Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Bypass Diode Testing and Thermal Runaway Principle

Date : 8 March 2024Views : 995

As solar power generation becomes more and more widely used, people have higher and higher requirements for the long-term durability of photovoltaic modules, among which bypass diodes play an important role in the performance of photovoltaic modules. To ensure efficient operation of photovoltaic systems, the thermal performance of bypass diodes must be accurately tested. This article will introduce Bypass Diode Thermal Tester from Millennial Solar and discuss the bypass diode test and thermal runaway principles.

IEC62790:2020 Bypass Diode Test Principle

IEC62790:2020 provides a transient method test scheme. This scheme uses the voltage drop UD across the bypass diode and the junction temperature Tj to form a linear relationship within a certain temperature range.

The junction temperature Tj is indirectly measured by measuring the voltage drop across the bypass diode.

Bypass diode testing process

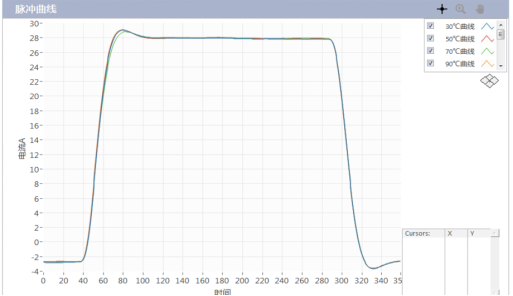

(1) After stabilizing the temperature of the environmental chamber to 30℃±2℃, use a bypass diode thermal performance tester to apply a pulse square wave current (pulse width 1ms) equal to the short-circuit current under STC to the sample, and read out the bypass The forward voltage drop of the diode UD1;

(2) After stabilizing the temperature of the environmental chamber to 50℃±2℃, repeat step 1 and read the forward voltage drop UD2 of the bypass diode;

(3) After stabilizing the temperature of the environmental chamber to 70℃±2℃, repeat step 1 and read the forward voltage drop UD3 of the bypass diode;

(4) After stabilizing the temperature of the environmental chamber to 90℃±2℃, repeat step 1 and read the forward voltage drop UD4 of the bypass diode;

Pulse graph

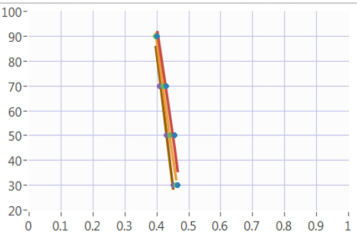

(5) Use the least squares method to obtain the relationship curve between the forward voltage drop UD of the bypass diode and the junction temperature Tj;

(6) After stabilizing the temperature of the environmental chamber to 75℃±5℃, apply a constant current equal to ±2% of the short-circuit current Isc under STC to the sample to be tested through a diode thermal performance tester. After powering on for 1 hour, read out the bypass. The forward voltage drop UD of the diode;

(7) Substitute the forward voltage drop UD into the relationship curve to obtain the junction temperature Tj of the bypass diode.

Fitted curve plot

Thermal runaway mechanism of diode

Some bypass diodes in photovoltaic modules have the characteristic that the reverse current increases with temperature in the reverse biased state. If the bypass diode is already in a very high temperature environment when it transitions to reverse bias, there may be a large reverse current inside the diode, and this reverse current may cause the diode temperature to further increase. When the temperature rise exceeds the heat dissipation capacity of the junction box, the temperature rise and reverse current will cause the bypass diode to fail, leading to very serious consequences. This phenomenon is called "thermal runaway." Therefore, the thermal design of the bypass diode in the junction box of the photovoltaic module should be tested to ensure that thermal runaway does not occur.

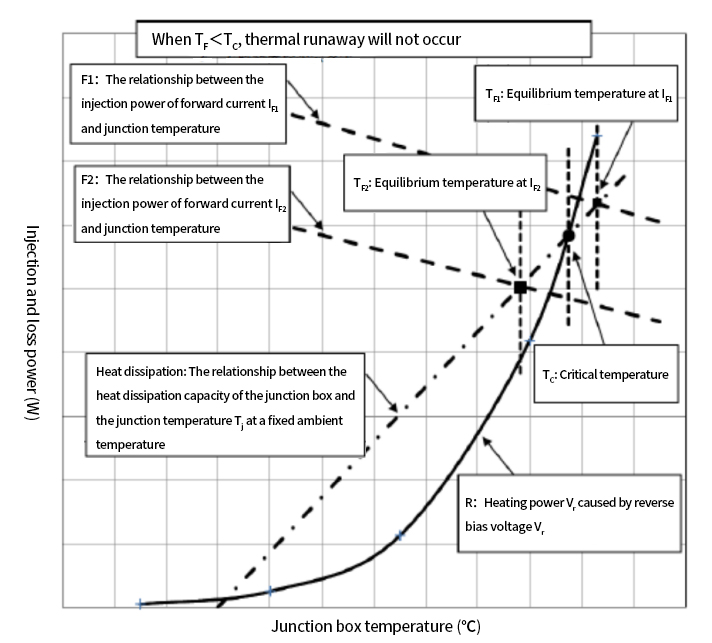

Schematic diagram of thermal runaway phenomenon

Curve R represents the relationship between input power and junction temperature caused by reverse bias. As shown in the figure, in the high junction temperature area, the input power rises very quickly. The heat dissipation capacity of the junction box is represented by the "heat dissipation" curve in the figure. The intersection of the "heat dissipation" curve and the curve R is the critical temperature Tc.

When the junction temperature is higher than the critical temperature Tc, the bypass diode is reverse biased, and the input power will exceed the heat dissipation capacity of the junction box, causing the junction temperature to continue to rise until thermal runaway occurs.

When the junction temperature is lower than the critical temperature, the diode is reverse biased and the input power will be lower than the heat dissipation capacity. In this case, the junction temperature will gradually drop to the ambient temperature. Curves F1 and F2 represent the relationship between the input power generated by forward currents IF1 and IF2 and the junction temperature. Its intersection with the Thermal Dissipation curve shows the equilibrium temperature at forward bias.

Bypass Diode Thermal Tester

E-mail: market@millennialsolar.com

Introduce:

Bypass Diode Thermal Tester uses the pulse current method to obtain the relationship between the diode voltage drop and temperature, and then obtains the junction temperature of the diode in the constant current state. This equipment also has the function of testing the forward volt-ampere characteristics of the diode and testing the thermal runaway of the diode. Monitor the surface temperature of the diode and the surface of the component, monitor the diode current and the voltage drop across the diode; monitor the reverse leakage current of the diode.

Fulfill the standard:

Meet IEC61215-MQT18 and IEC61730-MST07, MST25, IEC62979

Features:

•The application of reverse power can be controlled by time

•Automatically simulate the relationship between UD and Tj using the least squares method

•Reverse voltage application can be automatically controlled through temperature change trends

•Get UD data at 75℃, ID=Isc, and calculate Tj value at 75℃

•Record the changes in voltage and current across the diode during rapid changes in the circuit

•In the pulse current stage, collect parameters such as pulse current, diode voltage drop, junction box temperature, etc.

•Real-time display of voltage and current (including leakage current) change curves during the voltage conversion process, and the curves can be exported

Bypass Diode Thermal Tester provides important support for improving the performance of photovoltaic systems. By accurately testing the thermal performance of the bypass diode, not only can problems be discovered in time and measures can be taken to ensure the long-term stable operation of the system, but the working status of the photovoltaic system can also be better understood and the efficiency and reliability of the system can be improved. In the future, with the continuous advancement of technology and the continuous improvement of equipment, Millennial Solar will play an increasingly important role in the industry, assisting the development and application of clean energy and contributing to the development of sustainable energy.