Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Crystalline Silicon Solar Cell Production Process - High Temperature Annealing

Date : 26 September 2023Views : 810

In the production process of crystalline silicon solar cells, high-temperature annealing can optimize the lattice structure of the cell surface through high-temperature treatment, thereby improving the light transmittance and conductivity of the crystalline silicon solar cells after ion implantation. The FTIR Spectrometer owned by Millennial Solar can obtain information on the microstructure of crystalline silicon solar cells and understand the passivation status of the cells after ion implantation based on the obtained H content, thereby helping photovoltaic cell manufacturers to successfully ensure the performance of the cells.

![]()

What is high temperature annealing of crystalline silicon solar cells?

High-temperature annealing of crystalline silicon solar cells is a very important step in the solar cell production process. It mainly uses high-temperature treatment to optimize the surface lattice structure of the cell and improve the surface transmittance and conductivity of the cell,thereby improving the photoelectric conversion rate of crystalline silicon solar cells. Crystalline silicon solar cells that have undergone high-temperature annealing processes have higher performance and higher photoelectric conversion stability than ordinary solar cells.

![]()

High Temperature Annealing Process Principle

The principle of the high-temperature annealing process of solar cells is to change the internal structure of the cell through high-temperature treatment, thereby making the surface of the solar cell more conducive to light absorption and increasing the light transmittance of the photovoltaic cell. During the annealing process, due to the heat absorbed by the cell surface, the cell structure changes, thereby affecting the electrical and mechanical properties of the cell.

At the same time, the high-temperature annealing process will also affect the microstructure of the solar cell and remove the internal lattice defects. The reason is that at high temperatures, the diffusion rate of lattice defects will increase as the temperature increases. Therefore, the high-temperature annealing process can directly improve the performance of solar cells, increase their service life and photoelectric conversion rate.

![]()

High Temperature Annealing Process

Before starting the annealing process, the surface of the cells needs to be cleaned first. In order to prevent the surface of the cells from being damaged, a solution that is not too strong needs to be used during the cleaning process and put the cells in a light-shielding bag to prevent them from being exposed to light and affecting the performance of the cells.

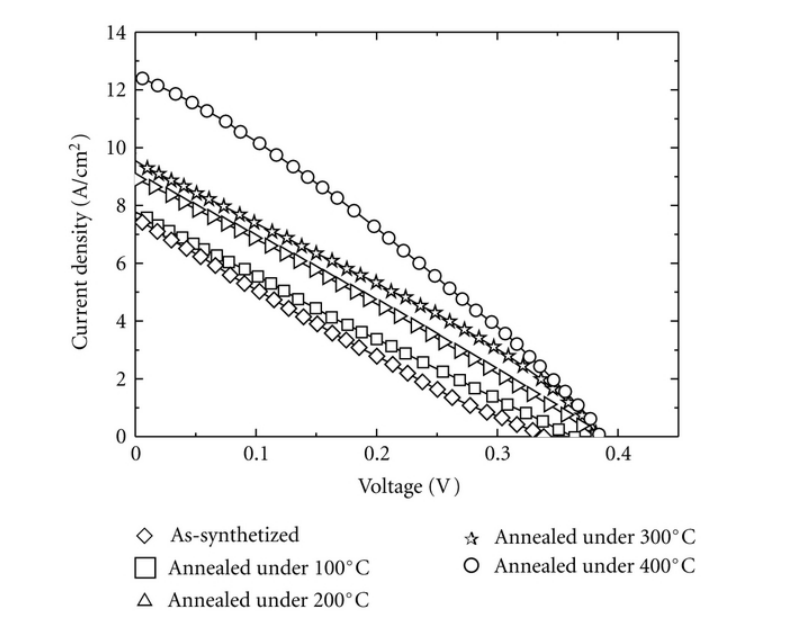

Effect of annealing at different temperatures on photovoltaic cell performance

The annealing processes of solar cells are commonly used atmosphere annealing and rapid thermal annealing. Atmosphere annealing refers to annealing performed in a specific atmosphere, usually nitrogen or hydrogen. Rapid thermal annealing uses rapid heating technology to heat the cell to a high temperature in a short period of time and then cool it quickly. The control of time and temperature during annealing is crucial, and the selection of temperature and time will vary depending on the cell. Generally speaking, the commonly used temperature will be controlled at 400-600℃, and the time will be controlled at about 5-20 minutes. In addition, annealing requires precise control of temperature and time to ensure the performance of solar cells.

After completing the annealing, the solar cell needs to be tested for effectiveness to ensure the qualification of the annealing process. The main test is the performance parameters of the solar cell. At the same time, the surface and structure of the solar cell also need to be inspected to ensure whether there are any damages and defects, which will affect the subsequent process of the cell and cell performance.

![]()

Millennial FTIR Spectrometer

E-mail: market@millennialsolar.cn

Millennial FTIR Spectrometer is a powerful device for studying the relationship between various molecules in the infrared band or absorption radiation patterns and molecular structure. It is mainly used for the analysis of material structure.

The relationship between various vibration modes and structures of local atoms or atomic groups in solid materials can also be studied to obtain information on the local structure of the measured object.

●Calculate R structure factor and H content with one click

●Super large spectral range up to 7800~350cm-1

●Spectral wave number accuracy is better than 1.0cm-1, wave number repeatability is better than 0.1cm-1

●Imported high-sensitivity DLATGS detector, light transmittance accuracy ≤0.5T

●Saving labor, easy to operate, greatly improving work efficiency

High-temperature annealing is an important process that directly affects the transmittance and conductivity of solar cells. The emergence of high-temperature annealing technology has laid a solid performance foundation for solar cells in the production process. The FTIR Spectrometer produced by Millennial Solar can efficiently detect the passivation of solar cells after high-temperature annealing, and provide intuitive data analysis for battery manufacturers, thereby helping them produce higher-quality solar cells!