Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

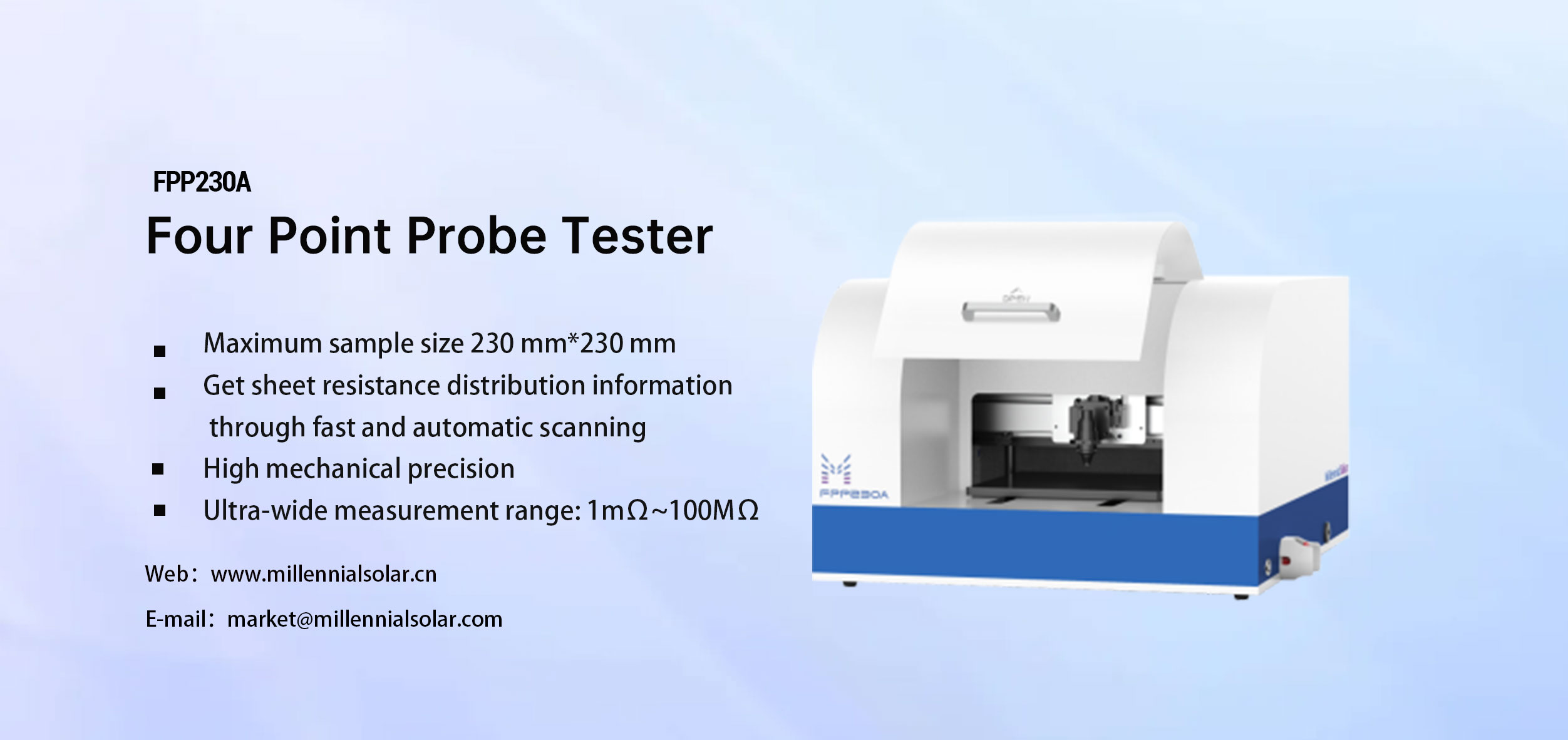

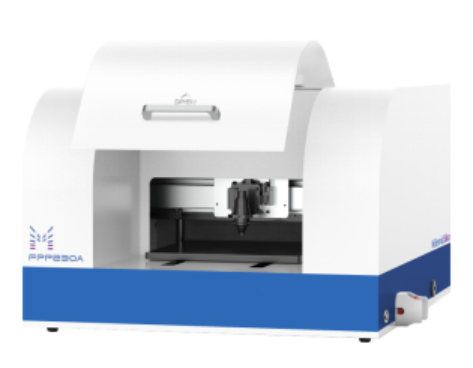

FPP230A Four Point Probe Tester: Professional Solution for Resistivity Measurement

Date : 29 May 2024Views : 970

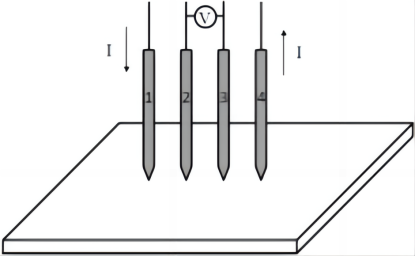

Four Point Probe Tester is a device used to measure the sheet resistance of photovoltaic cell materials. Its working principle is based on four point probe technology. Four point probe technology calculates the resistivity of the sample by placing four probes on the surface of the sample and using the current between two of the probes and the voltage difference between the other two probes. Four Point Probe Tester FPP230A is a high-precision test equipment designed for the photovoltaic industry. Its design concept and technical features are mainly aimed at the measurement needs of silicon wafer resistivity in the photovoltaic industry. According to the information provided, this tester can quickly and automatically scan samples up to 230mm * 230mm to obtain square resistance/resistivity distribution information, which is crucial for evaluating the quality of solar cell materials.

Four Point Probe Production Process and Improvement

The design and manufacturing process of the Four Point Probe Tester probe head draws on the manufacturing process of mechanical watch movements. This reference is mainly reflected in the requirements for precision and stability. In the production process of the Four Point Probe Tester probe head, high-temperature epoxy casting of the cone head is a key step, which requires extremely high precision and stability to avoid casting leakage and voids.

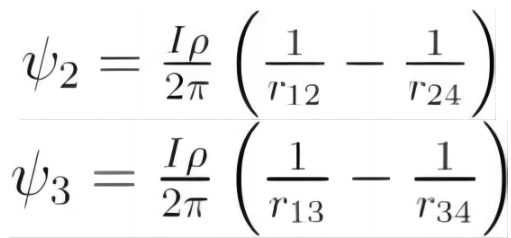

Schematic diagram of resistivity measurement using the linear four point probe method

Performance: The improved Rymaszewski method automatically eliminates the influence of the longitudinal movement of the probe, and it is applied to the inclined square probe test method; on the basis of the inclined square four-probe mechanical platform, the hardware design and software programming of the entire test circuit are completed, and an inclined square probe analyzer with a constant current source with high precision and high stability is developed.

Material: The use of ruby bearings to guide tungsten carbide probes is an advantage. Ruby bearings can effectively support the stability of tungsten carbide probes at high speeds due to their excellent wear resistance and low friction properties, thereby improving the overall performance and life of the probe head. The choice of this material not only improves the functionality of the probe head, but also extends its service life. It is an innovative application that conforms to the development trend of modern precision instruments.

Four Point Probe Tester probe head draws on the manufacturing process of mechanical clock movements and uses ruby bearings to guide tungsten carbide probes to ensure high mechanical precision and long service life. The dynamic test repeatability (close to the real scene) can reach 0.2%, which is the industry-leading level.

Probe head parameters

Probe spacing: 1.00mm

Probe material: tungsten carbide

Probe pressure (optional): 3~5N (thin film)

Mechanical drift: < 0.3%

Bearing inner hole and probe spacing: < 6μm

Calculation of resistivity of semi-unbounded samples with sheet resistance

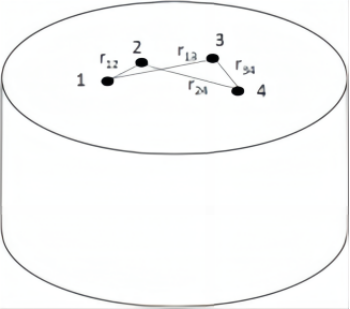

When measuring the sheet resistance of photovoltaic cell materials and calculating the resistivity of semi-unbounded samples, the four point probe method is a commonly used method for measuring sheet resistance. It calculates resistivity by measuring the current and voltage on two diagonals.

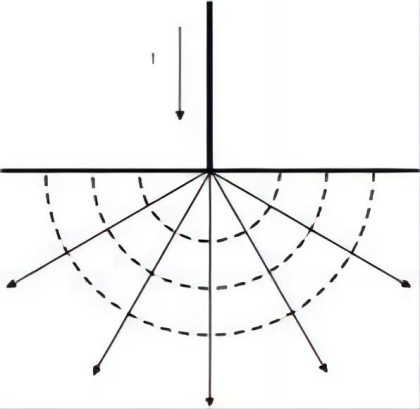

This method is suitable for samples of different thicknesses. For semi-unbounded samples, that is, samples whose boundary conditions are not completely defined, a method based on a mathematical model can be used to calculate the resistivity. When the sample thickness and the distance from the edge of the sample to the probe are much larger than the probe spacing, the sample under test can be considered to be a semi-unbounded sample. A point current source with an intensity of l is introduced by the probe on this semi-unbounded sample. If the material is uniform and isotropic, the current distribution is spherically symmetric, and the resulting equipotential surfaces are concentric spherical surfaces.

Schematic diagram of concentric spherical equipotential surfaces generated by a point current source in a semi-unbounded sample

The schematic diagram of resistance testing using an irregularly positioned four point probe on a semi-unbounded sample is shown in the figure below.

Points 1 and 4 are the locations of the current input and output probes, respectively, and points 2 and 3 are the locations of the voltage drop measurement probes. Points 1 and 4 can be regarded as point current sources, so the potentials of points 2 and 3 are

Four Point Probe Tester

E-mail: market@millennialsolar.com

● Maximum sample size 230 mm * 230 mm

●Quick, automatic scanning to obtain square resistance/resistivity distribution information at different locations

●Ultra-wide measurement range 1mΩ~100MΩ, covering most resistance measurement application scenarios

● Industry-leading dynamic test repeatability up to 0.2%

Four Point Probe Tester FPP230A has become an indispensable test equipment with its excellent design and technical advantages. It has industry-leading dynamic test repeatability, and the test repeatability close to the real scene is as high as 0.2%. In addition, its ultra-wide measurement range (1mΩ~100MΩ) makes it suitable for various resistance measurement application scenarios, including solar cells, semiconductors, alloys and conductive films. With FPP230A, the measurement of thin layer resistance of photovoltaic cell materials becomes more accurate and efficient, providing strong support for the quality assessment of photovoltaic materials.