Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Effects of Different Sizes and Temperature Velocities of Ice Balls on Hail Impact Test

Date : 29 March 2024Views : 1045

During the operation of photovoltaic systems, modules face various environmental challenges, including hail. When hail hits the surface of a module at high speed, it may cause serious surface damage to the photovoltaic system and breakage of connecting wires. Therefore, understanding the impact of hail on photovoltaic modules and the impact resistance of the modules is crucial to ensure the reliability and durability of the system. This issue of Millennial Solar will delve into the impact of hail on photovoltaic modules and related tests and solutions.

IEC61215 standard-hail impact test

The hail impact test is to use artificial ice balls instead of hail to hit photovoltaic modules from different angles with a certain momentum, and detect the appearance defects and electrical performance attenuation rate of the modules to determine the ability of the modules to withstand hail impact.

The hail impact test can be carried out through a hail impact testing machine. The working principle is that the air compressor compresses the air into the air storage tank, and an external pressure gauge and a gun barrel with a certain inner diameter (such as 25mm) are connected. A solenoid valve is installed at the connection, and is controlled to open by the solenoid valve. A photoelectric speed measuring device is installed at the front end of the barrel. Adjust the pressure gauge to make the ice puck reach the impact speed required by the standard. Make an ice ball mold with a certain inner diameter (such as 25mm), place the made ice ball in the barrel, open the solenoid valve, and the compressed air pushes the ice ball to hit the solar photovoltaic module at a certain speed (such as 23m/s). After the module is hit by a pilot ice ball, the quality of the module is determined by visual inspection, I-V test, and insulation resistance test. The test steps are as follows:

1. Preparation

2. Install photovoltaic modules: Install the photovoltaic modules to be tested and ensure that their position and fixation method meet the test requirements.

3. Set test parameters: set parameters such as impact speed, angle and energy.

4. Conduct the test: Launch hail samples: Activate the launch system and launch simulated hail samples.

5. Data analysis: analyze the damage: evaluate the damage of photovoltaic modules under hail impact, including appearance deformation, cracking, changes in electrical properties, etc.; result evaluation: compare the test results with the IEC 61215 standard to evaluate the impact resistance of the module and durability. Relevant safety operating procedures should be followed during the test to ensure the safety of personnel and equipment.

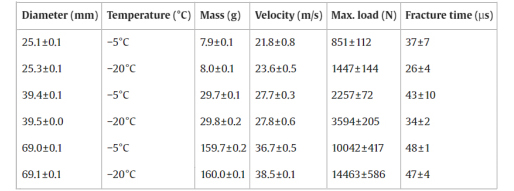

Effects of hockey puck size, speed and temperature on component impact resistance

Ice balls with diameters of 25, 40 and 70 mm were prepared, and the spherical ice samples were accelerated with an air gun to reach the target speed. Use round glass tubes of different inner diameters to guide the puck. After ice ball samples of three different diameters were shot onto the Hopkinson rod at the same speed at two different freezing temperatures (-5°C and -20°C), the test results of load and response time are shown in Table 1 Including the sample temperature and mass as well as the diameter of the sample, a monotonic increasing trend can be observed in each test group. However, there is still a certain degree of discreteness in the overall data, and lower temperatures (-20°C) will lead to increased peak loads and shortened fracture times.

Table 1. Experimental results of ice balls with different diameters

By comparing the average values for samples with a diameter of 40 mm, it was found that a decrease in temperature results in a doubling of the loading rate, resulting in a higher stress rate. For 25, 40 and 70 mm ice balls at -20°C, the peak forces were approximately 70%, 59% and 44% higher than those at -5°C at the same speed.

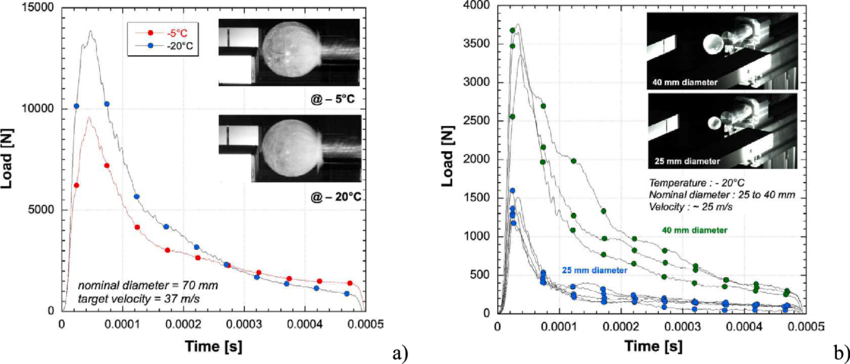

Figure 2 compares the load versus time curves of a 70mm diameter sample at two temperatures. Lowering the sample temperature will result in an increase in peak force and a decrease in the time required to reach peak force; and load versus time curves at -20°C for 25 and 40 mm samples.

Figure 2. Load versus time curve

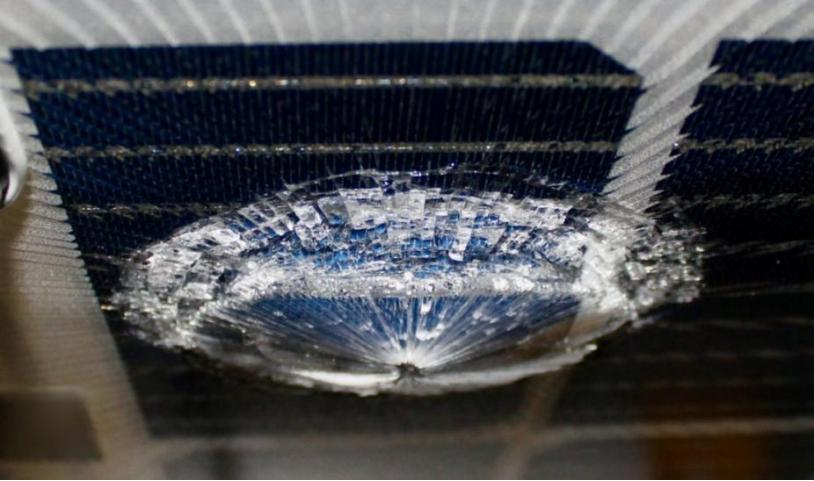

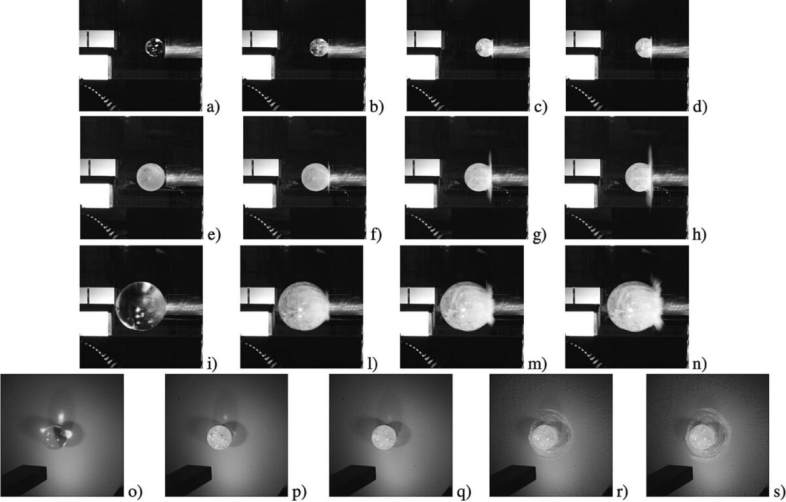

Figure 3 is a photo taken during the impact of an ice ball with three diameters. The impact of the ice ball on the photovoltaic cells and the resulting cracks can be seen in the picture.

Figure 3. Effect of ice hockey samples on Hopkinson rods and cells (12800 fps)

The results show that as the size and impact speed increase, the peak force and the corresponding time increase; the ice ball temperature also plays an important role; lower temperature leads to higher peak force and shorter peak time; that is:

The lower the temperature, the greater the peak force, the shorter the peak time. Studying the impact resistance of photovoltaic modules can help mitigate damage. According to the IEC61215 standard, photovoltaic modules should withstand at least the impact of 25 mm hail fired at a speed of 80 km/h. However, climate change is intensifying. In environments with frequent hail weather, the actual hail impact that needs to be withstood is 40 mm or more. More, larger diameters and higher speeds allow manufacturers to evaluate products with adequate safety margins.

Hail Impact Testing Machine

Understanding the impact of hail on photovoltaic modules is crucial to ensuring the stable operation of photovoltaic systems. The hail impact test is designed to simulate hail impact conditions in real environments and help manufacturers better withstand challenges brought by the natural environment through test evaluation.

E-mail: market@millennialsolar.com

Introduction:

Hail Impact Testing Machine is a hail testing equipment developed based on the MQT17 clause of the IEC61215 standard. It uses air pressure to impact ice balls of different diameters (artificial ice balls are used to simulate hail), and impacts the modules at a constant speed to simulate the impact of hail weather on photovoltaic modules. , verify the impact resistance of photovoltaic modules.

Fulfill the standard:

IEC61215 standard MQT17 clause

Features:

•High-precision infrared speed sensor

•Configure a variety of fixtures to meet different structures

•Meet the needs of launching ice pucks with diameters of 25, 35 and 45mm

As an important tool to ensure the quality and stable operation of photovoltaic products, the photovoltaic module hail impact testing machine plays an indispensable role in the solar energy industry. Hail Impact Testing Machine from Millennial Solar simulates real hail impact environments to ensure the reliability of components in severe weather. It is a key means to evaluate the impact resistance of photovoltaic modules. Millennial Solar is willing to make better use of solar energy, a clean energy, and contribute to building a better future through continuous innovation and efforts.