Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Explore Photovoltaic Module Packaging Materials | PET Backsheet Tensile Test

Date : 27 March 2024Views : 1030

As a green energy source with wide distribution and abundant reserves, solar energy has attracted much attention. In photovoltaic systems, PET (polyethylene terephthalate) is the main material for photovoltaic backsheets. Partial discharge (PD) is one of the challenges that leads to the deterioration of PET insulation and mechanical properties, which has a serious impact on the service life of photovoltaic backsheets. The content of this issue will focus on the elongation at break and tensile strength of PET after partial discharge. Solar Cell Comprehensive Tensile Tester from Millennial Solar, with its horizontal and vertical integrated design, helps manufacturers produce high-quality photovoltaic modules!

Photovoltaic module backsheet core structure - PET

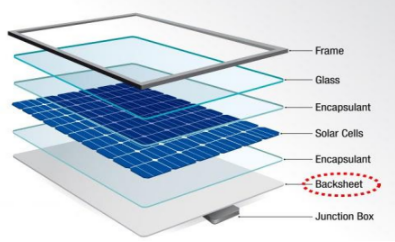

Solar panels are mainly composed of photovoltaic glass, ethylene vinyl acetate (EVA) film, solar cells, junction boxes, backsheets, etc., as shown in Figure 1. A large area of the backplane is in contact with the external environment. It must not only maintain excellent performance in harsh environments, but also ensure long-term reliability.

Figure 1. Schematic diagram of solar panel structure

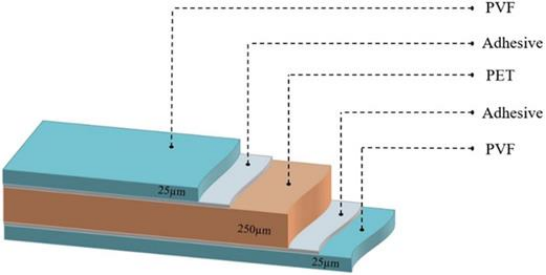

The common backplane structure is TPT[PVF/PET/PVF], as shown in Figure 2. The core part is usually made of PET with heat resistance, chemical resistance and electrical properties. The life of the backsheet directly affects the performance of the photovoltaic module and is closely related to the safe operation and economic benefits of the solar power station.

Figure 2.TPT backsheet structure

PET backsheets need to maintain electrical insulation. Studies have found that the path between the EVA film and the backsheet significantly increases the risk of partial discharge. Leakage current caused by potential-induced decay (PID) will affect the backsheet, eventually leading to electric shock. wear. The service life and reliability of the backsheet are evaluated by comparing different partial discharge durations and the change mechanisms of PET elongation at break (EAB) and tensile strength (TS) after partial discharge.

Tensile test of PET samples

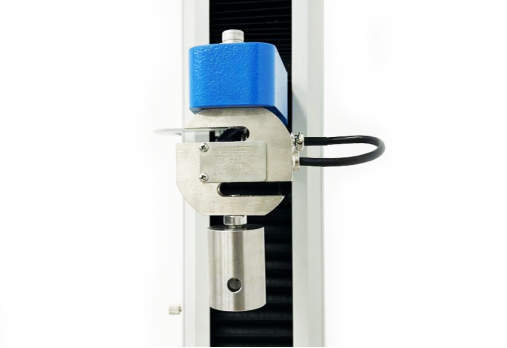

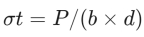

Fix the sample vertically in the fixture as shown in Figure 3. Use the sample after partial discharge to conduct a tensile test to analyze its mechanical properties, including elongation at break and tensile strength. The tensile speed is 50±5mm/min.

Figure 3. Fixture diagram

Tensile test results

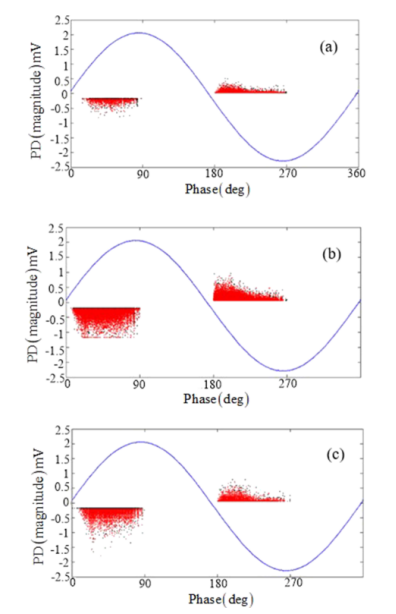

The phase-resolved partial discharge (PRPD) results corresponding to the test results are shown in Figure 4. The red part in the figure is the area where partial discharge signals appear intensively, and the black part is the area with less signal. For the PRPD diagram with a small discharge amount, the discharge time Relatively short, the frequency is relatively high; the PRPD diagram with higher discharge intensity has a relatively long discharge time and a relatively low frequency; as the partial discharge duration increases, the number of partial discharge points increases significantly, and the amplitude also increases significantly.

Figure 4. PRPD diagram after 30(a), 60(b) and 120(c) minutes

Conduct a tensile test on the sample after partial discharge: elongation at break and tensile strength are two common indicators that reflect the mechanical strength of insulating materials.

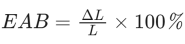

Elongation at break refers to the ratio of the displacement value of the sample when it breaks during the entire tensile test to the original length, expressed in percentage, and the formula is as follows:

In the formula, L is the original length of the material, and ΔL is the displacement length after the material test.

Tensile strength reflects the resistance to fracture of infinite (or tiny) uniform deformation and is formulated as follows:

where P is the maximum tensile force on the material, b and d are the thickness and width of the material respectively.

Figure 5 shows the sample before and after the tensile test, with the tensile area located within the red dashed line.

Figure 5. PET sample before fracture (a) and after fracture (b)

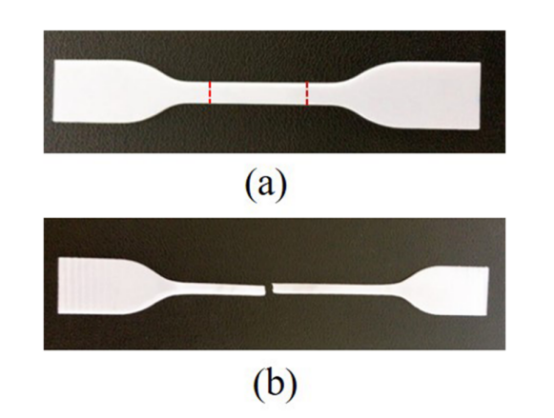

Figure 6 shows the relationship between force and displacement of PET that is not partially discharged in the tensile test: the tensile process of the material first goes through the elastic deformation stage, deforms after reaching the yield point, and breaks after reaching the breaking point.

Figure 6. Relationship between force and displacement of PET without partial discharge

After substituting the test data of samples without partial discharge into the above two formulas, it was found that the calculated values of elongation at break and tensile strength are almost the same as the experimental measured values.

This leads to the conclusion that the data measured in the experiment satisfy the above two formulas at the same time.

As the partial discharge time increases, PET is prone to rupture after hydrolysis reaction, which reduces the mechanical properties, accelerates the insulation damage of the material, and ultimately leads to a decrease in the reliability of the material and equipment.

Solar Cell Comprehensive Tensile Tester

E-mail: market@millennialsolar.com

Introduction:

Solar Cell Comprehensive Tensile Tester adopts a horizontal and vertical integrated design. The vertical test module is equipped with a force sensor of 50N and 1000N. It can be used for testing static physical properties such as tensile, compression, and bending of materials. It is specially used for silicon wafers and silicon wafers in the photovoltaic industry. Test the peeling force and tensile strength of materials, photovoltaic cell modules and other related products.

Fulfill the standard:

GB/T16491-2009, GB/T16491-96, JB/T17797-95

Features:

•Unique horizontal and vertical integrated design, capable of both horizontal 180° peel strength test and vertical cell bending test;

•The horizontal test module can use up to 28 sensors at the same time;

•The vertical test module can be used for tensile, compression, bending and other tests of photovoltaic cells or materials;

•Single-side test time is less than 1 minute, at least 10-18 times faster than single-group test speed

The quality and performance of photovoltaic modules are crucial to the long-term stable operation of solar power generation systems. Solar Cell Comprehensive Tensile Tester, with its carefully designed test details and multi-busbar test function, is widely used to evaluate the mechanical properties of components and has become an indispensable and important testing equipment in the photovoltaic industry. Millennial Solar will help through continuous innovation and technology upgrades. The solar power industry is moving towards a more sustainable and prosperous future.