Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Development Prospects of N-type TOPCon Cell

Date : 29 January 2024Views : 915

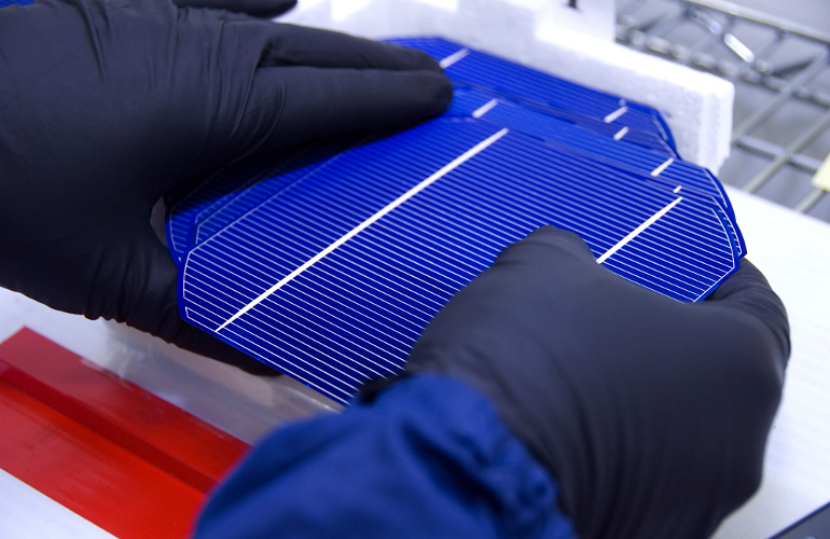

Among N-type technologies, TOPCon has proven that it has the same or even better profitability than PERC. During the technology iteration window period from P to N-type, traditional photovoltaic manufacturers have aggressively expanded TOPCon production capacity to consolidate their market position. In this issue of Millennial Solar, we will take you to understand TOPCon cell technology and development prospects.

TOPCon cell technology

The full name of TOPCon is Tunnel Oxide Passivating Contacts, which is a more advanced N-type silicon wafer cell technology proposed in 2013. Topcon cells are tunnel oxide passivated contact solar cells, which aim to improve cell efficiency by solving the problem of carrier selective passivation contacts.

TOPCon cell advantages

Higher efficiency ceiling

The theoretical efficiency limit of TOPCon solar cells is set at 28.2%-28.7% by scientific research in the field. This exceeds the heterojunction's 27.5% and is much higher than the PERC cell's 24.5%. It is closer to the theoretical limit of all crystalline silicon solar cells, which is 29.43%.

Excellent low light performance

TOPCon cells can maintain high conversion efficiency under low light conditions and are less susceptible to weather effects than PERC cells.

Can be upgraded and transformed based on PERC production line

TOPCon cells only have an additional manufacturing process than mature PERC cells. The added or replaced equipment is boron diffusion, equipment for tunneling oxide layers and polysilicon layer preparation. The rest of the process is basically compatible with the PERC production line. This means TOPCon solar cells can be upgraded from existing PERC production lines.

Since P-type cells are close to the theoretical efficiency limit, TOPCon is currently the technology route choice for rapid industrialization and is also a cost-effective development route.

3D Microscope

E-mail: market@millennialsolar.com

3D Microscope is an optical instrument specially used in the photovoltaic industry to inspect the quality of grid lines and textures on the surface of photovoltaic cells. Based on the principle of optical technology, combined with precision Z-direction scanning module, 3D modeling algorithm, etc., the device surface is non-contactly scanned and a 3D image of the surface is established. The height and width of the grid lines on the photovoltaic cells and the texture on the surface are measured through the system software. The number of pyramids is quantitatively tested to provide feedback on the quality of photovoltaic cell cleaning, texturing and screen printing processes.

As demand in the global photovoltaic industry rises, policy fundamentals resonate, adding new increments to the industry. Major photovoltaic manufacturers are actively seeking technological breakthroughs. One of the most important directions is the TOPCon cell route, which has high efficiency and low cost performance, and can undertake the transformation and upgrading of the original PERC production line. TOPCon cells are accelerating the expansion of production. The entire industry chain is ushering in a new round of upgrading opportunities. Millennial Solar is committed to helping photovoltaic manufacturers improve the impact of each production process on the efficiency of cells, speed up the time required for the production process, and progress together with the global photovoltaic industry.