Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Mechanical Load Test Simulates Wind Pressure and Impact Resistance

Date : 17 May 2024Views : 1045

The trend of increasing the power and size of photovoltaic modules has become a trend. The modules will be subject to pressure from wind, snow, ice, etc. If the strength of the module does not meet the requirements, it will deform too much under pressure and may fail. Dynamic Mechanical Load Tester is widely used in structural design and evaluation. It simulates external forces under actual conditions through mechanical stress, and evaluates the ability of photovoltaic modules to resist wind pressure and impact in the natural environment, as well as the stability of the structure.

In the IEC standard, which is a common standard for photovoltaic module performance and safety testing in laboratory testing, mechanical load testing is specified in detail. For example, IEC TS 62782 is used to evaluate the ability of photovoltaic modules to withstand dynamic wind pressure, and the mechanical load test of MQT16 in IEC61215.

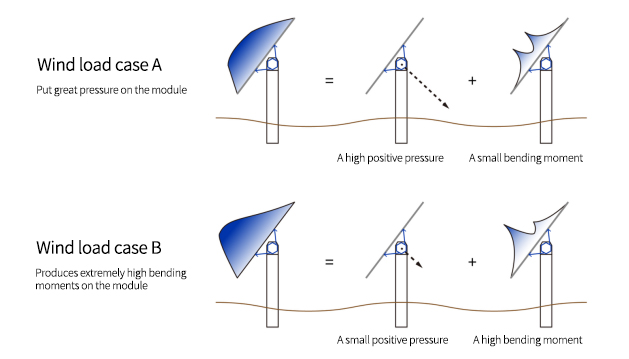

Wind load

It is not uncommon for photovoltaic modules to be damaged by strong winds during actual use. Although the effect of wind load is not as strong as other natural disasters, wind load acts frequently and is affected by the external environment and structural form. It is not easy to determine, which has a negative impact on photovoltaic modules. The harm produced is much greater. In photovoltaic power generation systems, photovoltaic modules are the first to bear wind load, occupying most of the force-bearing area, and then transferred to the basic structure (foundation, counterweight, etc.).

different wind loads produce two different forces on module

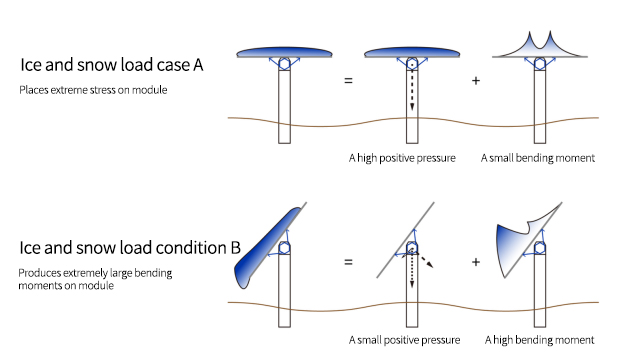

Ice and snow load

Heavy accumulation of ice and snow on component surfaces can cause stress. Mechanical load testing is used to evaluate the ability of photovoltaic modules to withstand pressure when encountering heavy snowfall, so as to more effectively avoid module failures caused by snow pressure, such as frame bending or breakage, uneven back glass cracks, and partial or complete installation systems. Disintegration etc.

different ice and snow loads produce two different forces on module

Mechanical load test

Before photovoltaic modules are put into field use, in order to avoid various faults and failures, it is necessary to ensure that the structure, materials, and production processes of the photovoltaic modules are reasonable and undergo a series of climate, light, electrical, and mechanical stress tests.

The mechanical stress test includes static and dynamic mechanical load tests, terminal strength tests and hail impact tests.

Static mechanical load, IEC61215 requires it to be at least 1.5 times the design load. By applying a certain load and measuring the displacement, stress and other parameters of the module, the maximum load-bearing capacity and deformation characteristics of the module can be determined. This is very important for designing and selecting modules suitable for specific application scenarios to ensure that they can safely and reliably withstand external mechanical loads in actual work.

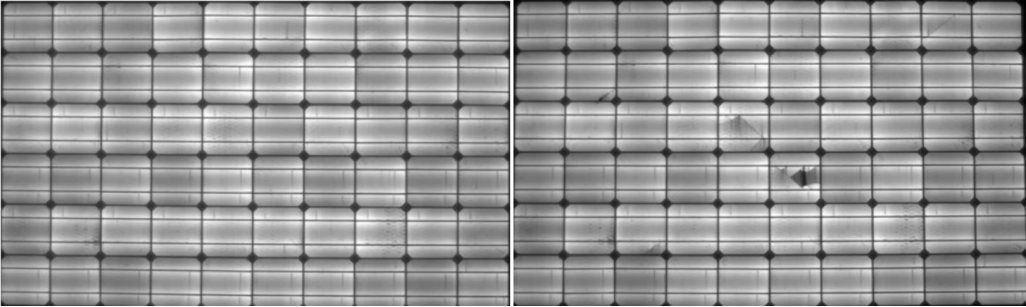

Dynamic mechanical load refers to the shaking of the front and rear surfaces of the module under the action of strong winds, which causes the module to undergo alternating pressure in the forward and reverse directions, thereby accelerating material fatigue and possibly causing the failure of fragile parts. Key factors affecting strength include module size, thickness, surface treatment, frame stability, installation method and mechanical reliability of welding points. The test helps evaluate the fatigue resistance of the module and the durability of the material, improving quality levels.

The mechanical load test in the existing standards mainly simulates the static load of the module and assesses whether the module is reliable under static and constant pressure. Dynamic mechanical load is more demanding than static mechanical load and can more objectively and comprehensively reflect the true reliability of the module. It is an excellent tool for manufacturers to measure the wind resistance of photovoltaic modules.

Comparison of EL images of unqualified modules before (left) and after (right) the dynamic mechanical load test

Dynamic Mechanical Load Tester

E-mail: market@millennialsolar.com

Dynamic Mechanical Load Tester has two test functions: static mechanical load test and dynamic mechanical load test. It tests the module's ability to withstand static and dynamic loads such as wind, snow, or ice. Dynamic pressure holding technology simulates the module to withstand alternating pressure tests in forward and reverse directions, accelerates module material fatigue, and tests the module's true reliability.

Load application method: the cylinder drives the suction cup to press and pull;

Equipped with 84 (12*7) cylinders, each cylinder is controlled individually;

Test system pressure, tension, holding time, cycle test, cycle frequency, and current values can be preset;

The testing system can record and store forward pressure, reverse pressure, deformation, temperature, number of cycles, and current values during the testing process.