Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Post-Etching Passivation Technology (PET) for Metallisations: Reducing Silicon Solar Cell Cutting Losses and Enhancing Module Efficiency

Date : 28 September 2025Views : 1130

The cutting process of silicon-based solar cells (e.g., shingled or half-cell modules) exposes highly reactive cut edges, inducing carrier recombination and reducing power-free-from-failure (pFF). Traditional solutions require modifying pre-metallization processes, which exhibit low industrial compatibility and high costs. This paper proposes a post-metallization edge passivation technology (PET) that achieves efficient edge passivation through precise control of AlOₓ film thickness (7/14 nm) via thermal atomic layer deposition (ALD) combined with low-temperature annealing. This technology integrates Millennial online film thickness tester for real-time monitoring, ensuring consistent passivation layer thickness to optimize long-term stability. Ultimately, it enables double-sided PERC shingled cells to achieve a high power density output of 23.5 mW/cm².

PET Technology and Cell Characterization

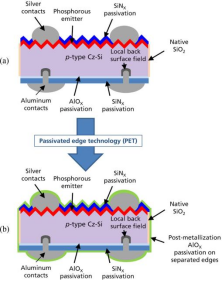

(a): Cross-section schematic of double-sided pSPEER solar cell (b): Cross-section of cell after PET treatment

pSPEER® Technology Principle

Edge Passivation Mechanism: Native SiO₂ at cut edges → Full Al₂O₃ encapsulation (7/14 nm) inhibits recombination

ALD Process Advantages:

Conformal deposition → Three-dimensional edge coverage

High negative fixed charge density (~10¹³ cm⁻²) → Field-effect carrier repulsion

Light transmittance >98% (d<15 nm, OPTOS optical simulation)

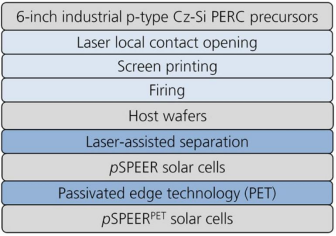

Battery Preparation Process

pSPEER® Battery Preparation Process Flow

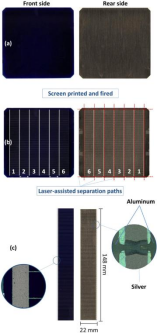

(a) Industrial 6-inch PERC precursor; (b) Metallized wafer capable of separating 6 cells; (c) Laser-separated cells (22×148 mm)

Substrate: Industrial 6-inch Ga-doped p-type Cz-Si PERC precursor.

Metallization: Screen-printing silver main grid, aluminum backfield, and front silver grid; rapid sintering.

Cutting: TLS (laser thermal cracking) or LSMC (laser scribing + mechanical cracking)

PET Processing: ALD deposition of AlOₓ → Hot plate annealing

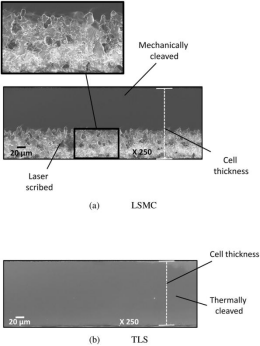

(a) LSMC separation edge (1/3 area rough); (b) TLS separation edge (entirely smooth)

Edge Passivation Experiment

Experimental Workflow for PET's Impact on Separated Cells

Experimental Design:

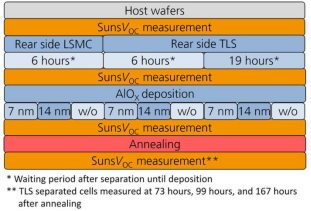

Procedure: SunsVOC measurement (host wafer → dicing state → deposition state → annealing state).

Control group: No AlOₓ coating, annealing only.

SunsVOC and IV characteristic characterization

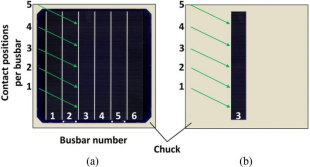

(a) SunsVOC measurement contact point on the wafer; (b) Measurement at the same location on the separated cell

Evaluate the impact of separation and passivation processes on cell performance via SunsVOC measurements. Measurements conducted under 1000 W/m² illumination, focusing on pFF and open-circuit voltage (VOC) variations. Measurements taken at identical locations before and after separation to eliminate local inhomogeneities. IV testing performed on both front and back sides under standard conditions, considering specified area current density in busbar-free regions.

PET Experimental Protocol

Compare the effects of LSMC and TLS separation processes on pFF. Deposit AlOₓ (7 nm or 14 nm thickness) 6 hours or 19 hours after TLS separation to investigate the impact of dwell time on passivation effectiveness. Set annealing temperature to <225°C. Measure minority carrier lifetime τeff via QSSPC.

Passivation Layer Performance Validation

Schematic of Cell Stacking During AlOₓ Deposition Process

AlOₓ Deposition Process

Separated cells (LSMC/TLS process) exposed to air for 6–19 hours, forming native SiO₂ during exposure;

Reactor loading: Cells placed face-up with height spacers between them;

Thickness verification: Real-time thickness monitoring via in-line film thickness gauge, targeting d1=7 nm and d2=14 nm.

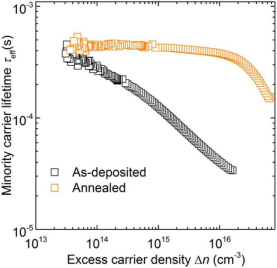

Carrier Lifetime After AlOₓ Deposition/Annealing

Following AlOₓ annealing, τeff=432 μs (Δn=10¹⁵ cm⁻³), corresponding to Seff=22 cm/s, indicating the current process achieves low edge recombination rates.

SunsVOC Results

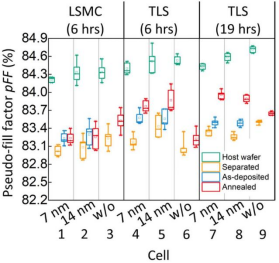

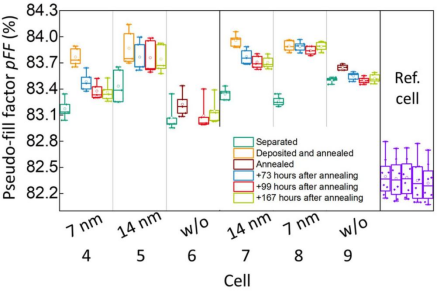

pFF Changes Measured by SunsVOC

PET Effect: Both LSMC and TLS separation resulted in a pFF decrease of −1.2%.

After AlOₓ deposition,

the TLS-separated cell showed a pFF increase of +0.4%, further rising to +0.7% after annealing;

the LSMC-separated cell only improved by +0.3%.

Stability of pFF after PET (14 nm AlOₓ with no decay)

Stability: The 14 nm AlOₓ passivation layer exhibits long-term stability (pFF stable for 167 hours), likely due to the growth of a dense oxide layer.

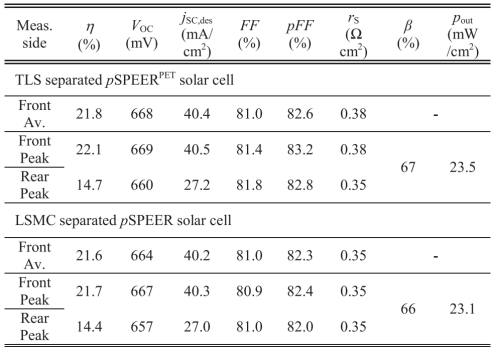

IV Test Performance

Comparison of IV Performance Between TLS+PET and LSMC Cells

Optimal TLS+PET Cell: Front-side efficiency ηf = 22.1%, output power density pout = 23.5 mW/cm² (including 10% back-side irradiation).

Compared to LSMC unpassivated cells: Δpout = +0.4 mW/cm².

The proposed post-metallization passivated edge technology (PET) effectively suppresses edge recombination in shingled solar cells through low-temperature ALD deposition of aluminum oxide followed by annealing. Combining TLS separation with PET processing increases pFF by +0.7%, achieving cell efficiency of 22.1% and power density of 23.5 mW/cm². The 14 nm AlOₓ passivation layer demonstrates long-term stability. The PET technology requires no modification to pre-treatment processes, making it suitable for industrial production and providing a viable solution for enhancing the efficiency of small-sized solar cells.

Millennial Online Film Thickness Tester

email:market@millennialsolar.com

The POLY5000 is an online film thickness tester specifically designed for photovoltaic process monitoring. It performs rapid, automated 5-point simultaneous scanning of samples to monitor the thickness and optical constants of various films on industrial production lines. It delivers fast and accurate measurements of film thickness, optical constants, and other parameters, with customizable measurement dimensions based on customer sample sizes.

✔ Film thickness measurement range: 20nm–2000nm

✔ Rapid, automated 5-point simultaneous scanning

✔ Non-contact, non-destructive measurement with zero breakage rate

✔ 24/7 automated, non-stop calibration to ensure production efficiency

The Millennial Online Film Thickness Tester empowers users to optimize film thickness characteristics by enabling real-time monitoring of AlOₓ layer thickness during deposition and verifying thickness's impact on stability.

Related Products