Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Identification and Treatment of Hot Spot Phenomena in Photovoltaic Power Station Components

Date : 8 August 2025Views : 1445

Overview of Hot Spot Phenomena

Mechanism of Hot Spot Formation: Hot spots are phenomena caused by abnormal temperature rises in localized areas of photovoltaic components, usually triggered by shading, pollutant deposits, manufacturing defects (such as poor welding or microcracks in the cells), or current mismatches. The abnormal areas cannot generate power normally and instead become loads, causing temperatures to rise sharply and creating a vicious cycle.

Types and characteristics of hot spots

Transient hot spots: Regular high-temperature areas with clear boundaries, accompanied by a sudden drop in power generation.

Contamination-type hot spots: Irregular block-shaped temperature anomalies that gradually worsen as contaminants accumulate.

Internal defect hot spots: Small in area but with significant temperature rise, such as poor welding or cell cracks.

Current mismatch hot spots: Dynamic changes, with temperature distribution changing periodically according to operating conditions.

The impact of hot spots: Hot spots accelerate material aging, reduce photovoltaic conversion efficiency, and in severe cases can cause permanent damage to components, threatening the operational safety of power plants.

Hot spot identification technology

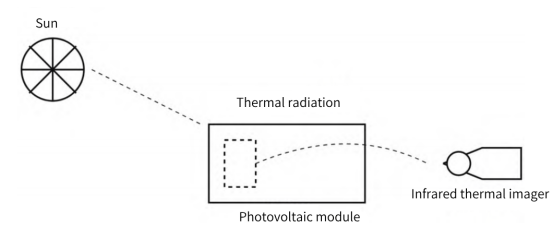

Schematic diagram of infrared thermal imaging measurement principle

Infrared thermal imaging technology: Based on the relationship between the surface temperature of an object and its radiation characteristics, infrared detectors capture temperature distributions and combine environmental parameter compensation mechanisms to improve measurement accuracy.

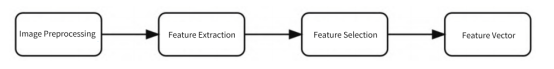

Heat Spot Feature Extraction Flowchart

Feature extraction method: Use grayscale co-occurrence matrices, optical flow equations, etc. to extract the texture and dynamic evolution characteristics of heat spots, and construct multi-dimensional feature vectors (such as maximum temperature, average temperature, shape factor, etc.).

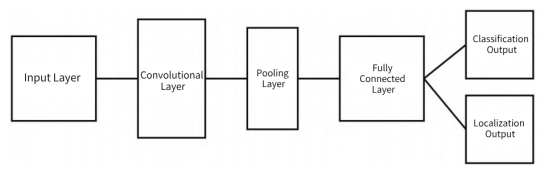

Deep Learning Model Architecture for Hotspot Detection

Input Layer: Infrared thermal images.

Feature Extraction Layer: Convolution layers, pooling layers (possibly incorporating attention mechanisms).

Output Layer: Dual-task output for classification (hotspot type) and localization (bounding box regression).

Deep Learning Model: Utilizes an improved convolutional neural network combined with transfer learning and attention mechanisms to achieve precise classification and localization of hotspots, with an identification accuracy rate exceeding 95%.

Hot Spot Treatment Technology

Tiered Treatment Plan:

Mild hot spots (temperature anomaly < 20°C): Surface cleaning to remove contaminants.

Moderate hot spots (20–40°C): Replace bypass diodes or repair local defects.

Severe hot spots (> 40°C): Replace the entire module after assessment.

Process Flow: Includes safety procedures (e.g., power disconnection, discharge), robotic cleaning, diode replacement, local repairs, etc., to ensure processing quality and traceability.

Hot Spot Treatment Effect Evaluation System

Effect Evaluation: Evaluated from three dimensions—short-term performance, environmental adaptability, and long-term reliability—data shows that the power generation efficiency of treated components has increased by 5% to 12%, with a payback period of 1 to 2 years.

Using infrared thermal imaging technology and deep learning algorithms, the system achieves intelligent identification and precise localization of hot spots. Based on a tiered treatment plan (such as cleaning, localized repairs, or component replacement), it significantly improves the performance recovery rate of components (with power generation efficiency increasing by 8% to 12%). The established evaluation system validates the effectiveness of the treatment technology, providing a scientific basis for the operation and maintenance of photovoltaic power plants.

Millennial Hot Spot Durability Tester

email:market@millennialsolar.com

The Millennial Hot Spot Durability Tester is a precision testing device specifically designed for photovoltaic modules. This device complies with the hot spot durability testing requirements specified in the IEC 61215 standard (MQT19). It accurately detects hot spot effects caused by foreign object obstruction, internal cell defects, or manufacturing defects in photovoltaic modules. It is used for evaluating the hot spot durability of solar cell modules under localized abnormal operating conditions, thereby assisting manufacturers in optimizing module design and enhancing product reliability and safety.