Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Research on the sealing loss control method in the manufacturing process of photovoltaic modules

Date : 30 July 2025Views : 1175

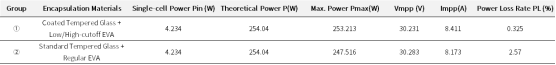

“Low cost, high efficiency and long life” is the pursuit of PV module manufacturing, and controlling and reducing module power loss is the key.

The power loss of PV modules mainly includes two parts: encapsulation loss and operation loss. Encapsulation loss refers to the power loss caused by material characteristics and process problems during the manufacturing process of the module, which is usually expressed in terms of the power conversion rate (CTM) or power loss rate (PL). Ideally, the output power of a module should be equal to the sum of the power of all cells, but the actual power is often lower than the theoretical value, and the CTM value is usually between 96% and 97%.

Module Design Principles

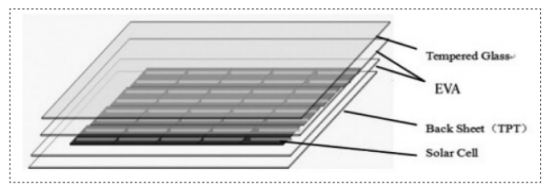

Module encapsulation structure diagram

Typical layered structure of crystalline silicon photovoltaic module, including tempered glass, EVA adhesive film, battery string (cell, interconnecting strip, converging strip), EVA adhesive film, backsheet, etc. from top to bottom.

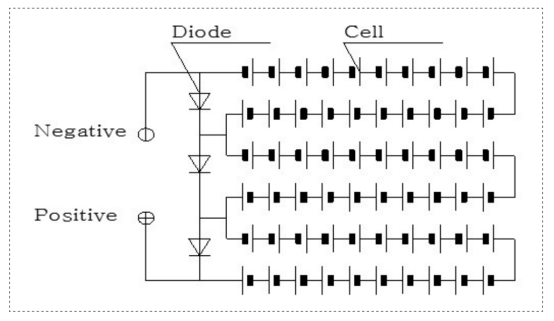

Component electrical schematic

Through the diode and battery positive and negative connection schematic, explain the series path of current in the module and the principle of electrical work, and provide theoretical basis for the analysis of electrical loss (such as series resistance, mismatch loss).

Optical loss analysis and control methods

1.Gaining effect of encapsulation material on optics

The optical loss of PV module mainly originates from the absorption and reflection of incident light by encapsulation material. Research shows that ultra-white embossed tempered glass can improve the transmission rate of light in the wavelength range of 300~1200nm due to its low iron content and surface embossed structure, which improves the short-circuit current of the encapsulated module by 3~4%.

2. Application of Improved Encapsulation Materials

Coated Glass: Adding nano-SiO₂ reflection-reducing film on the surface of ordinary PV glass, the light transmittance is increased from 91.5% to 94%, and the power output of the module is increased by 1.5~2%.

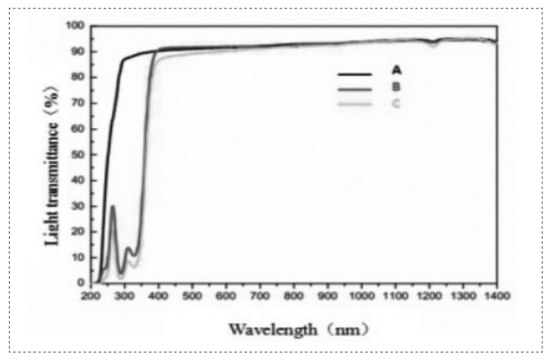

Different EVA transmittance

EVA film optimization: Low cut-off EVA (cut-off wavelength 280nm) can better utilize the light energy in the 280~380nm band than high cut-off EVA (380nm), which can enhance the module power by about 0.8% when used with high square resistance cells.

Backsheet material: High reflectivity white backsheet can reflect up to 80% of the light above 500nm, which improves efficiency by 1~2% compared with black or transparent backsheets.

Electrical loss analysis and control methods

1. Main sources of electrical loss

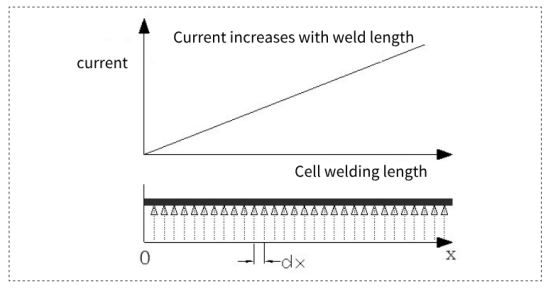

Interconnecting strip welding section current schematic

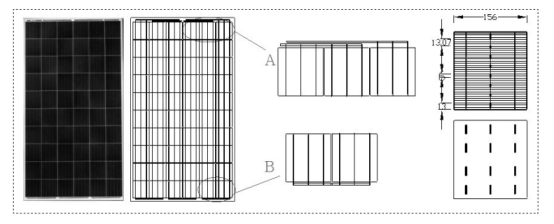

Example of polycrystalline module connected with cell and converging strip schematic diagram

Electrical losses mainly include battery mismatch loss, interconnection strip resistance loss, busbar resistance loss and junction box resistance loss. Research shows that:

Interconnection strip resistance loss accounts for the largest proportion, more than 60%;

Battery mismatch loss and sink band resistance loss each account for about 15%;

Junction box and contact resistance loss accounts for less than 1%.

2. Key measures to reduce electrical losses

Optimized interconnect strip design: Through front-side silver plating and calendered longitudinal structure, part of the light can be reflected back to the module, and the power can be increased by nearly 2%.

Improve battery staging process: Dual staging method of power and current is adopted to reduce battery series mismatch.

Reducing the resistance of the converging strip: Optimizing the material and welding process of the converging strip to reduce the current transmission loss.

Power attenuation and control during operation

The power attenuation of PV modules during operation is divided into initial photoluminescence attenuation (LID) and aging attenuation:

Initial photoluminescence attenuation: It is mainly caused by the boron-oxygen complex in P-type crystalline silicon, which can be mitigated by pre-lighting treatment.

Aging attenuation: related to the degradation of encapsulation materials, the use of UV-resistant materials can slow down the rate of attenuation.