Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

TOPCon Cell UV Attenuation Degradation Risk

Date : 15 April 2024Views : 785

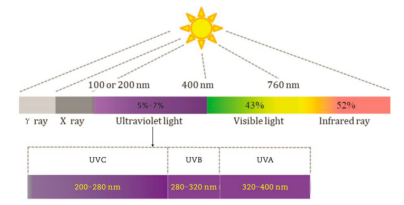

With the rapid development of the photovoltaic industry, the industry's quality requirements for solar cells and photovoltaic modules are getting higher and higher. When photovoltaic modules are actually used in real environments, they will be affected by ultraviolet radiation, mechanical loads from wind and snow, wind and sand impact, acid rain corrosion, etc.

With the rapid development of the photovoltaic industry, the industry's quality requirements for solar cells and photovoltaic modules are getting higher and higher. When photovoltaic modules are actually used in real environments, they will be affected by ultraviolet radiation, mechanical loads from wind and snow, wind and sand impact, acid rain corrosion, etc.

On June 29, 2022, the "PV Module Index 2022" study released by the U.S. Renewable Energy Testing Center (RETC) pointed out that cells manufactured with TOPCon technology are affected by ultraviolet (UV) radiation and may be at risk of premature degradation.

In the industry trend column, RETC introduced the industry's accelerating iteration to N-type technology, and introduced the advantages and future prospects of N-type cells. However, it also proposed the potential risks of new technologies, especially N-type TOPCon. Effects on cells during ultraviolet attenuation testing (UVID). The original text is as follows:

Risks of early deployment of TOPCon

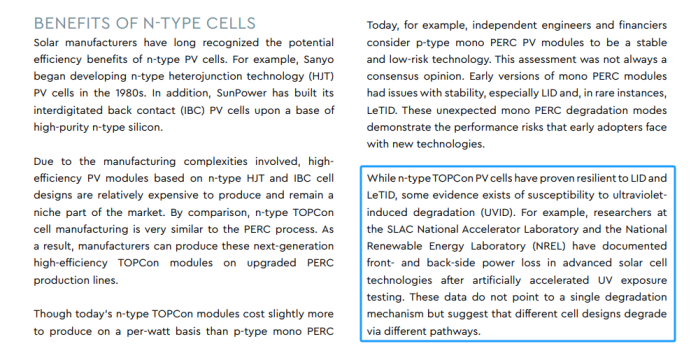

Most analysts expect that based on these performance advantages, modules with N-type TOPCon cells will rapidly increase market share. However, emerging photovoltaic cell technologies always carry potential risks, including the possibility of undiscovered degradation mechanisms before large-scale deployment.

Relative to p-type single PERC cells, the main material advantage of n-type TOPCon cells is a lower degradation rate due to reduced susceptibility to light-induced degradation (LID) and high-temperature-induced degradation (LeTID). Other advantages may include a higher duplexity factor, and improved performance in low-light and high-temperature conditions.

RETC noted that although N-type TOPCon photovoltaic cells have been shown to be insensitive to LID and LeTID, there is some evidence that they are susceptible to ultraviolet attenuation testing (UVID). For example, researchers at the SLAC National Accelerator Laboratory and the National Renewable Energy Laboratory (NREL) have documented front- and back-side power losses in advanced solar cell technologies after artificially accelerated ultraviolet exposure testing. These data do not point to a single degradation mechanism. But it shows that different cell designs degrade through different pathways.

Meanwhile, VDE Americas’ Sauer said, “As part of the technical due diligence, I recommend accelerated UVID testing of new N-type modules. If the cell passivation layers are not properly adjusted, they may break down under UV exposure. Given the high risks involved, RETC is independently conducting highly accelerated UV testing of a variety of next-generation components designed with N-type cells. "

UV aging experiments can be used to detect whether solar cells and photovoltaic modules have anti-attenuation capabilities when exposed to high humidity and high UV radiation sites.

Cell UV aging test chamber

E-mail: market@millennialsolar.com

The Millennial cell UV aging test chamber monitors the changes in cells under light by simulating different lighting conditions. It can be used for photovoltaic cell product development and quality control or to evaluate changes in the durability of cells after composition.

●Irradiation area: 800mm×800mm (satisfies the test of 20 182 cells)

● Irradiance range: 800~1300W/㎡

● The lighting level reaches BBA level

● Equipped with an independent system that can independently adjust the irradiation intensity of each light source and the overall irradiation intensity

Millennial Solar is committed to the development of PERC, TOPCon, HJT, XBC, perovskite/tandem solar cell process control and testing equipment, and provides high-efficiency solar cell and module testing equipment and intelligent detection and analysis system solutions. The company has a complete testing center with a total value of more than 20 million yuan. The testing center can improve the testing of the entire cell process and the reliability testing of photovoltaic modules that comply with IEC standards after packaging is completed.