Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Monocrystalline Texturing Process

Date : 26 January 2024Views : 950

The cleaning and texturing process is also different when producing polycrystalline cells and monocrystalline cells. This issue of Millennial Solar will introduce to you the monocrystalline texturing process.

Principles and requirements of single crystal texturing

General requirements for textured surface: after texturing, there should be no obvious color difference on the surface of the silicon wafer; the textured surface should be small and uniform.

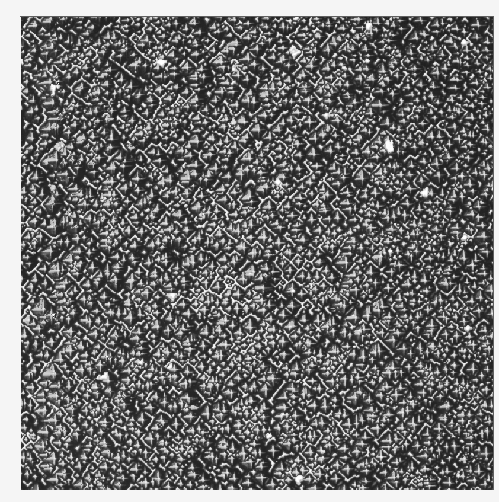

Single crystal texturing principle:

In short, it utilizes the anisotropic corrosion of silicon in low-concentration alkali solution, that is, the corrosion rate of silicon on the (110) and (100) crystal planes is much greater than the corrosion rate of the (111) crystal plane. After etching for a certain period of time, four pyramids composed of (111) faces are left on the surface of the (100) single crystal silicon wafer, which are the pyramids shown in the picture above.

According to literature reports, at lower concentrations, the maximum difference in silicon wafer corrosion rates can reach V(110):V(100):V(111)=400:200:1.

Although NaOH (KOH), Na2SiO3, IPA (or ethanol) mixed system texturing has been used in industry for nearly two decades, the anisotropic corrosion and texture formation mechanism explanation during the texturing process are still controversial. This article will List some mechanism explanations:

A. Pyramids are generated from defects in the silicon wafer;

B. Defects and surface contamination cause pyramid formation;

C. The silicon hydrate produced by the chemical reaction is not easily dissolved, leading to the formation of pyramids;

D. Isopropyl alcohol and sodium silicate are the causes of pyramids.

The preferential corrosion of silicon by alkali is the essence of pyramid formation. Defects, contamination, isopropyl alcohol and sodium silicate content will affect the continuity and size of the pyramid.

Influencing factors

The formation of single crystal texture ultimately depends on two factors: corrosion rate and anisotropy

Factors affecting corrosion rate:

1. The movement rate of the corrosive liquid to the surface of the corroded object;

2. The reaction rate of the chemical reaction between the corrosive liquid and the surface of the corroded object;

3. The rate at which products leave the surface of the corroded object.

Specific influencing factors of single crystal texturing:

NaOH concentration, solution temperature, isopropyl alcohol concentration, texturing time, sodium silicate content, tank sealing degree, isopropyl alcohol volatilization, stirring and bubbling.

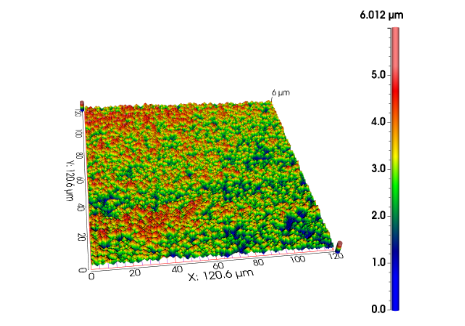

3D Microscope

The 3D Microscope ME-PT3000 is a high-speed confocal scanning microscope for accurate and reliable 3-dimensional (3D) measurements. Real-time confocal microscopy images are achieved through fast optical scanning modules and signal processing algorithms.

ME-PT3000 3D Microscope is an optical instrument specially used in the photovoltaic industry for quality inspection of grid lines and textured surfaces on the surface of photovoltaic cells. Based on the principle of optical technology, combined with precision Z-direction scanning module, 3D modeling algorithm, etc., the device surface is non-contactly scanned and a 3D image of the surface is established. The height and width of the grid lines on the photovoltaic cells and the textured surface are measured through the system software. The number of pyramids is quantitatively tested to provide feedback on the quality of photovoltaic cell cleaning, texturing and screen printing processes.

E-mail: market@millennialsolar.com

Every factor in monocrystal texturing will affect the final texturing effect. Different factors will cause the final film to be less than perfect. If you are interested in the specific effects, you can contact Millennial Solar for in-depth discussion.