Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Introduction to Generation and Prevention Measures of Hot Spot Effect of Modules

Date : 5 August 2024Views : 870

Bypass diodes are standard accessories in photovoltaic modules. Their function is to eliminate the hot spot effect caused by reverse bias due to mismatch, which will cause power reduction and damage to photovoltaic modules. Therefore, the design and corresponding detection of a reliable bypass diode device are crucial. Millennial Bypass Diode Tester ME-PV-BDT tests the bypass diode function test and thermal performance test in the IEC61215 standard. It is equipped with temperature environment chamber to evaluate the reliability of bypass diodes in high temperature working environments, providing an important reference for protecting circuit stability, circuit design and optimization, and fault analysis.

Mismatch effect in photovoltaic modules

Mismatch effect refers to the phenomenon that occurs when interconnected solar cells or modules do not have the same performance or do not work under the same conditions. Mismatch occurs when the parameters of one cell in the module are significantly different from the others.

The impact and power loss caused by the mismatch effect depend on the operating point, circuit structure layout and parameters of the affected solar cells in the photovoltaic module.

Because most photovoltaic modules are in series, series mismatch is the most common type of mismatch. Series mismatch is divided into short-circuit current mismatch and open-circuit voltage mismatch, among which short-circuit current mismatch is the most common and most serious. It is usually caused by shadowing or cell failure.

Hot spot effect

1. When the local cells of the photovoltaic module are blocked by leaves, dust, bird droppings and other objects;

2. A cell in the photovoltaic module itself has defects, and the power generation efficiency is lower than that of other cells;

3. Poor welding during the module manufacturing process and the PID potential induced attenuation effect in the later stage;

Once the total operating current of the module exceeds the short-circuit current of these "problem cells", the voltage of these cells will be biased into a load, thereby consuming the power of other "normal cells" inside the module. Therefore, the "problem cell" will be transformed into an energy-consuming component and heated by the energy generated by the cells in the same string, resulting in local overheating, thus producing a hot spot effect.

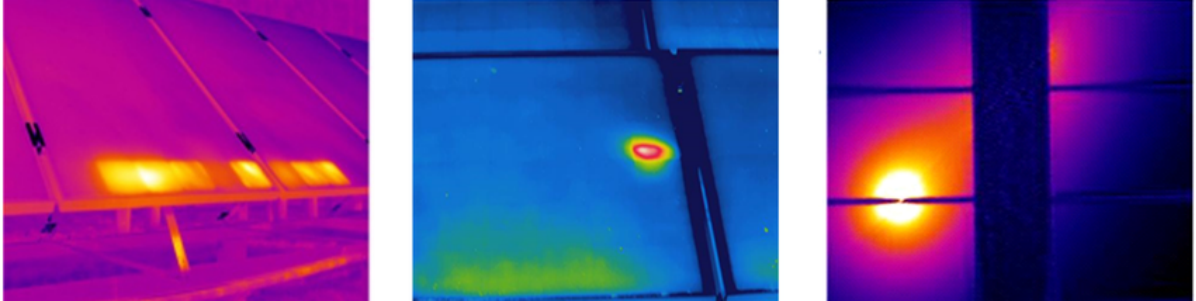

(Left) Shadow causes (Middle) Cell damage (Right) Hot spot effect of photovoltaic modules caused by grid line damage

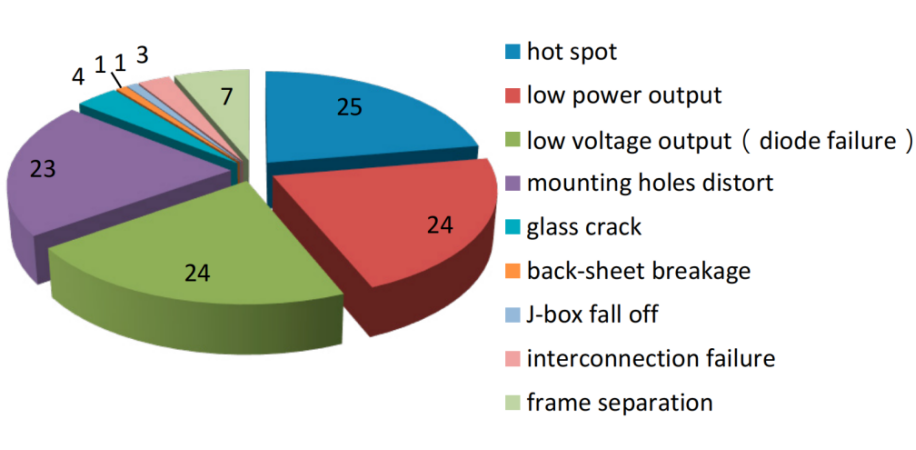

A foreign organization conducted a three-year investigation into the causes of photovoltaic module degradation and failure, performed performance test box analysis, and concluded that 25% of the problems were caused by the hot spot effect.

Statistics on the distribution of causes of degradation and failure of photovoltaic modules by a foreign institution

If the heat generated by the hot spot effect is too great, it may cause local yellowing, burning, bulging, delamination, or even glass breakage on backplane. In severe cases, it may cause a fire.

Effective methods to reduce hot spot effect

By using bypass diodes at both ends of each string of cells, the damage caused by hot spot effect to the module can be effectively avoided.

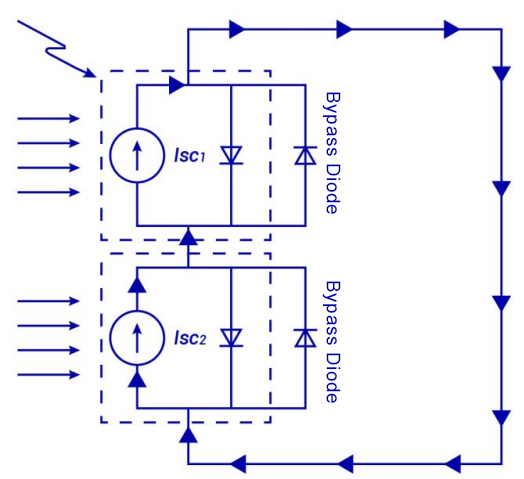

Working principle of bypass diode:

The diode is connected in parallel with the solar cell in the opposite direction. Under normal working conditions, the voltage of each cell is forward biased, so the voltage of the bypass diode is reverse biased, which is equivalent to an open circuit and has no effect. When one of the cells in the series is blocked or mismatched, the voltage is reverse biased. At this time, the bypass diode is equivalent to a wire and plays a shunt role. The photoelectric voltage generated by other normal series cells can still be used by the external load, thereby reducing the risk of hot spot effect to the entire photovoltaic module.

Working principle diagram of bypass diode to avoid hot spot heating effect

Therefore, the design and corresponding detection of a reliable bypass diode device are crucial for photovoltaic modules.

IEC61215 standard - MQT18 bypass diode test

MQT 18.1 bypass diode thermal performance test:

heat the photovoltaic module and junction box to 30℃, 50℃, 70℃, 90℃, apply a 1ms pulse current (Isc under STC conditions) to the bypass diode, test its forward voltage drop VD respectively, and draw a fitting curve VD-Tj; heat the module to 75℃, power on Isc under STC conditions for 1h, measure the VD of each bypass diode, increase the current to 1.25 times Isc, and maintain for 1h.

MQT 18.2 bypass diode function test:

pass forward current, test the diode forward voltage drop, and determine the performance; block the module battery, measure the I-V curve, and determine the performance.

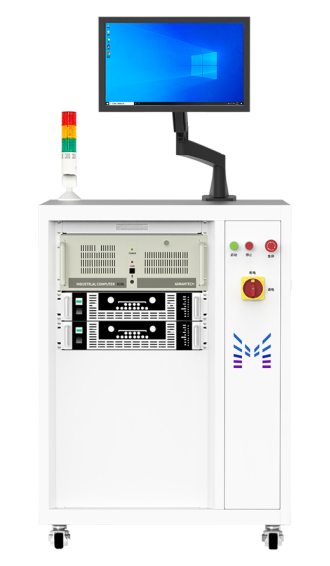

Bypass Diode Tester

E-mail: market@millennialsolar.com

Bypass Diode Tester ME-PV-BDT uses Advantech's high-quality industrial computer to ensure long-term stable operation of the equipment. The equipment has both thermal performance testing and thermal runaway testing systems, can apply pulse power, pulse width ≤1ms, and provide forward and reverse switching DC power. With environmental chamber, temperature control can be achieved.

● Pulse current adjustment range: 0A-50A, width ≤1ms

● Can collect pulse current, diode voltage drop, junction box temperature

● Accurate TJ value, automatic simulation of VD-Tj relationship

Although the hot spot effect of photovoltaic modules is a normal phenomenon, it should be avoided as much as possible, from the early production of battery cells to the inspection after the module manufacturing is completed, from all links to reduce the probability of affecting the occurrence of hot spot effect, and package the photovoltaic system to maintain good power output. With advanced and precise inspection equipment, Millennial Solar provides comprehensive testing services for IEC61215 and IEC61730 standards to help manufacturers improve the quality assurance of photovoltaic modules.