Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

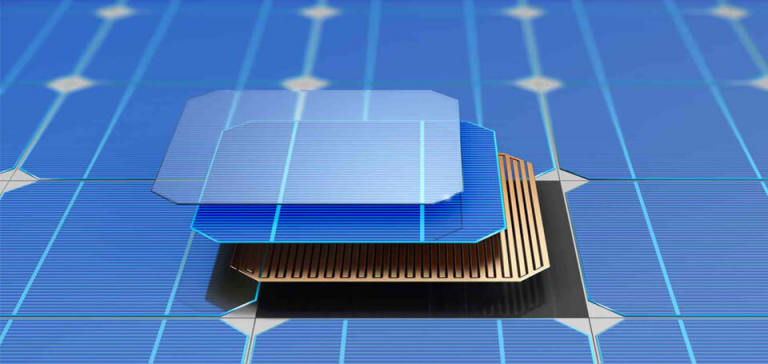

Heterojunction Solar Cell Structure - ITO Film

Date : 26 October 2023Views : 955

In the structure of heterojunction solar cells, the impact of ITO films on their performance is very important and direct. The quality of the ITO film itself and the process of preparing the ITO film can often directly determine the later production process of heterojunction solar cells and whether the actual application is scientific and effective. Four-Point Probe Tester produced by Millennial Solar, according to the strict measurement requirements put forward by photovoltaic cell manufacturers, the sheet resistance/resistivity of a series of cells such as heterojunction solar cells after depositing ITO films can be scientifically and accurately measured efficiently. It enables photovoltaic cell manufacturers to scientifically evaluate whether their data meets performance standards. This is very effective in enabling heterojunction solar cells to obtain reasonable quality assurance basis in other production steps after the deposition process and in practical applications!

![]()

What is ITO film

The ITO film is an N-type oxide semiconductor - indium tin oxide. Because it uses tin and oxygen as donors, it can maintain stable conductivity and visible light transmittance at room temperature. Because of its high mechanical hardness and good chemical stability, it can become a commonly used thin film material for heterojunction solar cells.

In its deposition process, in order to evaluate whether the ITO film provides high transmittance and conductivity for heterojunction solar cells, it is necessary to conduct scientific testing through some high-precision solar cell testing equipment. Millennial Solar produced Four-Point Probe Tester, this equipment can efficiently detect the performance of heterojunction solar cells after depositing ITO films. Photovoltaic cell manufacturers can conduct scientific evaluations based on the real-time data generated by the testing equipment, and make appropriate adjustments and optimizations to the cell performance based on the data. Thus producing heterojunction solar cells supported by scientific evidence!

![]()

Preparation method of ITO film

There are many methods for preparing ITO thin films. Commonly used methods include magnetron sputtering, vacuum evaporation, chemical vapor deposition, etc. Different preparation methods will affect the structure, performance and cost of ITO films. Generally speaking, magnetron sputtering can obtain uniform, dense, and low-resistivity ITO films, but the equipment cost is high; the vacuum evaporation method can obtain thicker ITO films, but the light transmittance is low; the chemical deposition method can obtain ITO films prepared at lower temperatures, but the quality is unstable.

![]()

Factors affecting the conductive properties of ITO films

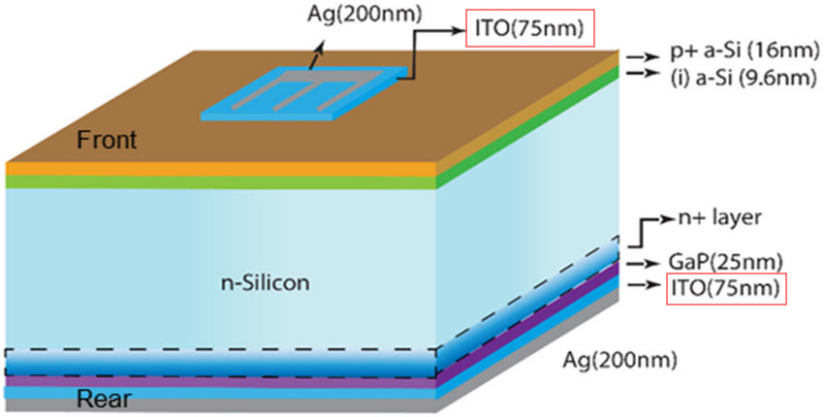

The surface resistance (R), film thickness (d) and resistivity (ρ) of the ITO film are related to each other. The calculation formula between the three is: R=ρ/d. Generally speaking, it is easier to obtain different film thicknesses when preparing ITO films. The required film thickness can be obtained by adjusting the deposition rate and deposition time during film deposition, and precise film thickness and uniformity control are carried out through corresponding process methods and means.

Schematic diagram of the thickness of ITO film

The resistivity of the ITO film is the key to the ITO film preparation process, and the resistivity is also an important indicator for measuring the performance of the ITO film. When the carrier concentration and carrier mobility are greater, the resistivity of the film will be smaller, and vice versa. The carrier concentration is related to the composition of the ITO film material, that is, the tin content and oxygen content that make up the ITO film itself. In order to obtain a higher carrier concentration. This can be achieved by adjusting the tin content and oxygen content of the ITO film deposition material; the carrier mobility is related to the crystallization state, crystal structure and defect density of the ITO film. In order to obtain higher carrier mobility, factors such as the deposition temperature, sputtering voltage, and film formation conditions during film deposition can be reasonably adjusted.

![]()

Millennial Four-Point Probe Tester

E-mail: market@millennialsolar.cn

Millennial Four-Point Probe Tester can quickly and automatically scan samples up to 230mm to obtain sheet resistance/resistivity distribution information at different locations of the sample.

●Ultra-high measurement range, measuring 1MΩ~100MΩ sheet resistance

● High-precision measurement, dynamic repetition rate can reach 0.2%

● Fully automatic multi-point scanning, multiple preset schemes can also be customized and adjusted

● Rapid material characterization and automatic calculation of correction factors

![]()

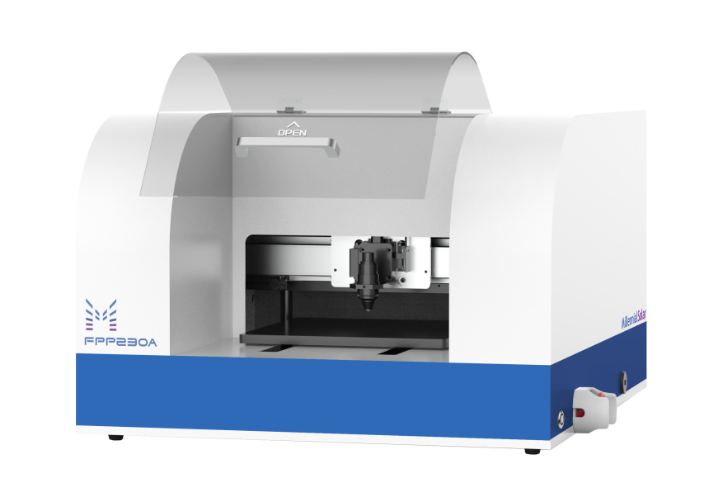

Millennial Built-in Four-Point Probe Tester

E-mail: market@millennialsolar.cn

FPP230 Auto is a Built-in Four-Point Probe Tester specially designed for photovoltaic process monitoring. It can quickly and automatically scan the sample to obtain the sheet resistance distribution information at different positions of the sample. The measurement size can be customized according to the size of the customer's sample.

●Measurement range meets sheet resistance of 1μΩ~100MΩ

● Can match automated equipment and can be traced at any time

● Supports fully automatic multi-point scanning and perfectly connects with the automated production process of the production line

● Provide good electrical contact while ensuring fragmentation

●The number of measurement points can be customized according to customer needs

In the deposition process of heterojunction solar cells, photovoltaic cell manufacturers hope to ensure the performance of the cells through efficient preparation of ITO films. However, whether it is efficient or not often requires scientific quality testing to determine. Millennial Four-Point Probe Tester can ensure the accuracy of measurement and the integrity of samples during industrial production through its unique non-destructive testing technology. Based on this feature, it can be perfectly suitable for large-scale industrial production testing. It is An important helper for photovoltaic cell manufacturers to test solar cells!