Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Research on 0BB Busbar-free Technology for IBC Cells

Date : 31 October 2024Views : 3245

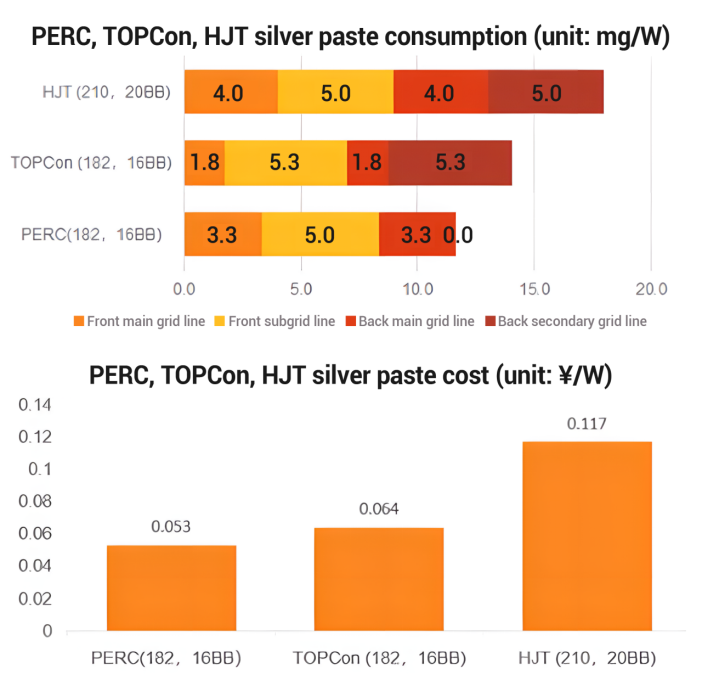

Cost is an important factor restricting the industrial development of high-efficiency N-type solar cells. Among them, the cost of metallization silver paste accounts for the highest proportion of the cost except for silicon materials. With the development of the next generation of n-type high-efficiency cell technology, the consumption of silver paste by solar cells will gradually increase in the future. 0BB busbar-free technology not only reduces the consumption of silver paste, but also reduces the cell interconnection stress, which has obvious advantages in improving module power and reliability.

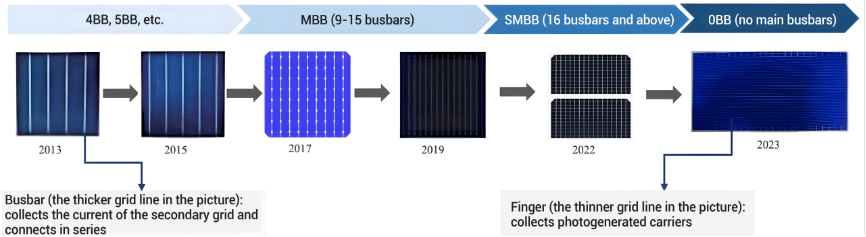

Development of solar cell busbars technology

The electrodes of crystalline silicon solar cells include busbars and fingers. Fingers mainly collect photogenerated carriers, and busbars mainly collect photogenerated current collected by fingers, and at the same time connect with interconnection bars to realize interconnection between solar cells.

Solar cell busbars technology, from the initial 3BB-5BB to the current MBB and SMBB, reduces the silver paste consumption and reduces the front shading loss by increasing the number of busbars and reducing the width of busbars. If silver paste consumption is to be further reduced, 0BB is an effective solution. 0BB technology uses copper welding wire to replace traditional busbars. Copper welding wire realizes current collection and cell interconnection at the same time, which not only saves busbar silver paste, but also realizes copper welding wire base metal replacing busbars for current collection.

The busbar technology of solar cells has developed from MBB and SMBB to 0BB (no busbar)

Advantages of 0BB technology

Cost reduction: It is conducive to thinning silicon wafers to 100μm and reducing silver paste consumption in the cell manufacturing process.

Improve efficiency: reduce the shading area and increase the amount of light absorbed. Shorten the current transmission distance and reduce the series resistance accordingly. At the same time, the design of dense multi-wire increases the contact points between the finger and the wire, improving the ability of photovoltaic modules to resist hidden cracks.

What is 0 busbars IBC technology

In recent years, some Chinese PV module manufacturers have adopted a new PV module structure design, combining 0 busbars technology with IBC cell technology, so that the welding ribbon can be directly connected to the back of the adjacent solar cell, replacing the conventional solar cell front printed busbars, and reducing the shading area of the solar cell front to zero.

There are two main ways to implement 0 busbars technology for IBC PV modules:

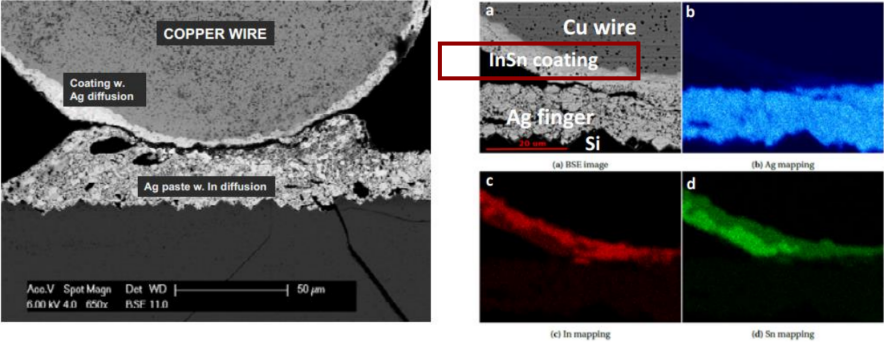

A. 0 busbars coating technology that replaces busbars with copper wire conductive film.

Solder Ribbon - A thin Indium Tin (InSn) coating is used on the copper wire

B. 0 busbars welding dispensing technology that directly replaces busbars with copper wire.

The IBC photovoltaic module packaging process using 0 busbars coating technology is as follows:

a. Wire-film composite: a double-layer composite film (i.e. polyolefin elastomer (POE) + polyethylene terephthalate film (PET)) is composited with copper wire to form a conductive tape.

b. Solar cell welding: The conductive tape is welded to the solar cell through preheating and alignment processes to form a solar cell string.

c. Assemble in the order of "glass-POE+PET-solar cell string-POE-backplane".

d. Circuit connection is formed during lamination.

e. Edge trimming and framing.

However, the above processes have problems such as poor welding, cell bending, elastic deformation, and delamination and cracking.

In response to this, Qinghai Yellow River Upstream Hydropower Development Co., Ltd. from China has developed a packaging process for IBC solar cells using 0 busbars coating technology based on the characteristics of IBC technology. The original double-layer composite film is replaced with a single-layer composite film. The single-layer composite film is polyolefin or ethylene-vinyl acetate copolymer. After melting during the lamination process, it undergoes a cross-linking reaction with the back packaging film to form a stable package. The use of a single-layer composite film in the conductive tape avoids the bending phenomenon and poor welding of IBC solar cells caused by hot pressing.

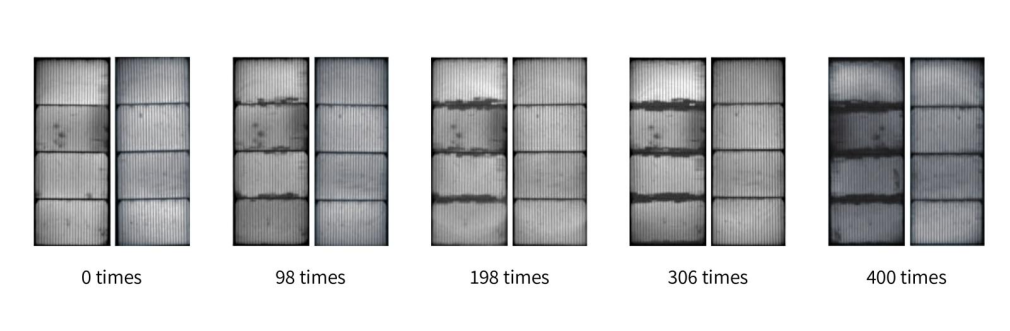

In order to evaluate the stability of 0 busbars IBC photovoltaic modules made by the two processes, aging experiments were mainly carried out through thermal cycling (TC).

Comparison of thermal cycle aging test results

The 0 busbars IBC photovoltaic modules using conventional and improved processes were subjected to thermal cycle (TC) aging tests, and the test was conducted 400 times in total.

The process of a single TC is: the temperature is uniformly reduced from 25℃ to -40℃ within 1h, and then kept warm for 15min; then the temperature is uniformly increased from -40℃ to 85℃ within 3h, and then kept warm for 15min; finally, the temperature is uniformly reduced from 85℃ to 25℃ within 2h. In order to compare the outdoor performance of the two, the EL test of the 0 busbars IBC photovoltaic modules with the two processes was carried out after the TC aging test. The specific EL images are shown below.

EL images of 0 busbars IBC photovoltaic modules using conventional process (left) and improved process (right) after TC aging

Thermal Cycle Test Chamber

Contact us: market@millennialsolar.com

Thermal Cycle Test Chamber can verify and evaluate the reliability of solar cells/modules, and identify manufacturing defects early through thermal fatigue-induced failure modes.

■ Meeting standards: IEC61215-MQT11 (thermal cycle test); IEC61730-MST51 (temperature cycle test)

■ Heating and cooling rate: -40℃~+85℃, linear 0~3.3℃/min adjustable

■ Average power consumption: ≤100 KW·h (TC200 single cycle power consumption)

■ Temperature range: -50℃~+150℃

Through comparative analysis of thermal cycle tests, the advantages of improved processes in improving the reliability and performance of 0 busbars IBC photovoltaic modules have been confirmed, providing useful guidance for the development of packaging technology for photovoltaic modules. The Thermal Cycle Test Chamber can simulate rapid temperature changes, allowing researchers to more accurately evaluate the performance improvement and reliability improvement of 0 busbars IBC photovoltaic modules after improved processes.