Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Wet Leakage Current Test Under IEC61215 Standard Evaluates Module Insulation Performance

Date : 18 September 2024Views : 5675

As the application scenarios of photovoltaic modules continue to increase, environmental challenges are also increasing. When modules are operated outdoors for a long time, environmental tests such as rain, fog, dew, and snowmelt are inevitable. Therefore, the insulation performance of modules in a humid environment is crucial to their safety and reliability. Wet leakage current test can timely detect potential insulation problems, prevent corrosion and leakage caused by moisture intrusion, and avoid safety accidents. Millennial Wet Leakage Current Tester, through advanced testing methods and strict standards, effectively evaluates the insulation performance of modules in a humid environment.

Standards for wet leakage test

The wet leakage test of photovoltaic modules follows MQT15 in the IEC61215 standard and MST17 in the IEC61730 standard. These standards specify the specific conditions, parameters and methods of the test to ensure the reliability of the test results.

Equipment composition

The equipment consists of an insulating water tank and bracket, a control box, an insulation withstand voltage tester, a control box, a conductivity tester, etc. These devices work together to simulate a humid environment and test the insulation performance of the module.

Method and steps of wet leakage test

Preparation before test:

·An insulating tank or container, which should be large enough to place the module and frame horizontally, and made of insulating material

·The tank must contain a solution of water and additives, with a maximum resistivity of 3500Ω/cm

·Temperature control system: Use a heating and cooling integrated machine to ensure that the experimental water temperature is constant at 22℃±2°C

·The spray equipment is filled with the same solution

·DC power supply and insulation resistance tester

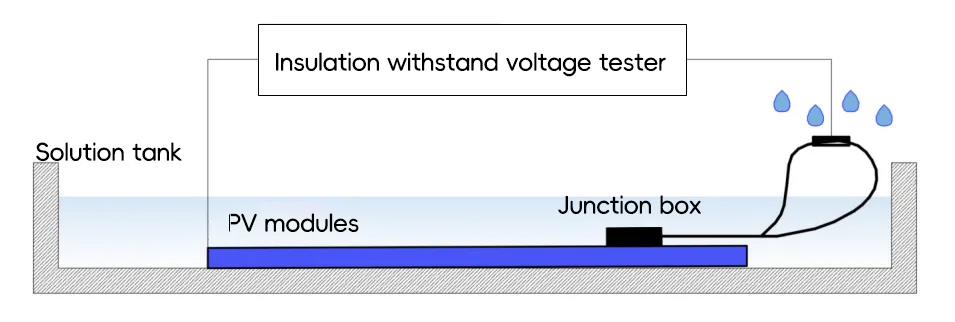

Schematic diagram of wet leakage current test

Test steps:

·Immerse the PV module in the solution. The depth of the solution should be enough to cover all surfaces except the junction box entrance. The cable must be sprayed with the aqueous solution.

·Use a suitable connector to short-circuit the module to be tested and connect it to the positive pole of the tester. Connect the negative output line of the insulation tester to the wire leading out of the water tank.

·Apply voltage to the DC power supply and increase it to 500v or the maximum rated system voltage of the module at a rate not exceeding 500v/s. Keep it for 2min, and then test the insulation resistance.

·Connect the positive pole of the insulation tester to the adapter that short-circuits the module to the frame, wait for 5-10s to release the internal voltage of the module, and the discharge is complete.

IEC 61215 standard requirements:

1. For modules with an area less than 0.1㎡, the insulation resistance shall not be less than 400MΩ

2. For modules with an area greater than 0.1㎡, the test insulation resistance multiplied by the module area shall not be less than 40MΩ·㎡

Importance of wet leakage test

The insulation performance of photovoltaic modules in a humid environment is crucial to their safety and reliability. Wet leakage test can detect potential insulation problems in time, prevent corrosion and leakage caused by moisture intrusion, and avoid safety accidents. In addition, regular wet leakage test can also extend the service life of the module and improve the overall efficiency.

Wet Leakage Current Tester

E-mail: market@millennialsolar.com

Wet Leakage Current Tester ME-PV-WLC tests the insulation performance of the module under wet working conditions, and detects whether moisture from rain, fog, dew or melting snow enters the working part of the internal circuit of the module, causing corrosion, leakage, and non-safety accidents.

·The temperature control system can accurately control the water temperature

·Applicable standards: in accordance with IEC61215-MQT15 clauses and IEC61730-MST17 clauses

·Insulating water tank: PP material, customizable volume, with shelves inside

In summary, the wet leakage test is an important electrical test for photovoltaic modules to evaluate their resistance to moisture intrusion. With the Wet Leakage Current Tester, manufacturers can ensure the quality and reliability of solar photovoltaic modules and provide users with efficient and lasting renewable energy solutions by complying with standards such as IEC 61215.