Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

The "Scientific Prosecutor" of Screen Printing Technology

Date : 12 March 2024Views : 885

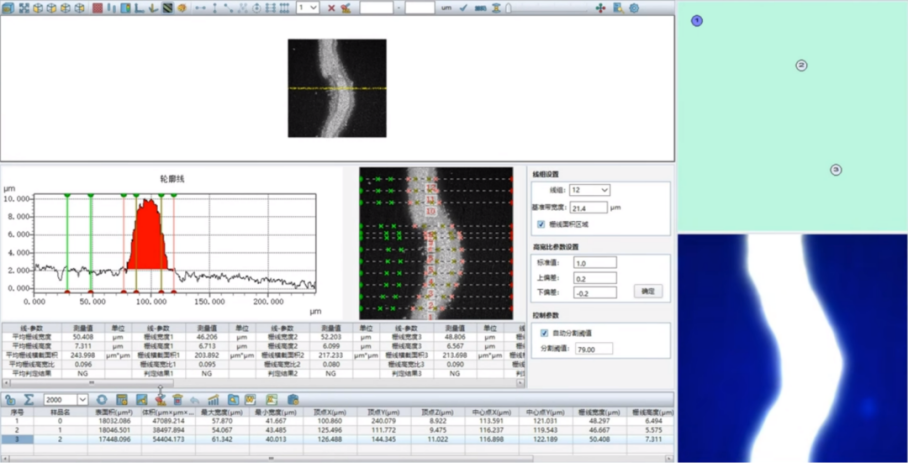

Evaluation refers to the conclusion drawn after judgment and scientific analysis of a thing, and the same is true for the evaluation of the quality of the screen printing process. After the screen printing production process is completed, in order to scientifically evaluate the quality of the production process, it must be indirectly scientifically tested from many aspects. 3D Confocal Microscope has fully accomplished this. This equipment can be used to detect the quality of the screen printing process by understanding the data parameters of the grid lines of solar cells, such as width, height, aspect ratio, etc. to reflect and evaluate whether the quality of the screen printing process meets industrial standards. In this way, we can truly achieve the purpose of getting substantial praise from the majority of photovoltaic enterprise users by virtue of the functions and technologies of the equipment.

3D Confocal Microscope – scientific evaluation of screen printing processes

The reason why a complete production process is complete needs to be evaluated through subsequent testing processes. In order to scientifically and intelligently evaluate the quality of the screen printing process, the 3D Confocal Microscope, which is the "scientific prosecutor" of the screen printing process, was born. This equipment is an optical instrument specially used in the photovoltaic industry to inspect the quality of grid lines and textures on the surface of solar cells, its targeted inspection of screen printing process quality is the best in the industry!

● Accurate and reliable 3D measurement to achieve real-time confocal microscopy images

●Ultra-high confocal lens, Z-axis display resolution can reach 1nm

● Maximum comprehensive magnification of 198-39966 times, accurate measurement of sub-micron morphology

● Fully automatic measurement and rapid data generation

● Comprehensive feedback on cleaning texturing and screen printing processes

● Gives a variety of confocal color images

● Integrated operation, Chinese interface, friendly measurement and analysis software

What exactly is screen printing?

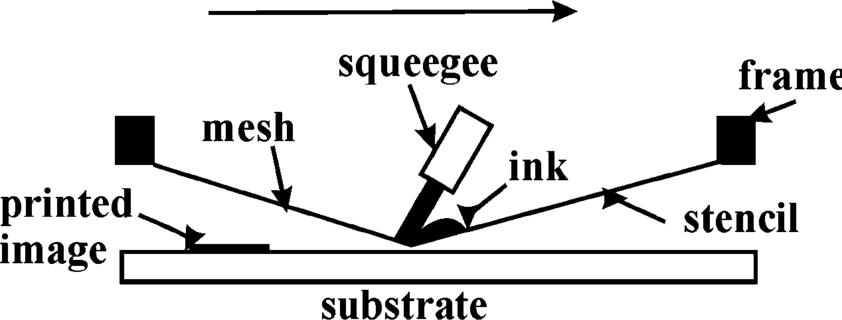

The screen printing process is a method that uses a screen as a printing plate and uses photosensitive plate making to make the mesh of the graphic part transparent with ink, and the mesh of the non-graphic part impermeable to ink.

Specifically, the working principle of the screen printing process is to use the basic principle that ink can pass through the graphic part of the screen printing screen, and the non-graphic part of the mesh is blocked for printing. When printing, pour ink into one end of the screen printing screen, use a scraper to apply a certain amount of pressure on the ink part of the screen printing screen, and at the same time move towards the other end of the screen printing screen at a constant speed. The ink is removed from the graphic part of the screen by the scraper during the movement.

Screen printing process diagram

Due to the viscosity of the ink, the imprint is fixed within a certain range. During the printing process, the scraper is always in line contact with the screen printing screen and the substrate, and the contact line moves with the movement of the scraper.

Since there is a certain gap between the screen printing screen and the substrate, the screen printing screen generates a reaction force on the scraper through its own tension during printing. This reaction force is called rebound force.

Scientific evaluation of grid line measurement - clear and objective parameter characterization

3D Confocal Microscope not only has a fully automatic measurement function, but also can accurately measure the surface of solar cells through ultra-high measurement accuracy and high-tech confocal microscopy technology. However, other similar 3D microscopes often suffer from a series of problems encountered during measurement, such as long measurement time, low measurement accuracy, and cumbersome measurement procedures, which affect the manufacturer's normal inspection after the screen printing and cleaning and texturing processes.

Compared with other 3D microscopes, the 3D Confocal Microscope solves this problem to a great extent. And when measuring the grid lines during the inspection, it can perfectly characterize a series of data parameters such as the width, height, and aspect ratio of the grid lines through its own functions and technology, and use these parameters to compare with the screen printing stencil to help manufacturers conduct detailed proofreading and calibration, truly scientifically evaluate grid line measurements and objectively characterize data parameters!

The 3D Confocal Microscope can not only scientifically evaluate the quality of the screen printing process, but also detect and characterize the cleaning and texturing production process and its parameters through its own functions, thereby helping manufacturers produce high-quality solar cells! From the past to the present and into the future, Millennial Solar will maintain and continue to work hard for the development of the photovoltaic industry and the strategic plan of "carbon neutrality" to create a new photovoltaic tomorrow!