Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Edge Etching Process After Diffusion Junction of Solar Cells

Date : 1 August 2024Views : 1035

Tunneling oxide passivation contact (TOPCon) technology still attracts a lot of attention from photovoltaic industry manufacturers. However, in the production process, the battery will encounter problems with wrap-around plating and edge leakage current. These phenomena will lead to a decrease in the optical and electrical performance of the battery, such as open circuit voltage (Voc), short circuit current density (Jsc) and fill factor (FF). Millennial CLT210 is a leakage current tester designed for RCA process research. It can quickly and automatically measure samples below 230mm, obtain sample edge leakage current information, and help manufacturers improve problems such as wrap-around plating and edge leakage current in the production process.

Diffusion layer and impurity layer formed on the back and edge of silicon wafer after diffusion

After diffusion bonding, a diffusion layer and silicon dioxide layer will be formed on the surface of the silicon wafer (including the front, back and edges). At present, most manufacturers on the market use single-sided diffusion, that is, silicon wafers are placed in pairs with backs attached to backs, but the diffusion impurity gas will still pass through the gaps between the silicon wafers, so impurities will inevitably diffuse into the other side of the silicon wafer.

TOPCon process flow

When making a PN junction on a P-type silicon wafer, the diffused impurity is phosphorus. The P2O5 produced by the decomposition of POCl3 is deposited on the surface around the silicon wafer, forming a mixture of phosphorus atoms, silicon dioxide, and P2O5 - phosphosilicate glass (PSG). When making a PN junction on an N-type silicon wafer, borosilicate glass (BSG) is formed during the diffusion process. The removal process of the two impurity layers is similar.

When solar cells are actually used, the photogenerated carriers generated by light on the front of the cell will flow along the diffusion layer and impurity phosphosilicate glass layer on the edges to the back of the cell, thereby reducing the parallel resistance of the solar cell and causing an electrode short circuit.

Therefore, the diffusion layer and phosphosilicate glass layer PSG on the back and edges of the solar cell must be removed.

Three edge etching process methods

1. Plasma etching

Currently, plasma etching methods are basically only used in laboratories and are no longer used in actual production processes. This method usually removes the residual native oxide or diffused oxide by chemical means first, and then neatly "stacks" the silicon wafers, similar to stacking coins. The stacked silicon wafers are then placed in a plasma chamber. Currently, most use CF4+O2 or SF4+O2 as the reaction gas. The corrosive ion gas generated etches the exposed edges of the stacked silicon wafers, thereby effectively removing the diffused silicon at the edges.

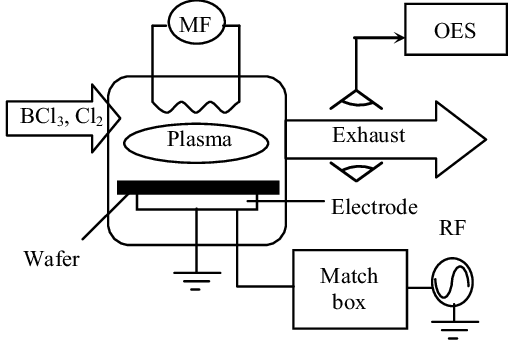

Schematic diagram of plasma etching

The advantages of this method are fast etching rate and isotropy, and the morphology of the silicon wafer will not be changed after etching. However, the etching time needs to be strictly controlled. A shorter etching time will lead to insufficient etching, and impurities at the edge will not be removed cleanly, resulting in a decrease in the parallel resistance of the PN junction or even a short circuit. A longer time will cause excessive damage to the edge of the silicon wafer, thereby damaging the PN junction and forming a high recombination area.

2. Laser edge etching isolation

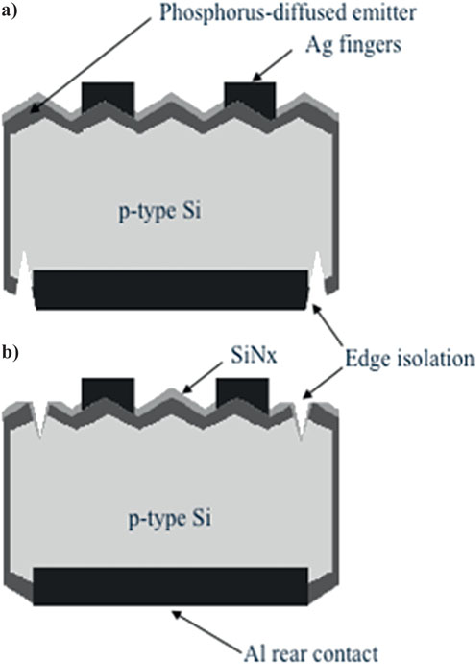

Laser edge etching isolation, also known as laser scribing, uses laser to ablate the front edge of the solar cell to form a closed groove with a certain depth, thereby effectively cutting off the current path to the edge and achieving isolation and insulation between the front electrode and the PN junction on the back of the solar cell. Unlike other processes, laser doping edge isolation is performed after screen printing the paste and sintering.

Laser edge isolation schematic

The laser edge etching isolation process itself cannot improve the conversion efficiency of solar cells, but it can significantly reduce efficiency loss compared with other processes.

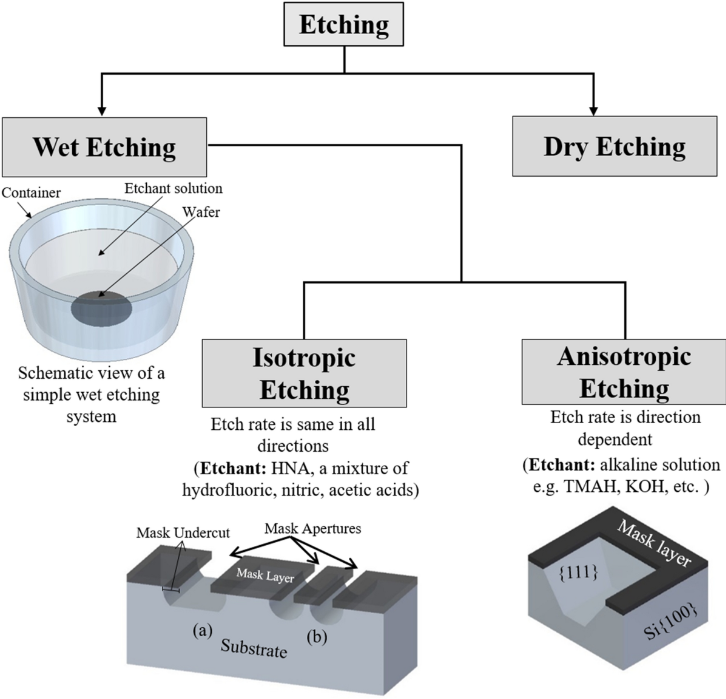

The above two processes are dry etching edge methods, while wet etching removes unnecessary impurities through solution etching.

3. Wet etching

Wet etching of the diffusion layer is to oxidize the back and edge of the silicon wafer with nitric acid to form silicon dioxide. Hydrofluoric acid reacts with silicon dioxide to form a complex hexafluorosilicic acid, while removing the diffusion layer and the phosphorus silicon glass layer PSG. The main reaction formula is as follows:

HNO3+Si→SiO2+NOX↑+H2O

SiO2+4HF→SiF4+2H2O

SiO4+2HF→H2[SiF6]

2NO2+H2O→HNO3+HNO2

Si+4HNO2→SiO2+4NO+2H2O

HNO3+2NO+H2O→3HNO2

During the etching process, it is necessary to ensure that the front side of the solar cell, i.e. the PN junction, is not corroded. Under this requirement, the current silicon wafer roller-carrying liquid etching method is superior to the floating etching method.

Roller-carrying liquid etching process for microcrystalline silicon μc-Si:H film

The roller is used to bring the solution to the back and periphery of the silicon wafer for etching. The silicon wafer is dragged forward by the roller, and the liquid level is lower than the upper surface of the roller. The capillary action on the roller is used to adsorb the silicon wafer, so that the silicon wafer will not deviate from the position and direction when moving in the flowing solution.

The production process is divided into 9 steps: loading silicon wafers → water spraying → edge etching → rinsing → alkali (KOH) cleaning → rinsing → acid (HF) cleaning → rinsing → air knife drying → unloading silicon wafers

Etching process monitoring and detection

After the edge diffusion layer and surface glass layer of the silicon wafer are etched, the appearance surface inspection and conductive type inspection are required.

The appearance surface quality inspection adopts visual inspection and microscope observation. The conductive type can be detected by the rectification method. The metal probe contacts the semiconductor to play a rectifying role and form an asymmetric conductance. For n-type semiconductors, the metal probe points to the semiconductor as the conduction direction; for p-type semiconductors, the semiconductor points to the metal as the conduction direction. By detecting the resistance value around the edges of the silicon wafer, it is determined whether the conduction direction is correct.

Millennial Leakage Current Tester

E-mail: market@millennialsolar.com

Millennial Leakage Current Tester CLT210 can quickly and automatically measure samples below 230mm to obtain leakage current information at the edge of the sample. The probe head is made of gold-plated material to ensure high mechanical precision and long service life. Current test range: 0.1μΩ~110 MΩ can cover most application scenarios and meet the industry's monitoring needs for leakage current in the RCA section. It is the only instrument in the industry that can achieve quantitative and positioning functions for testing leakage current.

·Ultra-wide measurement range: 0.1μΩ~110 MΩ

·Measurement speed: ~1 second/point

·Maximum sample size: 230 mm*230 mm

·High-precision positioning one-button automatic measurement

In short, the current silicon wafer etching technology has been continuously improving. Various process methods have advantages and disadvantages, and are still being continuously improved. Correspondingly, relevant equipment is required to be tested after the process is completed to determine whether the diffusion layer and phosphorus silicon glass layer formed on the back and edge of the silicon wafer after diffusion are completely removed. Millennial CLT210 is a leakage current tester designed for RCA process research to help users strictly control process quality inspection.