Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Humidity Freeze Test Chamber: Environmental Simulation and Reliability Verification Based on PID

Date : 31 May 2024Views : 845

Solar modules need to withstand various harsh weather conditions during application, including extreme environmental conditions such as high temperature, high humidity and low temperature. Humidity Freeze Test Chamber uses advanced PID control technology to ensure the reliability and accuracy of the test. The PID control principle combines proportional, integral and differential algorithms to effectively adjust the temperature, prevent the evaporator from freezing, and ensure the smooth progress of humidity testing. Complies with IEC61215-MQT12 and IEC61730-MST52 international standards, and has anti-fatigue and anti-moisture penetration capabilities, verifying its superior performance and reliability in harsh environments.

PID control principle control and application

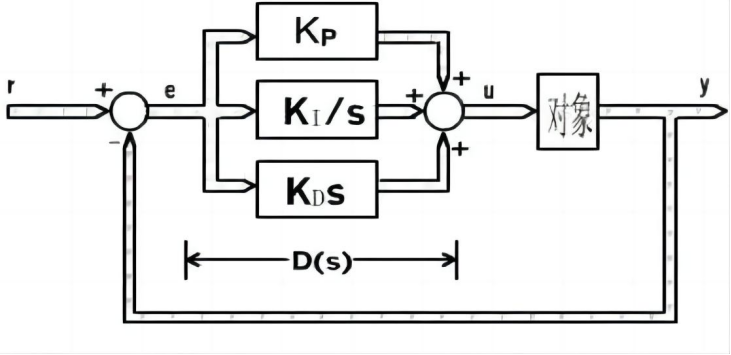

PID control principle is based on the combination of three control algorithms: proportional, integral and differential, which is used to achieve precise regulation of the controlled object. The PID controller calculates the deviation between the set point and the actual output value, and processes this deviation according to proportional, integral and differential, thereby generating a control signal to regulate the controlled object.

PID control system

Proportional control (P): Proportional control outputs a control amount proportional to the deviation based on the current deviation value. Its function is to quickly reduce the deviation, but since only the current deviation is considered, it may cause system oscillation or overshoot.

Integral control (I): Integral control accumulates all past deviation values and outputs a control amount proportional to the accumulated deviation. Its function is to eliminate steady-state errors and make the system reach the set point. However, excessive integral control may cause the system to respond more slowly.

Differential control (D): Differential control predicts future deviation changes and outputs a control amount proportional to future deviation changes. Its function is to prevent the increase of deviation in advance and improve the stability and response speed of the system.

In temperature control applications, the PID controller can achieve precise adjustment through the following steps:

Temperature detection: First, a temperature sensor is needed to monitor the temperature of the controlled object in real time and convert it into an electrical signal.

Error calculation: Compare the set target temperature with the actual measured temperature to calculate the current temperature deviation.

PID algorithm processing: Input the calculated deviation value into the PID controller, which processes the deviation value according to the three parameters of proportion, integration and differentiation to generate a control signal.

Actuator control: Output the control signal generated by the PID controller to the actuator, such as a solenoid valve or a heating wire. For example, if you want to adjust the cooling capacity, you can control the flow of refrigerant by changing the opening of the solenoid valve; if you want to adjust the heating capacity, you can control the heating value by changing the current of the heating wire.

Feedback loop: Feedback the actual output effect of the actuator to the temperature sensor, perform error calculation and PID processing again, and form a closed-loop feedback control system to achieve continuous and precise temperature adjustment.

According to the existing data, the segmented variable gain PID control scheme with dual feedback of superheat and compartment temperature deviation of the electronic expansion valve is analyzed and studied, and compared with the traditional fixed gain PID control scheme. The test results show that the variable gain PID control scheme is adopted in the environmental test chamber, and the cooling rate is increased by an average of 11.8% to 49.3%, the overshoot time is shortened by an average of 7.1% to 57.7%, the fluctuation of the compartment temperature during the constant temperature period is reduced to 0.1℃, and it has good adaptability to variable working conditions at different compartment temperatures of -40, -20, 0, and 20℃.

In this way, it is verified that the PID controller can effectively adjust the temperature and ensure that the controlled object maintains a stable temperature within the set range. Humidity Freeze Test Chamber adopts an intelligent energy-saving control method, and the PID controls the solenoid valve switch to output the cooling capacity according to the temperature demand in the chamber.

Determine the uniform critical frosting evaporation pressure range through experiments

Frosting is a common phenomenon in wet and cold environments. Frosting on the surface of the heat exchanger will cause hazards such as increased thermal resistance and blockage of the air flow channel. The understanding of the frosting law and the influence of surface characteristics on frosting on the cold surface, as well as the accurate simulation of the frost layer growth process, are of guiding significance for exploring suitable frost suppression methods and operating under low temperature and high humidity conditions.

In the simulation of the frost layer growth process on the cold surface through experimental literature, the distribution of frost layer on the surface of the finned tube heat exchanger was numerically simulated. The main work and results are as follows:

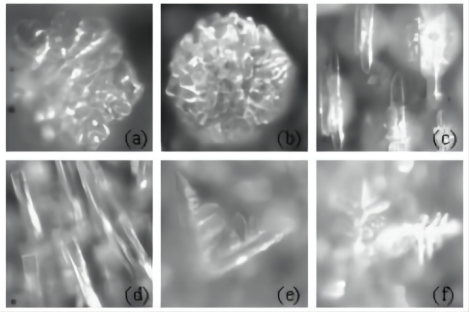

The frosting process on hydrophilic surfaces, bare aluminum surfaces and hydrophobic surfaces in low temperature and high humidity environments was experimentally studied. The experimental conditions are: cold surface temperature -20~-5℃, wet air temperature -5~2℃, relative humidity 85%, wet air flow rate 0.31~0.92 m/s. The results show that: the lower the cold surface temperature, the earlier the condensed water droplets on the bare aluminum surface freeze, the smaller the water droplets when frozen, and the faster the frost crystals grow in the direction perpendicular to the cold surface; the lower the cold surface temperature and the faster the humid air flow rate, the faster the frost layer grows; the hydrophobic surface has the effect of delaying the freezing of condensed water droplets and slowing down the growth rate of the frost layer height, but the delaying effect weakens as the cold surface temperature decreases; for surfaces in frosting/thawing cycles, better drainage effect can effectively reduce the amount of re-frost.

Frost crystal morphology (a) irregular (b) flake (c, d) needle-shaped (e, f) feather-like

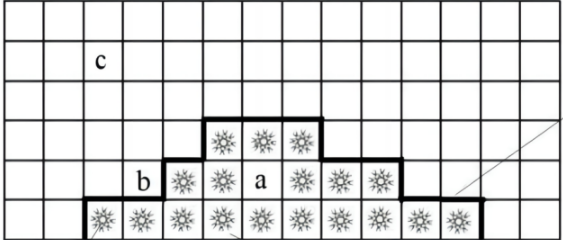

The results of numerical simulation of the frost growth process on the horizontal cold surface show that the average height and density of the frost layer increase with time, the water vapor concentration at the front of the cold surface is high, the phase transfer rate is fast, and the frost density is large; the heat transfer inside the frost layer is mainly conduction, while the heat transfer outside the frost layer is mainly convection, and an inflection point appears in the temperature curve at the frost layer interface.

Schematic diagram of the division of the frost layer growth area on the cold surface

By comprehensively considering multiple factors such as the critical frosting evaporation pressure, the evaporator temperature can be effectively controlled to prevent the evaporator from freezing during humidity testing.

Humidity Freeze Test Chamber

E-mail: market@millennialsolar.com

●Meets: IEC61215-MQT12; IEC61730-MST52

●Has fatigue resistance

●Has moisture penetration resistance

The Humidity Freeze Test Chamber demonstrates its superior performance in solar module testing with its intelligent energy-saving control, precise temperature and humidity regulation, and test methods that meet international standards. This equipment not only ensures the accuracy of the test, but also improves product quality and reduces energy consumption and operating costs. In the future, we will continue to innovate and provide more efficient and reliable environmental testing solutions to help various industries cope with challenges under harsh environmental conditions.