Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Learn More About the Sheet Resistance and Influencing Factors of ITO Films

Date : 9 January 2024Views : 1040

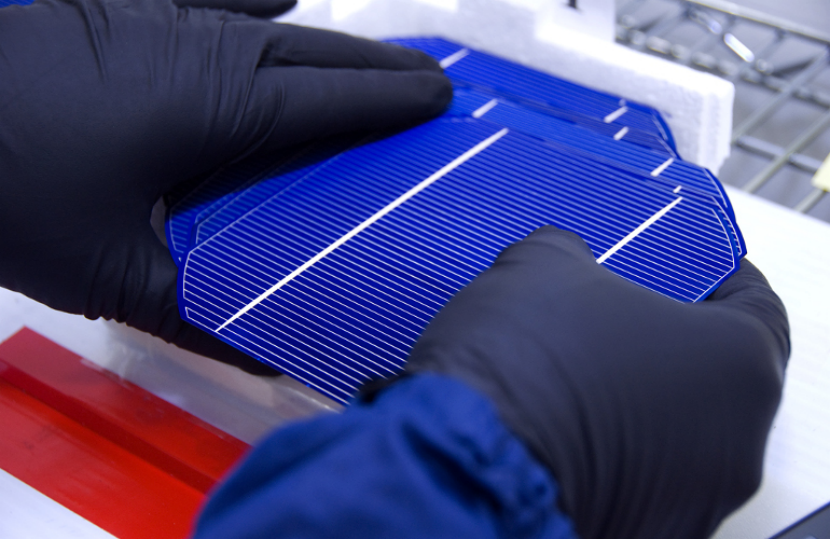

In the deposition process of solar cells, the preparation of high-performance ITO films is its primary task. When preparing ITO films, solar cell manufacturers often need to consider their own sheet resistance and factors that affect the sheet resistance of ITO films, so that they can better solve the factors that adversely affect the sheet resistance of ITO films based on their understanding. Improve the favorable influencing factors to produce high-quality solar cells. In order to help solar cell manufacturers scientifically understand the sheet resistance of ITO films, Millennial Solar has produced the Four-Point Probe Tester. This equipment can accurately detect the sheet resistance and resistivity of ITO films in solar cells, thereby helping solar cell manufacturers understand solar cells on the basis of the thin film, subsequent efficient production is carried out and put into use!

![]()

Sheet resistance of ITO film

ITO film is a transparent conductive film, mainly composed of indium oxide and tin oxide, and is widely used in the photovoltaic industry. The sheet resistance of an ITO film is the resistance value from edge to edge of a square ITO film. It is an important parameter to measure the conductive performance of the ITO film, and is also an important factor affecting the light transmittance and photoelectric conversion rate of the ITO film.

![]()

The concept and calculation method of sheet resistance of ITO film

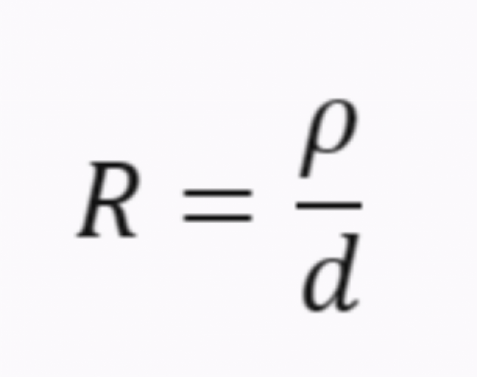

The sheet resistance of an ITO film refers to the resistance value from edge to edge of a square ITO film. It is related to the resistivity and film thickness of the ITO film and can be expressed by the formula:

Among them, R is the square resistance in ohms/square, ρ is the resistivity in ohms/meter; d is the film thickness in meters. It can be seen from the formula that in order to obtain lower sheet resistance, it is necessary to obtain lower resistivity and larger film thickness. The calculation method of sheet resistance is to use four probes to measure the resistance value on the ITO film, and then calculate the sheet resistance value based on the film thickness and the side length of the square.

![]()

ITO film resistance and influencing factors

The sheet resistance of ITO films is affected by many factors, including the following aspects.Composition of ITO film: The composition of ITO film is mainly the ratio of indium oxide and tin oxide, which is generally 9:1. The function of tin oxide is to provide carriers and increase the conductivity of the ITO film, but too much tin oxide will cause lattice distortion, reduce the crystallinity of the ITO film, and thereby increase the resistivity. Therefore, it is necessary to control the content of tin oxide while ensuring conductivity, generally between 5% and 15%.

Deposition process of ITO thin film: The deposition process of ITO thin film mainly includes deposition method, deposition temperature, deposition rate, deposition atmosphere, etc. Different deposition methods will affect the structure, morphology, orientation, etc. of the ITO film, thereby affecting the resistivity. Generally speaking, sputtering, evaporation, and chemical vapor deposition can be used to prepare ITO thin films, but sputtering is the most commonly used method because it can obtain a higher deposition rate and a more uniform film layer. .

The deposition temperature will affect the crystallization degree and grain size of the ITO film. Generally speaking, a higher deposition temperature is conducive to improving the crystallinity and grain size of the ITO film, thereby reducing the resistivity, but too high can also cause stress and defects in the film increase, thereby increasing resistivity. Therefore, it is necessary to select an appropriate deposition temperature based on different substrate materials and deposition methods, generally between 100°C and 500°C.

The deposition rate will affect the density and porosity of the ITO film. A lower deposition rate will help increase the density and porosity of the ITO film, thereby reducing the resistivity. However, a too low deposition rate will also reduce production efficiency and cost-effectiveness. Therefore, it is necessary to select an appropriate deposition rate according to different deposition methods, generally between 1nm/s and 10nm/s.

![]()

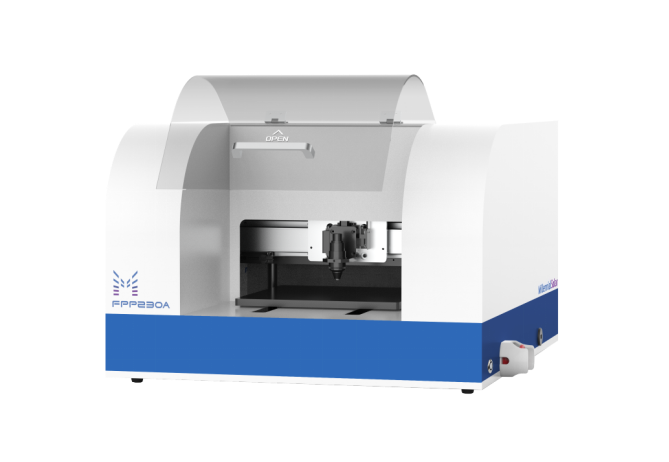

Four-Point Probe Tester

E-mail:market@millennialsolar.cn

Four-Point Probe Tester can quickly and automatically scan samples up to 230mm to obtain sheet resistance/resistivity distribution information at different locations of the sample. It can be widely used in photovoltaics, semiconductors, alloys, ceramics and many other fields.

● Ultra-high measurement range, measuring 0.1MΩ~100MΩ

● High-precision measurement, dynamic repeatability can reach 0.2%

● Fully automatic multi-point scanning, multiple preset schemes can also be customized and adjusted

● Rapid material characterization and automatic correction factor calculation

The deposition atmosphere will affect the oxygen content and oxygen vacancies of the ITO film. Generally speaking, a higher oxygen partial pressure will increase the oxygen content of the ITO film, thereby reducing the carrier concentration and resistivity.

However, too high oxygen partial pressure will also cause the light transmittance of the ITO film to decrease and the light absorption to increase. Therefore, it is necessary to select an appropriate oxygen partial pressure according to different deposition methods.

The sheet resistance and resistivity of ITO films, as important factors affecting the performance of solar cells, have always been focused on by solar cell manufacturers. Solar cell manufacturers usually have to use unique testing equipment to evaluate whether the quality of the deposition process meets industrial standards after completing the solar cell ITO thin film deposition process. Four-Point Probe Tester can help solar cell manufacturers evaluate the performance of ITO films more conveniently, efficiently and scientifically, and characterize the sheet resistance parameters of ITO films in each solar cell one by one, thus assisting their efficient production!