Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Study on the Effects of Deposition Temperature and Sputtering Power on the Properties of ITO Films

Date : 4 March 2024Views : 935

ITO films play a vital role in improving the efficiency of heterojunction solar cells, while optimizing the electrical and optical properties of ITO films to maximize the efficiency of solar cells. Deposition temperature and sputtering power are also important parameters in the preparation process of ITO films. Both have a great impact on the resistivity and transmittance of ITO films. Millennial Four Point Probe Tester can help users optimize the electrical characteristics of solar cells, and Millennial Spectrophotometer supports measurement in the ultraviolet to near-infrared region, opening up a new future for optical detection! This article will explain to you the effects of deposition temperature and sputtering power on the electrical and optical properties of ITO films.

Deposition temperature

1. Electrical properties

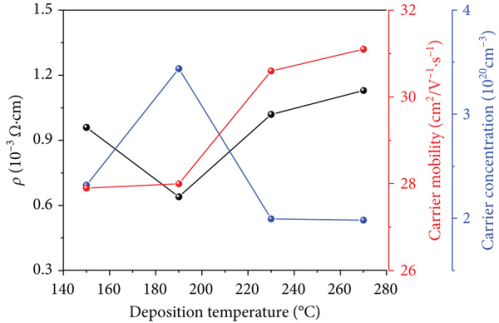

Deposition temperature affects the performance of ITO films by changing the microstructure during growth. As the deposition temperature increases, the carrier concentration first increases and then decreases, because when the deposition temperature increases, Sn4+ is more conducive to replacing In3+, thereby increasing carriers. When the temperature is 190°C, the carrier concentration decreases. This is because Sn can fully react with O2 at high temperatures to generate an oxide with a relatively complete composite stoichiometric ratio, resulting in a decrease in carrier concentration. However, the mobility increases with increasing deposition temperature and reaches a maximum value at 270°C. The reason is that an increase in deposition temperature increases crystallinity, which helps increase mobility.

Deposition temperature affects the electrical properties of ITO films

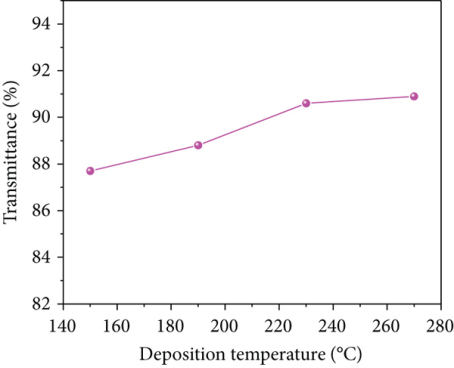

2. Optical properties

The transmittance of the ITO film increases as the deposition temperature increases, reaching a maximum value of 90.9% at 270°C. On the one hand, Sn4+ is more conducive to replacing In3+ at high deposition temperatures, thereby generating less low-priced brown oxides and thereby increasing visible light transmittance. On the other hand, it can improve crystallinity at high deposition temperatures.

Deposition temperature affects the optical properties of ITO films

Sputtering power

Sputtering power also plays a very important role in the conductive properties of the ITO film, which in turn affects the density of the ITO film and the adhesion to the silicon wafer by affecting the energy of the sputtered particles.

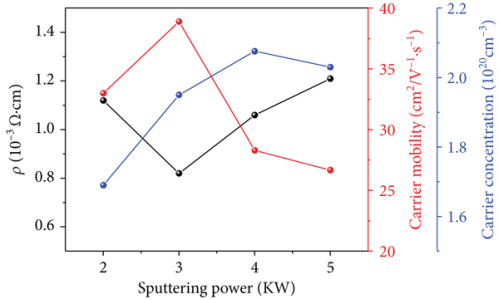

1. Electrical properties

Sputtering power affects the electrical properties of ITO films

As can be seen from the figure above, the carrier concentration increases with increasing sputtering power. Since higher sputtering power will produce a large number of sputtered particles, under the same oxygen content, the oxygen is not enough to fully oxidize the sputtered particles, thereby increasing the carrier concentration. As the sputtering power increases, the migration first increases and then decreases. As the sputtering power increases, argon ions can obtain higher energy, which is beneficial to improving the adhesion between the ITO film and the substrate, thus improving the crystal structure of the film and further increasing the carrier mobility. However, when the sputtering power continues to increase, the film will be damaged and the carrier mobility will decrease. Therefore, the resistivity of the ITO film first decreases and then increases as the sputtering power increases. Additionally, the sputtering power should not exceed the threshold. On the one hand, if the sputtering power is too high, high-energy particles will cause damage to the film, further affecting the conductive properties of the film. On the other hand, ceramic targets are highly brittle and can easily break when bombarded with high power.

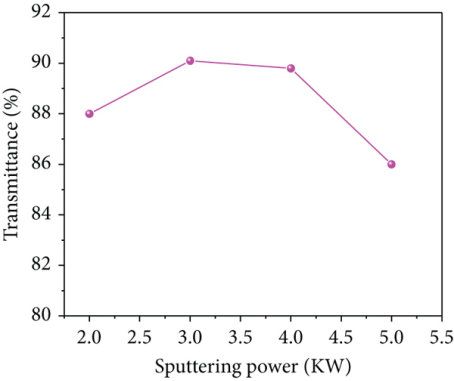

2. Optical properties

As the sputtering power increases, the transmission of the ITO film first increases and then decreases slightly. The sputtered particles are limited under low sputtering power, and the sputtered particles can be completely oxidized by oxygen to generate high-resistance, transparent oxide; therefore, the transmittance can reach more than 90%. However, as the sputtering power increases, the number of sputtered particles increases. When the oxygen content remains unchanged, only some particles are oxidized, resulting in a decrease in the transmittance of the ITO film. In addition, as the sputtering power increases, the carrier concentration reaches a maximum value, resulting in a decrease in transmittance.

Sputtering power affects the optical properties of ITO films

Four Point Probe Tester

E-mail: market@millennialsolar.com

Millennial Four Point Probe Tester can quickly and automatically scan samples up to 230×230mm to obtain sheet resistance/resistivity distribution information at different locations of the sample. It can be widely used in photovoltaics, semiconductors, alloys, ceramics and many other fields.

● Ultra-high measurement range, measuring 1mΩ~100MΩ

● High-precision measurement, dynamic repeatability can reach 0.2%

● Fully automatic multi-point scanning, multiple preset schemes can also be customized and adjusted

● Rapid material characterization and automatic correction factor calculation

Spectrophotometer

E-mail: market@millennialsolar.com

Millennial Spectrophotometer supports the measurement of solar transmittance in a wide range of wavelengths from the ultraviolet region to the near-infrared region, providing strong support for solar cell efficiency analysis. The equipment adopts a unique dual-beam optical design, which can perfectly correct the absorbance changes of different sample matrices, so that the sample can be measured stably. It has the advantages of wide testing range, high precision and good stability.

● Adopt dual light source and dual detector design, wavelength range 190-2800nm

●Double grating optical structure effectively reduces stray light

● The diameter of the integrating sphere can reach 100mm. It will not turn yellow after long-term use and has stable optical performance.

ITO film has excellent conductivity, transmittance and reflectivity, and its performance is determined by the preparation process. High efficiency and low cost have always been the goals pursued by the photovoltaic industry. Millennial Solar is willing to help users continue to make breakthroughs and innovations in the technical optimization of the electrical and optical performance of solar cells, achieve higher cell conversion efficiency, and work with users to advance technology in the photovoltaic industry. Keep moving forward on the road of development.

Part of this article is quoted from:

Guoping Huang, Guixiang Zhao, Xixi Huang, Hao Zhuang, Zhongjian Zhang, Ronggang Gao, Fengxian Xie, "Influence of Deposition Parameters of ITO Films on the Performance of HJT Solar Cells", International Journal of Photoenergy, vol. 2023, Article ID 1065503 , 8 pages, 2023. https://doi.org/10.1155/2023/1065503