Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Optical Properties of ITO Films Under the Influence of Annealing Process Temperature

Date : 2 February 2024Views : 845

ITO film is an indium tin oxide semiconductor transparent conductive film. Its main advantage is its high transparency and conductivity. It can be used as a transparent electrode in photovoltaic cells. In TOPCon cell, adding ITO film can effectively improve the short-circuit current density and conversion efficiency of the cell, which is an effective way to improve the performance of TOPCon cell. Millennial UVN2800 spectrophotometer is a detection instrument used to measure the transmittance, reflectance and absorbance of thin film materials such as ITO, amorphous silicon, microcrystalline silicon, etc., with a wavelength range of 190 ~ 2800 nm, equipped with new control and data processing The software provides strong support for solar cell efficiency analysis.

Application and preparation of transparent conductive oxide films

Transparent conductive oxide films (TCO) are used as transparent electrodes and have become an important component of different optoelectronic devices, such as solar cells, light-emitting diodes, photodiodes, etc. To ensure high optical transparency, the resistivity of these electrodes should be minimized as much as possible.

Indium tin oxide (ITO) thin films are currently the most widely used material and can be prepared by various methods, including DC and radio frequency sputtering, reactive evaporation, pulsed laser ablation, electron beam evaporation, spray pyrolysis and sol-gel technology. During the preparation process, the electrical and optical properties of ITO films are highly sensitive to the preparation method, composition, oxygen partial pressure, substrate temperature, substrate type and annealing process. The microstructure of the film will also change with the change of annealing temperature.

Optical properties of ITO films

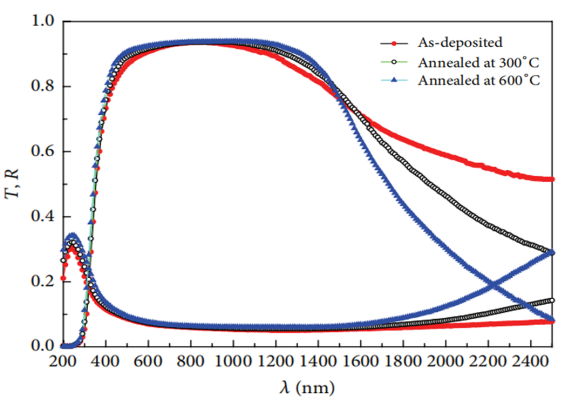

Information about transmittance is an important tool for determining the optical properties of ITO films. The figure below shows the transmittance and reflectance curves of deposited and annealed ITO films with a thickness of 199nm.

Transmittance and reflectance curves of ITO film with a thickness of 199nm

As can be seen from the figure, the ITO film exhibits high transmittance in the spectral range of 400~1300nm. Within the same spectral range, there is also a small increase in reflectance due to annealing. The results show that higher annealing temperatures lead to higher transmittance due to increased structural uniformity and crystallinity. As the crystal structure improves, light wave scattering decreases, allowing the film to have better transmittance.

In the spectral range of 1300~2500nm, the transmittance decreases significantly, while the reflectance of the annealed sample increases. This is due to the interaction of incident long-wave radiation with free electrons in the film.

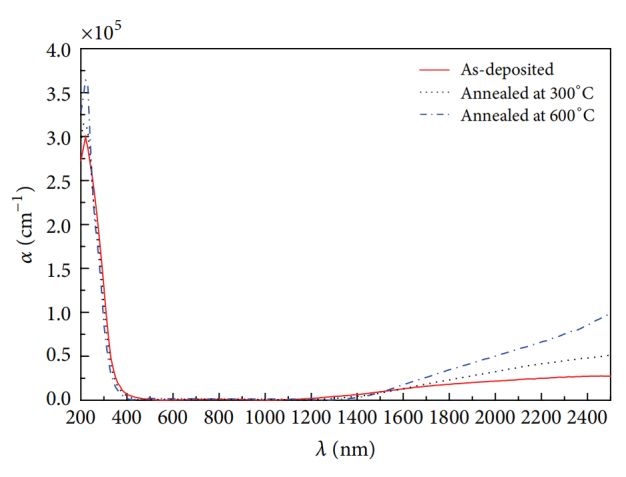

Absorption coefficient of 199nm thick ITO film

The figure above shows the effect of annealing temperature on the absorption coefficient spectrum of an ITO film with a thickness of 199nm. It can be seen that in the ultraviolet region, the absorption is strong due to excitation across the fundamental band gap. In the wavelength range of 400~1240nm, the absorption is extremely low, that is, the transparent area. Finally, in the wavelength range of 1240~2500nm, the absorption coefficient increases by increasing annealing due to the increase in free carrier density.

Spectrophotometer UVN2800

E-mail: market@millennialsolar.com

Spectrophotometer supports the measurement of solar transmittance in a wide range of wavelengths from the ultraviolet region to the near-infrared region, providing strong support for solar cell efficiency analysis. The equipment adopts a unique dual-beam optical design, which can perfectly correct the absorbance changes of different sample matrices, so that the sample can be measured stably. It has the advantages of wide testing range, high precision and good stability.

●Dual light source dual detector

●Ultra-large wavelength range 190-2800nm

●Double grating optical structure effectively reduces stray light

●Integrating sphere diameter up to 100mm

●No yellowing and stable optical properties after long-term use

●Can minimize errors caused by detector switching

More research shows that in the annealing process, temperature control can optimize the structure and optical and electrical properties of ITO films, and plays an important role. These optimizations can greatly improve the performance of TOPCon cell. Millennial Solar has developed an optimized solution and testing equipment for the ITO anti-reflection layer - Spectrophotometer, to help customers improve the optical performance of the film and produce cells with better quality and higher conversion efficiency.