Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Effect of Poly Layer Thickness on the Electrical Performance of N-type TOPCon Cells

Date : 13 August 2024Views : 865

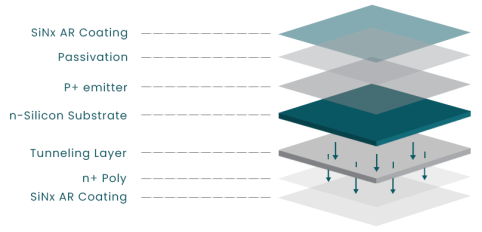

TOPCon solar cells with ultra-thin silicon oxide SiOx film and phosphorus-doped polysilicon Poly layer have a theoretical efficiency limit of up to 28.7%, becoming a hot research technology in the industry. TOPCon cells show superior passivation quality at the metal-silicon contact interface, with higher carrier selectivity and lower recombination rate. However, n+Poly layers of different thicknesses will affect the microstructure formed by the metallized contact, the passivation effect and the electrical performance of the cell. Millennial In-line Thin Film Thickness Tester is designed for photovoltaic process monitoring to help customers accurately obtain film thickness distribution information at different locations of the sample, monitor the stability of the process in real time, and thus optimize the film thickness.

Doped polysilicon is usually crystallized from an amorphous silicon layer a-Si after high temperature heat treatment. Typically, the preparation methods include PECVD, LPCVD, atmospheric pressure CVD, high pressure CVD, sputtering and electron beam evaporation. By studying the parameters of the passivation contact, such as the structural properties and thickness of the SiOx film and the Poly layer and the metallization of the passivation contact, it can provide valuable insights into the influence of the deposition preparation process parameters on the Poly layer and the cell performance.

Schematic diagram of TOPCon solar cell structure

By controlling the interface defects of the SiOx film and the doping concentration of the Poly layer, the doped Poly layer can obtain good passivation performance and low contact resistivity. The thickness of the Poly layer can be changed by controlling the deposition process method. Different thicknesses will affect the saturation current density, metallization composite and contact resistivity ρc of the emitter.

Below we measure and analyze polysilicon Poly layers with thicknesses of 30nm, 50nm, 70nm, and 100nm.

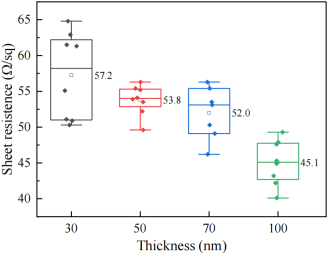

Sheet resistance R□

When the thickness of the n+Poly layer decreases from 100nm to 30nm, the sheet resistance (R□) of the cell increases from 45.1 to 57.2Ω/sq. This is because the thickness of the Poly layer determines the total doping amount. Although the surface doping concentration is the same, as the thickness continues to increase, the total doping amount also increases, resulting in a decrease in the sheet resistance of the cell.

Sheet resistance diagram of TOPCon solar cells with different n+Poly layer thickness

Contact resistivity ρc

When the thickness of the n+Poly layer increases from 30nm to 100nm, the contact resistivity decreases significantly. As the thickness increases, the total doping concentration also increases, thereby narrowing the width of the depletion region inside the silicon wafer and promoting the quantum tunneling effect of carriers through the Schottky barrier. A thicker Poly layer can provide more doping atoms and reduce contact resistivity.

Contact resistivity ρc diagram of TOPCon solar cells with different n+Poly layer thickness

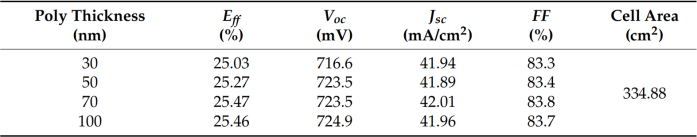

I-V parameters

The thinner n+Poly layer (30 nm) cannot provide sufficient doping concentration and passivation effect, resulting in lower efficiency Eff and open circuit voltage Voc. When the n+Poly layer thickness is 70 nm and 100 nm, the efficiency Eff, open circuit voltage Voc and fill factor FF of the solar cell are all optimal. This shows that these two thicknesses can provide good electrical performance and balanced doping concentration and resistance characteristics.

Table. I-V parameters of TOPCon solar cells with different n+Poly layer thicknesses

I-V parameters of TOPCon solar cells with different n+Poly layer thicknesses

From the above, it can be concluded that the thickness of the Poly layer has a significant impact on the electrical performance of TOPCon solar cells. Thicker Poly layers have lower sheet resistance and provide higher conductivity. This also shows that when designing and manufacturing solar cells, the thickness of the Poly layer needs to be optimized, which is critical to achieving high-efficiency TOPCon solar cells.

In-line Thin Film Thickness Tester

E-mail: market@millennialsolar.com

In-line Thin Film Thickness Tester can complete the precise detection of thin film thickness while connecting to the industrial detection process, so that battery manufacturers can use this equipment for large-scale systematic detection in the deposition process production line, thereby helping battery manufacturers to greatly save detection time, improve production efficiency and quality assurance!

· Poly film thickness test range 20nm-2000nm

· Fast, automatic 5-point synchronous scanning

· Non-contact, non-destructive measurement, zero fragmentation rate

· 24-hour automatic and non-stop calibration to ensure production efficiency

In practical applications, optimizing the thickness of the Poly layer can achieve a better balance between performance and cost, and achieve the overall efficiency and economy of n-TOPCon solar cells. In-line Thin Film Thickness Tester is designed specifically for photovoltaic process monitoring, helping customers to accurately obtain film thickness distribution information at different locations of the sample, monitor the stability of the process in real time, and thus optimize the film thickness.