Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Principles of EL Testing for Solar Panels

Date : 17 October 2025Views : 665

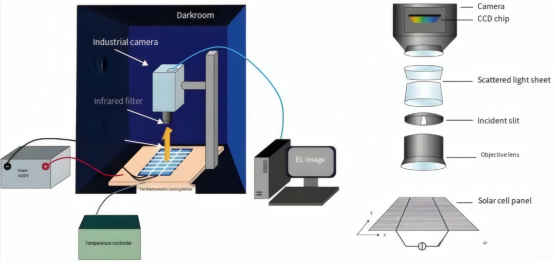

The principle of EL testing involves applying a forward current to solar panels, causing them to actively emit light like light-emitting diodes (LEDs). An infrared camera captures the emitted near-infrared light, enabling diagnosis of internal defects and performance inhomogeneities based on the distribution of light intensity.

I. Step-by-Step Analysis of EL Testing Mechanism

EL Testing Mechanism

1. Theoretical Basis: Reversibility of the Photoelectric Effect in Semiconductor PN Junctions

Photovoltaic Effect (Forward): The core of a solar cell is a PN junction. Under illumination, photons excite electron-hole pairs, which separate under the built-in electric field to generate current and voltage—converting light energy into electrical energy.

Electroluminescence Effect (Reverse): This process is reversible. When a forward bias is applied to the solar cell's PN junction (i.e., connecting the positive terminal to the cell's positive electrode and the negative terminal to the cell's negative electrode), it injects non-equilibrium charge carriers (electrons and holes). As these carriers recombine near the PN junction, they release energy in the form of photons—the process of converting electrical energy into light energy. This constitutes the physical foundation of EL testing.

2. Key Components and Workflow

DC Power Supply: Provides an adjustable forward bias current to the entire module. The current magnitude typically ranges between 5%–20% of the module's short-circuit current (Isc).

Darkroom Environment: Testing must be conducted in complete darkness, as the light emitted by solar cells is extremely faint (primarily near-infrared) and any ambient light will interfere with imaging.

Infrared Camera: The system's “eyes.” The light emitted by standard silicon-based solar cells during electroluminescence primarily occurs around 1150nm (near-infrared spectrum), invisible to the human eye. Therefore, specialized cameras sensitive to near-infrared light are required (typically silicon-based CCD or InGaAs cameras, with the latter being more sensitive to longer wavelengths).

Computer and Control Software: Controls power output, camera exposure time, and acquires, processes, and displays EL images.

II. EL Testing Workflow:

Component Placement: Place the solar panel under test into the dark box and correctly connect its positive and negative terminals to the DC power supply.

Current Application: Turn off the light source. The software controls the power supply to inject a specified forward DC current into the module.

Image Acquisition: The infrared camera captures images of the illuminated module. Exposure time typically ranges from several hundred milliseconds to several seconds, depending on the current magnitude and camera sensitivity.

Image Analysis: The computer acquires grayscale images (EL images). Technicians assess the module's intrinsic quality based on the image's brightness contrast.

III. How to Interpret EL Images?

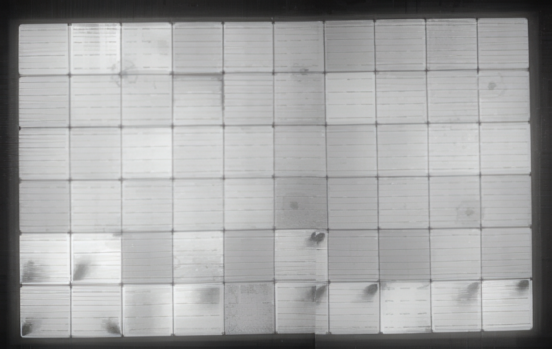

In EL images, brightness directly reflects the intensity of carrier recombination luminescence in that area, thereby indicating the current generation capability and quality of the solar cell in that region.

Common Defect Images in Module EL Testing

Bright, uniform areas: Indicate good performance in that region. Current flows smoothly, with strong carrier recombination luminescence.

Dim or black areas: Indicate defects in that region, resulting in weak or absent carrier recombination luminescence. Causes include:

Cracks: Hidden cracks, broken grids, etc. Cracks block current pathways, preventing current flow and luminescence behind the crack, appearing as distinct black lines in the image.

Breakage: Fragmentation of the cell, operating on the same principle as cracks.

Printing/Burning Defects: Improper grid line printing or sintering, resulting in excessively high series resistance or localized short circuits.

Material Defects: Such as dislocations or impurities. These defects act as carrier recombination centers, causing carriers to dissipate energy through “non-radiative recombination” (heat generation) at the defect site before luminescent recombination occurs. Consequently, this area exhibits reduced light emission.

Low-Efficiency Cells or Mixed Batches: Cells with differing efficiencies emit varying intensities under the same current; lower-efficiency cells appear dimmer.

Black Core: Darkening in the central region of the cell, typically associated with silicon ingot resistivity variations or texturing issues.

Black Edge: Darkening along the cell edges, usually caused by insufficient edge etching or contamination reducing parallel resistance, resulting in edge leakage.

Related Products