially mainly used in concentrator systems. IBC technology has obvious potential for efficiency improvement through process stacking, and it has potential for future industrialization.

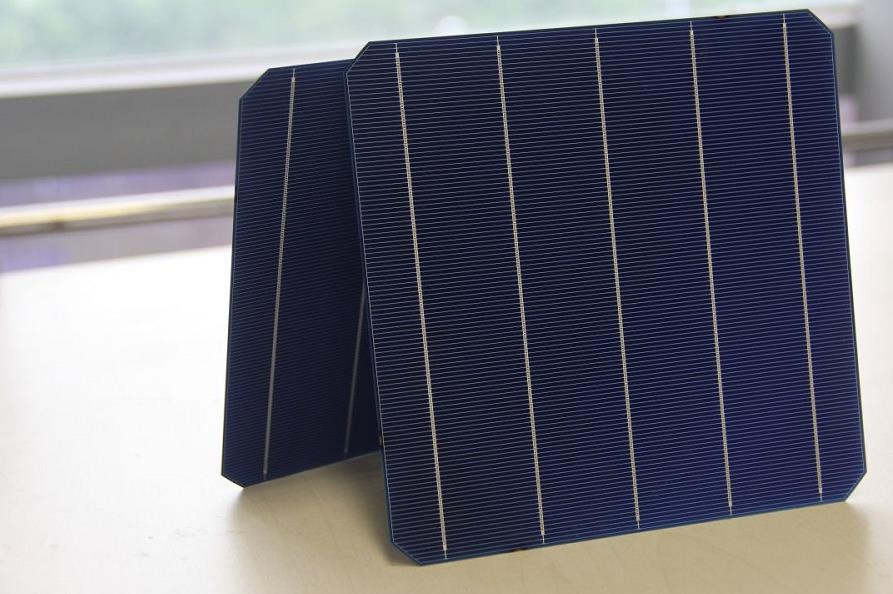

![]()

working principle

IBC solar cell technology refers to a back-junction solar cell structure with positive and negative metal electrodes arranged in an interdigitated manner on the backlight surface of the cell. Due to the high requirements on the minority carrier lifetime, IBC cells generally use N-type silicon wafers as the substrate, and the front surface is the N+ front field area FSF. The field passivation effect is used to reduce the surface minority carrier concentration, thereby reducing the surface recombination rate and also reducing the series connection rate. Resistance; SiO2/SiNx laminated films are used as passivation films on the front and rear surfaces to inhibit carrier recombination on the back surface of the IBC; the front surface is often covered with an anti-reflection layer to improve power generation efficiency; all metal contact parts are in contact with the positive and negative electrodes on the back regions are also arranged in an interdigitated shape.

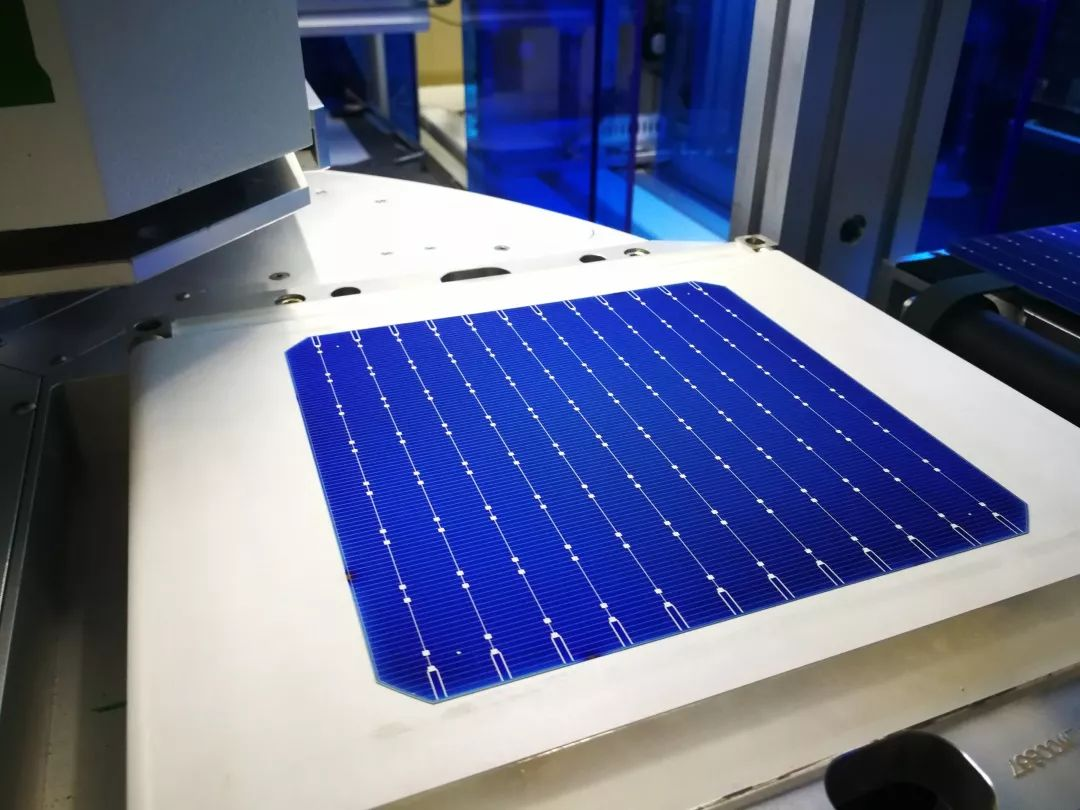

![]()

cell features

1. Compared with PERC, PERT and HJT cells, this has no grid lines on the front surface, and the positive and negative electrodes are prepared in a cross-arranged manner on the back of the battery, avoiding about 5% of the shading loss of conventional cell front grid lines.

2. The point contact connection between the metal electrode and the emitting area or base area is realized, which reduces the back surface recombination rate of photogenerated carriers.

3. Due to the back contact structure, the series resistance of IBC cells is lower than that of traditional cells and has a higher fill factor.

In addition, IBC cells can be superimposed with a variety of cell technologies to further improve efficiency: (1) Combined with TOPcon and HJT technologies to produce TBC (POLO-IBC) and HBC cells, the efficiency is increased to more than 26%; (2) Combined with perovskite technology, PSC IBC stacked cells are produced.

![]()

3D Microscope

The 3D Microscope ME-PT3000 is a high-speed confocal scanning microscope that can be used for accurate and reliable 3-dimensional (3D) measurements. Real-time confocal microscopy images are achieved through fast optical scanning modules and signal processing algorithms.

ME-PT3000 3D Microscope is an optical instrument specially used in the photovoltaic industry to inspect the quality of grid lines and textures on the surface of photovoltaic cells. Based on the principle of optical technology, combined with precision Z-direction scanning module, 3D modeling algorithm, etc., the device surface is non-contactly scanned and a 3D image of the surface is established. The height and width of the grid lines on the photovoltaic cells and the texture on the surface are measured through the system software. The number of pyramids is quantitatively tested to provide feedback on the quality of photovoltaic cell cleaning, texturing and screen printing processes.

E-mail:market@millennialsolar.cn

The cost of IBC cells has always been relatively high. With the entry of China's first-tier photovoltaic manufacturers and the development of new processes and new materials, IBC cells will continue to develop in the direction of improving cell conversion efficiency and reducing cell manufacturing costs. Millennial Solar believes that the commercial application and promotion of IBC solar cells has broad prospects.