Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Enhancing Environmental Stability and Efficiency of Perovskite Solar Cells: A Strategy Based on Sb³⁺/S²⁻ Alloyed FAPbI₃

Date : 6 February 2026Views : 50

Perovskite solar cells (PSCs) have garnered significant attention due to their exceptional photovoltaic conversion efficiency. However, most high-efficiency PSCs still require fabrication under inert atmospheres (e.g., nitrogen-filled glove boxes), which to some extent limits their large-scale commercial production. Developing highly efficient and stable PSCs under ambient conditions via a two-step process is crucial for advancing their industrial application. The Millennial Temperature and Humidity Combined Environmental Test Chamber is specifically designed to validate and evaluate the reliability of modules or materials. It achieves rapid temperature cycling, enhances testing efficiency, and complies with standards such as IEC 61215.

This paper proposes a novel component engineering strategy. Through a sequential process in ambient air, trivalent antimony (Sb³⁺) and divalent sulfur (S²⁻) ions are simultaneously alloyed into the lead formamide iodide (FAPbI₃) lattice. This significantly enhances the material's intrinsic stability and battery performance.

Research Methods and Material Preparation

Perovskite films were prepared under ambient air conditions using a sequential deposition method. First, a solution of SbCl₃-thiourea (Sb-TU) complex was spin-coated onto a PbI₂ substrate at 150°C. Subsequently, a solution of formamidine iodide (FAI) was introduced to complete the conversion reaction, forming FAPbI₃ films with Sb³⁺/S²⁻ alloying. By systematically varying the Sb-TU loading (0–2.0 mol%), the crystal structure and optoelectronic properties of the material were optimized.

Alloying Effect and Mechanism Analysis

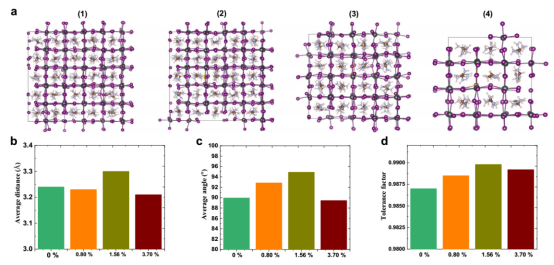

First-Principles Molecular Dynamics (AIMD) Simulations of Sb³⁺/S²⁻ Alloying in FAPbI₃

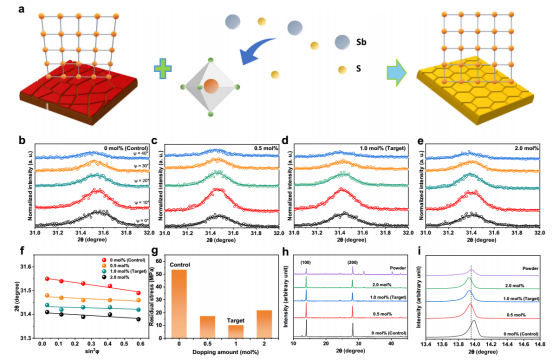

Effects of Sb³⁺ and S²⁻ Doping on Residual Stress and Crystal Structure in Perovskite Thin Films

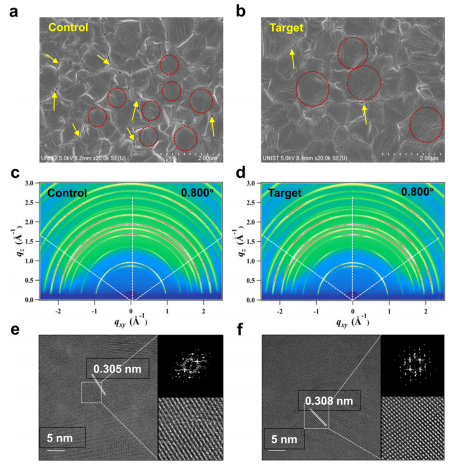

Morphology and Crystallinity Comparison

Theoretical simulations and experimental characterization jointly reveal the multiple benefits of Sb/S alloying:

Lattice Strain Relaxation: Ab initio molecular dynamics simulations indicate that moderate Sb³⁺/S²⁻ doping (~1.56 mol%) modulates Pb–I bond lengths and I–Pb–I bond angles, enhancing the tolerance factor to effectively release lattice stress.

Reduced Residual Stress: Grazing-incidence X-ray diffraction (GIXRD) analysis shows that 1.0 mol% alloyed films exhibit the lowest residual stress (10.5 MPa), less than one-fifth of the control sample (53.7 MPa).

Optimized crystallinity and orientation: GIWAXS and HR-TEM results indicate that Sb³⁺/S²⁻ introduction promotes preferential growth of the α(200) crystal orientation, enhances crystalline quality, and induces more grains to adopt out-of-plane orientation, facilitating charge transport.

Enhanced battery performance and stability

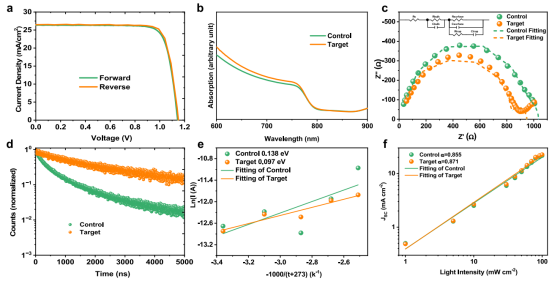

Performance and Characterization Analysis Comparison

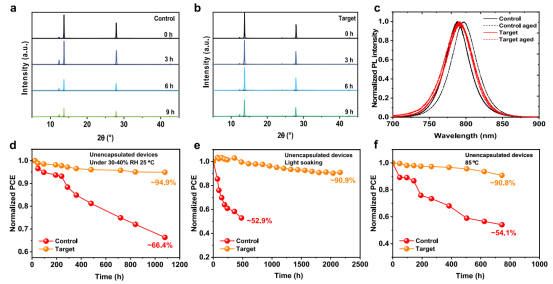

Stability Comparison Analysis of “Control” and “Target” Perovskite Films and Cells

Based on optimized alloyed FAPbI₃, the constructed n-i-p type cell achieved a power conversion efficiency (PCE) of 25.07%, with parameters as follows: Jₛc = 26.48 mA/cm², Vₒc = 1.15 V, FF = 82.33%. This efficiency matches the current highest level achievable with atmospheric fabrication processes.

The performance enhancement stems from: increased light absorption and reduced trap density; carrier lifetime extended from 0.82 μs to 2.1 μs; and decreased interface defects suppressing charge recombination.

Regarding stability, the unencapsulated alloyed cell demonstrated outstanding performance: after 1080 hours at 20–40% RH and 25°C in darkness, it retained 94.9% of its initial efficiency; after 2160 hours of continuous illumination at one sun (in an N₂ environment), the efficiency retention exceeded 90%; and after 744 hours at 85°C, the initial PCE was maintained at 90.8%.

This study successfully developed a novel approach to enhance the performance of FAPbI₃ perovskite materials through Sb³⁺/S²⁻ dual-element alloying. This strategy not only significantly enhances cell efficiency and environmental stability but also enables controlled fabrication under ambient atmospheric conditions, overcoming the limitations of traditional inert atmosphere preparation. It holds promising prospects for industrial application. The simultaneous Sb³⁺/S²⁻ alloying approach provides a robust material design concept and technical pathway for developing highly efficient, stable, and scalable perovskite solar cells.

Millennial Temperature and Humidity Combined Environmental Test Chamber

email:market@millennialsolar.com

The Millennial Temperature and Humidity Combined Environmental Test Chamber utilizes an imported temperature controller, enabling multi-stage temperature programming with high precision and excellent reliability to meet testing requirements under various climatic conditions.

▶ Temperature Range: 20°C to +130°C

▶ Temperature and Humidity Range: 10%RH to 98%RH (at +20°C to +85°C)

▶Compliant with Testing Standards: IEC61215, IEC61730, UL1703, and other certification requirements

The Millennial Temperature and Humidity Environmental Test Chamber delivers a comprehensive climate simulation solution for photovoltaic module testing. It precisely accelerates accelerated aging experiments and fully ensures module reliability certification. By leveraging standardized intelligent control to drive industrial advancement, it provides robust support for breakthroughs in highly stable, scalable perovskite modules.

Related Products