Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Study on the Efficiency of Double-sided Textured Perovskite/Crystalline Silicon Tandem Solar Cells

Date : 2 August 2024Views : 930

Perovskite/crystalline silicon tandem solar cells have a rich material stack, each of which has unique functionality. Understanding the optoelectronic properties of these materials is of great significance for improving the efficiency of tandem energy conversion, and is also the key to the development of efficient light collection and light absorption layer technology and cost reduction. Millennial Quantum Efficiency Tester is compatible with all types of photovoltaic cell measurement needs, with a spectral range of up to 300-2500nm, fully locking in the advantages and disadvantages of the cell, helping users optimize structural design, material configuration and process parameters, and improving cell conversion efficiency.

Monolithic perovskite/crystalline silicon two-terminal (2T) tandem solar cells, where wide bandgap perovskite is used as the top cell absorber material and crystalline silicon is used as the bottom cell, have achieved a certified PCE of up to 31.3%, surpassing the PCE record of single-junction silicon solar cells. Currently, most high-efficiency monolithic perovskite/crystalline silicon tandems are based on silicon bottom cells (≈250-300µm thick) with a flat front-side polished or sub-micron textured surface to be compatible with solution-processed perovskite films.

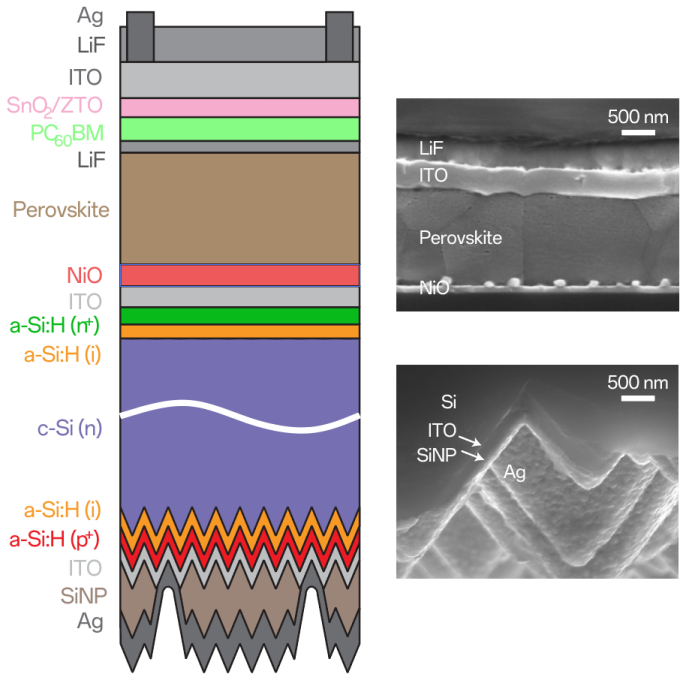

(Left) Schematic diagram of the structure of a perovskite/crystalline silicon tandem solar cell (Right) SEM images of the top and back cross-sections of a perovskite silicon tandem solar cell

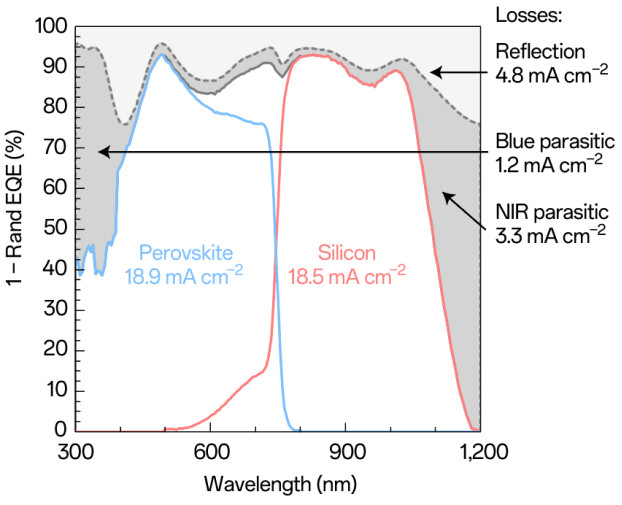

Detailed optical analysis of perovskite/crystalline silicon tandem solar cells. Optical losses mainly come from reflection and parasitic absorption losses. The figure below shows the measured total absorbance, reflectivity and EQE of two subcells in a perovskite/crystalline silicon tandem solar cell.

Measured total absorbance (reflectivity and EQE) of two subcells in a perovskite/silicon tandem solar cell

As shown in the figure, the perovskite top cell and the crystalline silicon bottom cell generate current densities of 18.9mA·cm-2 and 18.5mA·cm-2, respectively. The two main current losses come from front reflection (the area above the total absorbance curve) and parasitic absorption (the area between the total absorbance curve and the EQE curve), reaching 4.8mA·cm-2 and 3.3mA·cm-2, respectively. In order to further improve the current density of the stacked cell, the most direct way is to reduce the reflection on the front surface. Reflection can be reduced by anti-reflection layer, gradient refractive index and velvet light trapping structure.

Drawing on the technical route of crystalline silicon solar cells, the top cell of the perovskite/crystalline silicon stacked solar cell has moved from a planar structure to a pyramid textured surface structure, which can reduce reflection and increase light capture, thereby improving the energy conversion efficiency of the tandem solar cell.

A double-sided textured, production line compatible perovskite/silicon tandem solar cell

The hybrid hole transport layer (HTL) of NiOx/2PACz is obtained by applying an ultra-thin layer of 2PACz on a radio frequency (RF) sputtered NiOx layer. The sputtered dense NiOx layer can avoid the shunt path between the perovskite and the highly conductive TCO layer. At the same time, due to the strong chemical bonding between 2PACz and NiOx, 2PACz can be formed in a uniform conformal manner on the dense NiOx layer, and the surface defects of NiOx are also passivated.

Based on the designed NiOx/2PACz hybrid HTL, a monolithic 2T perovskite/crystalline silicon heterojunction stacked solar cell based on a production line compatible heterojunction bottom cell is fabricated. The TCO layer is located on a double-sided textured n-type crystalline silicon wafer with randomly distributed pyramidal morphology.

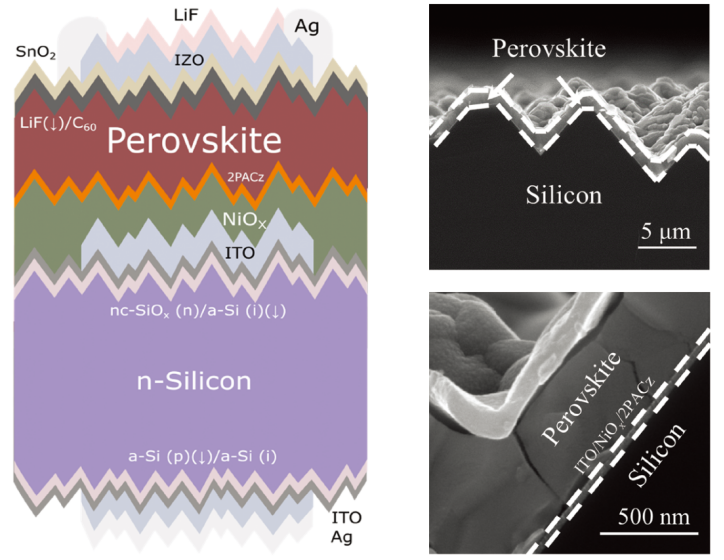

(Left) Schematic diagram of the structure of a double-sided velvet-structured perovskite/crystalline silicon tandem solar cell, (right) SEM image of the anti-reflection layer in the middle of the tandem cell

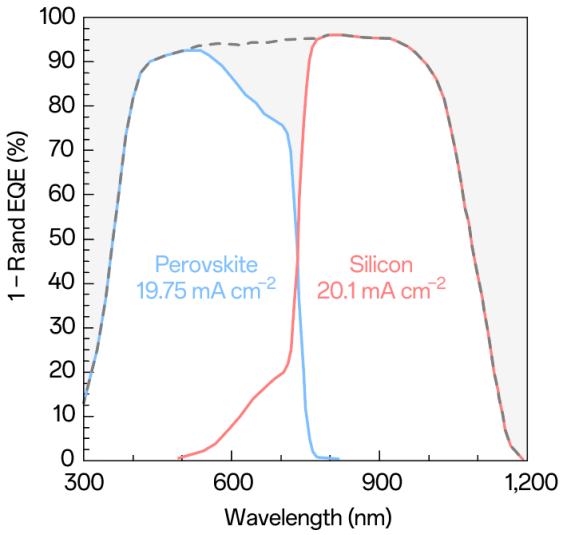

The figure below shows the measured total absorbance, reflectivity and EQE of the two sub-cells in the perovskite/crystalline silicon tandem solar cell made by this technology. The current density of the perovskite top cell and the crystalline silicon bottom cell increased to 19.75mA·cm-2 and 20.1mA·cm-2, respectively.

Measured total absorbance (reflectivity and EQE) of two subcells in a double-sided velvet-structured perovskite/silicon tandem solar cell

The discovery of this new technology also shows that by optimizing the surface morphology, the reflection and light escape of the front surface can be minimized, thereby enhancing the light capture ability and improving the PCE.

Optical light trapping principle of velvet structure

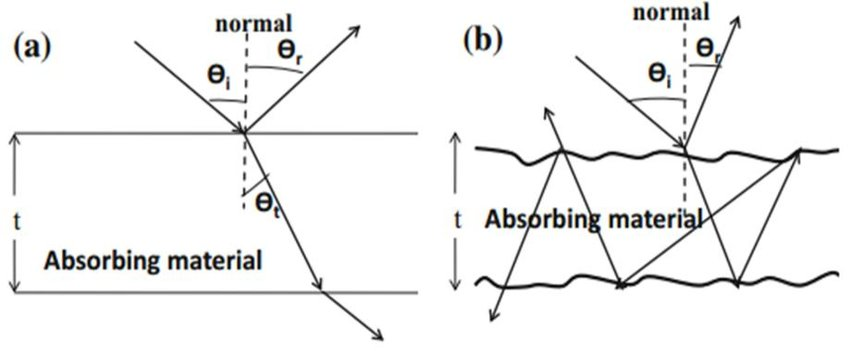

When light is incident on the surface of a material, reflection, refraction and transmission will occur. On a smooth surface, the reflected light and the incident light are on the same plane, and the reflection angle and the incident angle are the same. When the surface is rough, the interaction of light on the surface of the material will change. The change in the direction of adjacent surfaces causes the final reflection angle to be different from the incident angle.

Schematic diagram of reflection, refraction, and transmission of light on a smooth surface (left) and a rough surface (right)

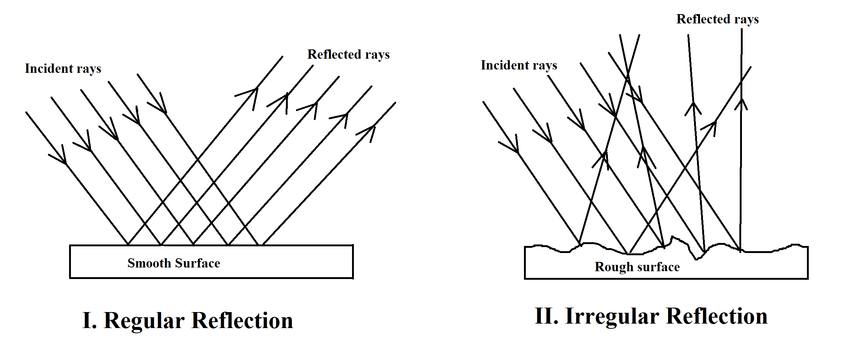

When parallel light falls on a smooth surface, the reflection angle is the same as the incident angle, and this reflection phenomenon is called specular reflection. At this time, the specular reflectivity is measured by placing the detector at the same angle as the incident angle to digitize the reflection phenomenon. When parallel light falls on a rough surface, reflection in random directions occurs, and this reflection is called diffuse reflection.

Schematic diagram of the reflection of parallel light on a smooth surface (left) and a rough surface (right)

Surface roughening not only changes the reflection angle, but also affects the refraction angle, so the propagation distance of light in the absorbing material increases. Surface roughening also helps to adjust the angle of incidence and achieve the condition of total internal reflection, which increases the optical path of the absorbing material.

For solar cells, the total reflectivity is the mirror reflection plus diffuse reflection. In order to measure this reflectivity, an integrating sphere is usually used to measure the reflectivity by collecting light from all directions to integrate and quantify the reflectivity.

Quantum Efficiency Measurement System

E-mail: market@millennialsolar.com

MNPVQE-300 Quantum Efficiency Measurement System can measure the spectral response of all solar cells. The spectral range is from 300nm to 2500nm. It can measure parameters such as EQE, IQE, reflectivity, transmittance and short-circuit current density. It is equipped with a 150mm diameter integrating sphere to make your photovoltaic research progress more smoothly.

● Compatible with all types of solar cells to meet various testing needs

● The spectral range can reach 300-2500nm, and special customization is provided

● Xenon lamp + halogen lamp dual light source structure to ensure light source stability

This article details how to further improve the energy conversion efficiency of perovskite/crystalline silicon tandem solar cells by forming a velvet structure on the front surface to reduce light reflection. Millennial MNPVQE-300 Quantum Efficiency Measurement System is designed to provide data-based guidance for the development of high-performance functional layer optoelectronic materials, helping to maximize the spectral energy utilization of solar cells.