Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Solar Cells | Comparative Analysis of Three-Point and Four-Point Bending Tests

Date : 8 August 2024Views : 955

The fragility of silicon wafers has become a key factor restricting the performance, life extension and production efficiency of solar cells. In view of this, in the field of crystalline silicon photovoltaics, while pursuing high-efficiency output and cost optimization, the mechanical strength and toughness of crystalline silicon are regarded as an indispensable core consideration. Among them, three-point bending and four-point bending tests are particularly critical. Millennial Solar Solar Cell Comprehensive Tensile Tester, which has both horizontal 180° peel strength test and vertical cell bending test.

Quality and stability are the core considerations in the design and production of solar cells. To ensure that the product can operate stably and for a long time under complex and changing environmental conditions, a series of rigorous tests and verifications are indispensable, among which the three-point bending and four-point bending tests are particularly critical.

Bending test comparison

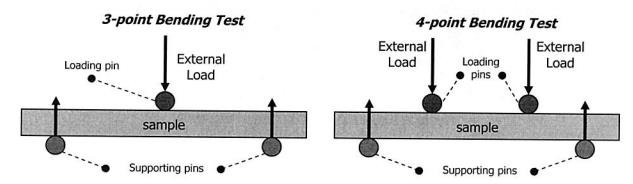

Depending on the specific needs, two different loading methods can be used: three-point bending or four-point bending. The three-point bending method applies a concentrated force on the sample to cause it to bend between two fixed support points. The four-point bending method adds a support point above the sample to form a more uniform stress distribution.

The stress conditions and parameters of the three-point bending and four-point bending test specimens are shown in the figure below. The load-displacement relationship curve is measured by the bending strength tester, and the fracture strength of the specimen is calculated.

Test diagram (left) three-point bending (right) four-point bending

Mechanical properties under bending test

The mechanical properties of two groups of samples were tested using three-point bending and four-point bending test methods: single-crystal silicon wafers and double-sided electrodes, and the curves of bending load and bending displacement.

(Left) Load and displacement curve of a monocrystalline silicon wafer (Right) Load and displacement curve of a bifacial cell

Black: three-point test; red: four-point test

For monocrystalline silicon wafers, the slope and extension of the curve of the bending load and bending displacement obtained by the four-point bending test method are higher than those of the three-point bending test method. Although the crushing load and maximum bending displacement obtained by the two test methods are not much different, both at 6.87 N and 34.76 mm, the maximum load of the monocrystalline silicon wafer obtained by the four-point bending test method is 11.55 N, which is higher than the maximum load of 6.87 N in the three-point bending test.

For bifacial cells, the maximum load and crushing load measured by the three-point bending test method are consistent, both 6.46 N, and the maximum bending displacement is 17.9 mm, while the maximum load measured by the four-point bending test method is 10.85 N, the crushing load is 10.24 N, and the maximum bending displacement is 22.24 mm. There is a large difference in the results measured by the two test methods.

Comparative analysis of bending tests

For single crystal silicon wafers, the four-point bending test shows obvious advantages over the three-point bending test. The maximum bending displacement dispersion under the four-point bending test is smaller, which means the measurement results are more stable and repeatable. At the same time, the maximum load that the silicon wafer can withstand in the four-point bending test is significantly increased, which directly reflects the enhanced relative load-bearing capacity of the silicon wafer under more uniform stress distribution.

For bifacial batteries, due to the presence of metal electrode grid lines, the dispersion of the maximum bending displacement measurement results under the two test methods is not much different, but the four-point bending test method also enhances the load-bearing capacity of the battery sheet. Therefore, the four-point bending test has more accurate results and higher repeatability than the three-point bending test method.

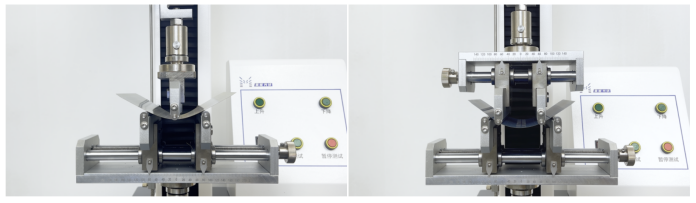

Solar Cell Comprehensive Tensile Tester

E-mail: market@millennialsolar.com

Solar Cell Comprehensive Tensile Tester ME-CELL-CTT is a special test equipment developed according to the photovoltaic industry, which is specially used for testing the peeling force, tensile strength and other related products of silicon wafers, silicon materials, PV modules and other related products in the photovoltaic industry. This equipment is a horizontal and vertical integrated cell tester that combines horizontal 180° peeling strength test and vertical cell bending test.

√ Horizontal test module can use up to 28 sensors at the same time

√ Vertical test module can be used for tensile compression, bending and other tests of finished batteries or materials

√ Complies with CB/T16491-2009, CB/T16491-96 and JB/T17797-95 national standards.

Three-point bending and four-point bending tests each have their own unique advantages and limitations. In practical applications, the appropriate test method should be selected according to specific needs and material properties. Millennial Soalr Solar Cell Comprehensive Tensile Tester can perform both bending tests and strip peel strength tests on cells to achieve the purpose of evaluating the mechanical properties of cells.