Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Towards 27.51% Efficiency, Application of Amorphous/microcrystalline Materials in HBC Solar Cells

Date : 29 November 2024Views : 1080

The solar photovoltaic industry is seeking to improve module performance through innovative manufacturing processes, new materials, solar cell designs and module configurations. SHJ solar cells have advantages such as high PCE, simplified manufacturing processes and low manufacturing temperatures, but have limitations such as low Jsc and high raw material costs. IBC technology is expected to improve the PCE of silicon solar cells. SHJ solar cells use an amorphous silicon layer for effective passivation and form a passivation contact through a doped amorphous silicon layer.

SHJ solar cells and SHJ-IBC solar cells

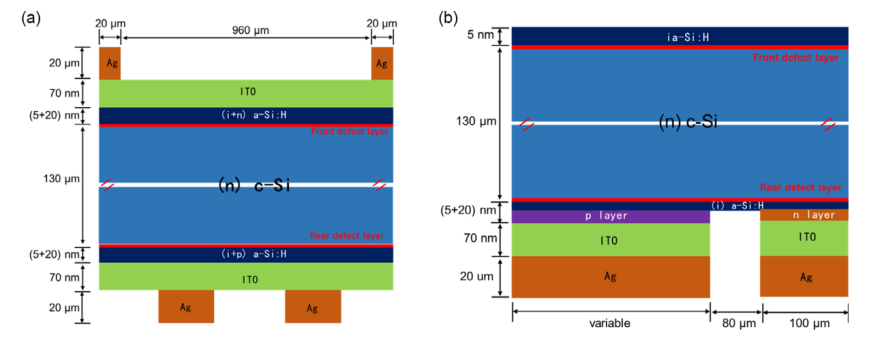

Schematic diagram of the structure of two types of solar cells

SHJ solar cell structure

The structure from top to bottom is: silver/ITO/(n+i) layer/(n) c-Si/(i+p) layer/ITO/silver.

Among them, silver (Ag) is used as the electrode material, and ITO (indium tin oxide) is used as the transparent conductive oxide layer.

The (n+i) layer represents the combination of n-type doped amorphous silicon layer and intrinsic amorphous silicon layer, (n) c-Si represents the n-type doped crystalline silicon layer, and the (i+p) layer represents the combination of intrinsic amorphous silicon layer and p-type doped amorphous silicon layer.

This structure uses the amorphous silicon layer for effective passivation and forms a passivation contact through the doped amorphous silicon layer to improve the efficiency of the cell.

SHJ-IBC Solar Cell Structure

SHJ-IBC solar cells are similar in structure to SHJ solar cells, but with some key differences.

In SHJ-IBC solar cells, both the electron selective contact (ESC) and the hole selective contact (HSC) are located on the back of the cell, which helps reduce the shading of the front surface and improve the utilization of light.

The back of the cell is divided into three regions: ESC, HSC and a gap separating them.

This design aims to reduce efficiency losses due to the electrode shadowing effect while improving the fill factor (FF) and power conversion efficiency (PCE) of the cell.

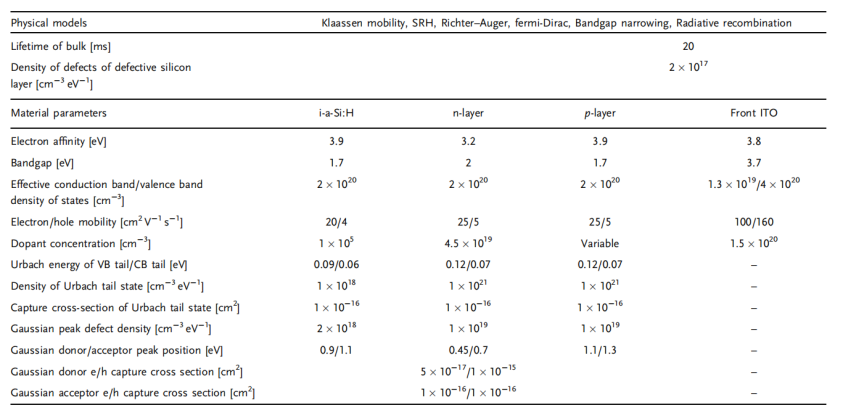

Parameters used in digital twins

These parameters are critical to accurately simulate the performance of SHJ solar cells because they affect carrier transport, recombination, and the overall efficiency of the cell. By precisely setting these parameters, researchers can create a digital twin that accurately reflects actual cell performance and can then evaluate and optimize cell design.

Contact Resistance Simulation

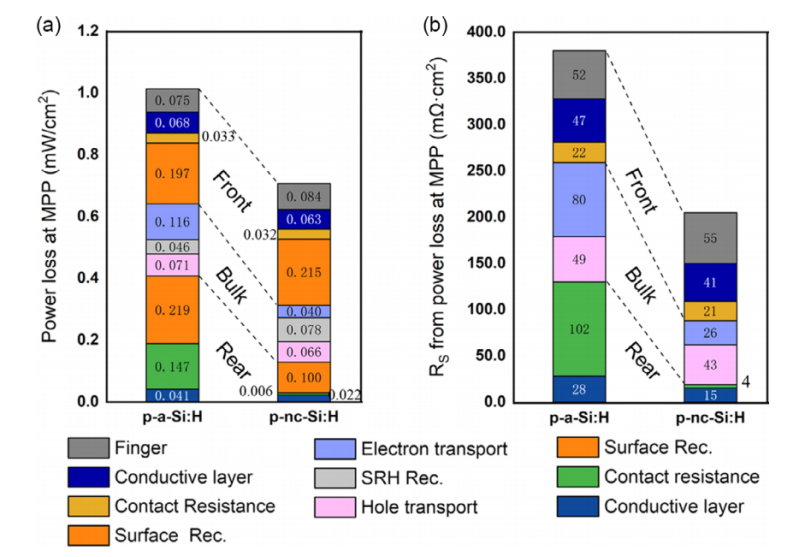

Evaluation of power losses at maximum power point (MPP) for SHJ solar cells with amorphous silicon (p-a-Si:H) and nanocrystalline silicon (p-nc-Si:H) hole selective contact (HSC) layers.

Analysis of power loss and series resistance of SHJ solar cells at maximum power point (MPP)

Power loss analysis:

The power loss at the maximum power point of SHJ solar cells with p - a - Si:H hole selective contact (HSC) layer and p - nc - Si:H HSC layer was compared, indicating that the cell performance enhancement mainly originated from the back side HSC layer.

The series resistor consists of:

Decompose Rs into multiple components, including the intrinsic components inside the bulk phase, the carrier transport resistance of the front and rear surface transparent conductive oxide (TCO) and electrode finger regions, and the contact resistivity of the electron selective contact (ESC) and HSC (ρESC and ρHSC).

It can be seen from the figure that ρESC decreases slightly but does not change much, while ρHSC decreases significantly from 102 to 4mΩ cm², which shows that reducing the contact resistivity of the HSC layer is of great significance in improving battery performance.

SHJ solar cell contact resistivity (ρC) simulation

Schematic of the TLM simulation structure: This structure consists of two identical contact stacks, each 1000 microns wide, on a c-Si substrate and separated by a variable gap.

J-V characteristic curve: J-V (current-voltage) characteristic curve for the evaluation of electron selective contact (ESC) at different contact pad spacings under dark conditions (voltage range -0.2 to 0.2 volts). These curves are used to calculate the contact resistivity ρC.

Total resistance RT of different contact pad spacing: Total resistance RT of ESC at different contact pad spacing. These data are used to calculate the contact resistivity ρC by the TLM method.

Calculation of contact resistivity ρC: The contact resistivity ρC can be calculated from the figure using the formula ρC = RC - LT / W, where RC is half the contact resistance, LT is half the effective transfer length, and W is the default contact in TLM simulations length (1 micron).

Effect of doping concentration on contact resistivity: Doping concentration of the p-layer determined by TLM simulation, with the points of p-a-Si:H HSC and p-nc-Si:H HSC highlighted. By increasing the doping concentration, ρHSC can be significantly reduced.

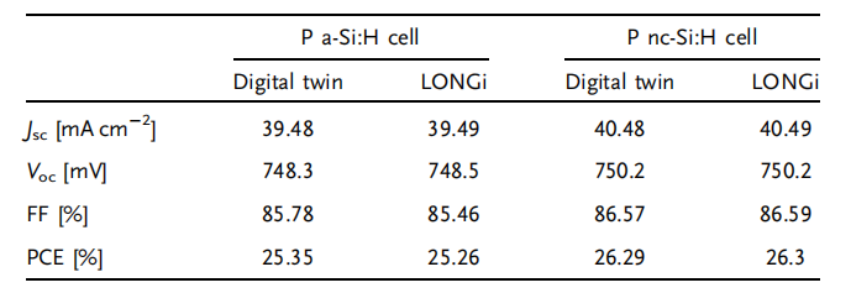

Comparison of electrical performance of SHJ solar cell digital twins

Short-circuit current (Jsc): The Jsc of the solar cell using p-nc-Si:H HSC is slightly higher than that of the cell using p-a-Si:H HSC, which indicates that the nanocrystalline silicon layer can improve the short-circuit current of the cell.

Open-circuit voltage (Voc): The Voc of the solar cell using p-nc-Si:H HSC is also slightly higher than that of the cell using p-a-Si:H HSC, which may be due to the better carrier selectivity of the nanocrystalline silicon layer, which reduces the recombination loss of carriers.

Fill factor (FF): The FF of the solar cell using p-nc-Si:H HSC is also slightly higher than that of the cell using p-a-Si:H HSC, which indicates that the nanocrystalline silicon layer can improve the overall performance of the cell.

Power conversion efficiency (PCE): The PCE of the solar cell using p-nc-Si:H HSC is higher than that of the cell using p-a-Si:H HSC, which is consistent with the improvement of Jsc, Voc and FF.

Comparison with LONGi solar cell: The simulation results of the digital twin are very close to the experimental results of LONGi, which verifies the accuracy and reliability of the digital twin model.

SHJ solar cells using nanocrystalline silicon (p-nc-Si:H) as the HSC layer have superior electrical performance to those using amorphous silicon (p-a-Si:H).

Creation of digital twins of SHJ and SHJ-IBC solar cells

Electrical performance of SHJ-IBC solar cells

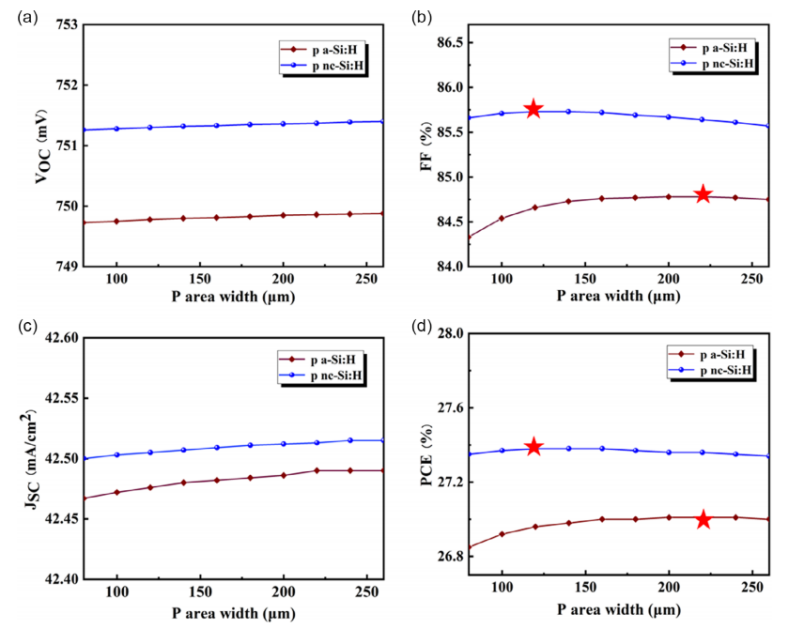

Relationship between HSC width and VOC:

As the width of HSC increases, the open circuit voltage (VOC) increases. Cells using p-nc-Si:H HSCs exhibit higher VOC than cells using p-a-Si:H HSCs, which is attributed to the higher doping concentration of p-nc-Si:H, resulting in stronger band bending in c-Si and reduced recombination losses.

Relationship between HSC width and FF:

The fill factor (FF) increases with the width of HSC.

Cells using p-nc-Si:H HSCs exhibit higher FF than cells using p-a-Si:H HSCs due to their higher carrier collection capabilities.

Relationship between HSC width and JSC:

Short-circuit current (JSC) increases with increasing HSC width.

Reduced recombination losses and enhanced carrier collection capabilities help improve JSC.

Relationship between HSC width and PCE:

Power conversion efficiency (PCE) increases with increasing HSC width, but there is an optimal point beyond which the efficiency begins to decline.

For SHJ-IBC cells using p-a-Si:H HSC, the PCE reaches 27.01% when the HSC width is 220 μm. For SHJ-IBC cells using p-nc-Si:H HSC, the PCE reaches 27.38% when the HSC width is 120 μm.

When reducing the gap width from 80 μm to 20 μm, the PCE of the cell with p-nc-Si:H HSC can be further improved to 27.51%.

Short Circuit Current (JSC): JSC for all three cases was close to 42.5 mA cm^-2, indicating that the photogenerated current density remained consistent across designs.

Open Circuit Voltage (VOC): Cells using nanocrystalline silicon (nc-Si:H) HSCs exhibited higher VOC than cells using amorphous silicon (a-Si:H) HSCs. Reducing the gap width from 80 μm to 20 μm further slightly improved the VOC of cells using nc-Si:H HSCs.

Fill Factor (FF): Cells using nc-Si:H HSCs exhibited higher FF than cells using a-Si:H HSCs.

Reducing the gap width further improved the FF of cells using nc-Si:H HSCs.

Power Conversion Efficiency (PCE):

The PCE of cells using a-Si:H HSCs was 27.01%.

The PCE of cells using nc-Si:H HSCs was 27.38%.

Reducing the gap width from 80 μm to 20 μm increases the PCE of the cell using nc-Si:H HSC to 27.51%.

By creating a digital twin model of high-efficiency silicon heterojunction (SHJ) solar cells, the actual efficiency limit of SHJ-IBC solar cells was evaluated. The efficiency of SHJ-IBC cells using amorphous HSCs can reach 27.01% and 27.38% when using nanocrystalline HSCs. Reducing the gap width from 80 μm to 20 μm can increase the efficiency to 27.51%.

Millennial Raman Spectrometer

E-mail: market@millennialsolar.com

Raman Spectrometer has excellent UV sensitivity and excellent spectral repeatability. It uses 325 laser and optimizes the UV optical path design to improve spectral stability. It efficiently uses 325 laser and sample Raman signals to achieve in-situ testing of amorphous/microcrystalline materials above 5nm, and is the best choice for characterizing "microcrystalline-heterojunction" batteries.

·Industry best, signal counts of UV-sensitive silicon first-order peak better than 1000 (1 second integration time)

·Spectral repeatability: ≤520±0.02cm-1 after single crystal silicon calibration

·Grating line count: ≤2400 gr/mm; ≤1800 gr/mm

As the key role of amorphous/microcrystalline materials in HBC solar cells becomes increasingly prominent, Raman Spectrometer has become an indispensable tool in this field with its excellent UV sensitivity and spectral repeatability. The 325nm laser and optimized UV optical path design adopted by the tester not only improve the spectral stability, but also realize the in-situ testing of amorphous/microcrystalline materials above 5nm, providing strong technical support for the characterization of "microcrystalline-heterojunction" cells.