Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Comparison of Modules Efficiency Before and After Dynamic Mechanical Load Testing

Date : 15 August 2024Views : 1510

The service life of photovoltaic modules in the field is expected to be at least 20 years. To ensure this, the mechanical integrity of photovoltaic modules is very important. One of the key factors affecting the efficiency of photovoltaic modules is the diversity of external climatic conditions in the environment where they are installed. Millennial Solar Dynamic Mechanical Load Tester tests photovoltaic module performance and impact by simulating different dynamic and static mechanical loads in the environment, which helps to improve the reliability and service life of photovoltaic modules.

The mechanical load test is to test the reliability of PV modules under uniform loads of 2400 Pa and 5400 Pa. According to the IEC-61215 standard, the load is applied to the surface of the PV module for 3 hours, and electroluminescence (EL) imaging and solar irradiation tests are performed before and after the load to characterize the performance and impact of the load on the PV.

Verification and testing

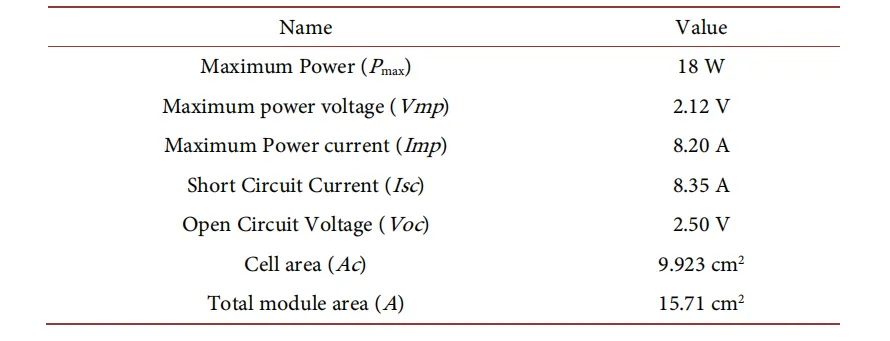

PV is differentiated and named according to the type of cells (monocrystalline and polycrystalline) and the number of busbars (3 and 4): monocrystalline 3 busbars (MT-3BB), monocrystalline 4 busbars (MT-4BB), polycrystalline 3 busbars (PT-3BB) and polycrystalline 4 busbars (PT-4BB). The important rated specifications of PV are shown in the table:

Pressure (about 5400 Pa) is applied to the front surface of PVs with different busbar numbers and cell types using a test device for 3 hours. According to IEC standards, this pressure is equivalent to the simulated mechanical load during the entire service life of the PV. In order to get the average effect of the load, 3 PVs of each model are tested according to the scheme shown in the figure below.

(a) Method for mechanical testing of photovoltaic modules (b) Circuit diagram of solar irradiation test design of photovoltaic modules

Monocrystalline and multicrystalline series PV with different numbers of busbars were tested to compare the mechanical integrity and electrical performance parameters of the PV, such as power, efficiency, fill factor, series resistance, etc., and the performance before and after the load was applied was compared. The important electrical performance parameters were determined by solar irradiation testing. The maximum power output before and after the load was applied was calculated using the following formula:

Where "I" is the maximum current output by the PV, and "V" is the maximum voltage generated during the solar irradiation test. Similarly, the efficiency of the PV is determined by the following formula:

Where "P" is the maximum power output of the PV at a given solar irradiance level "E". Where "A" is the total area of the module. Another important electrical parameter in the overall performance of PV is the fill factor. The fill factor is calculated by the following formula:

Here "Voc" is the open circuit voltage and "Isc" is the short circuit current determined by solar irradiation testing. The resistance provided to the flow of current is also an important parameter for PV reliability (PV series resistance) and is determined by the following formula:

Efficiency trend of PV before and after mechanical load

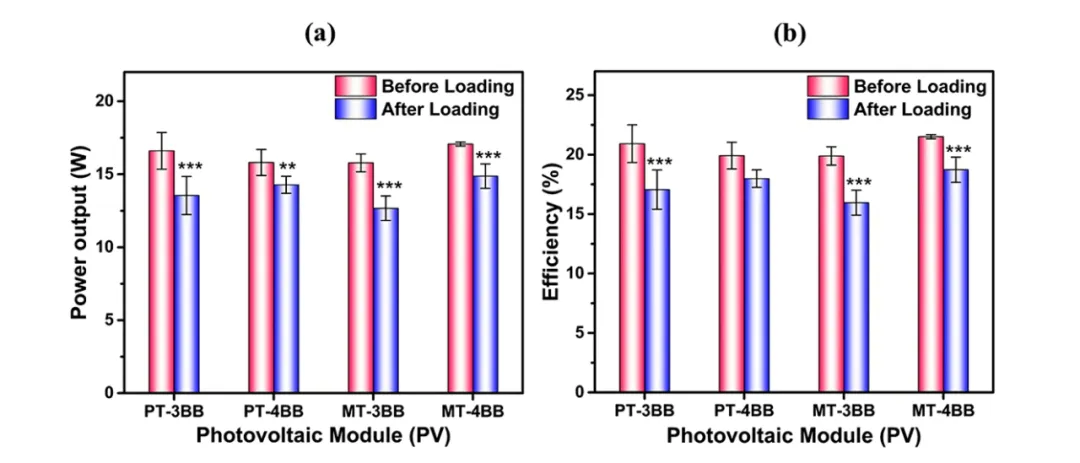

For all types of PV, the efficiency is still greater than 15%. The efficiency of the PT-4BB module is reduced by 9% at the minimum, while the efficiency of the MT-3BB module is reduced by 20% at the maximum.

Power and efficiency of different types of PV panels before and after load

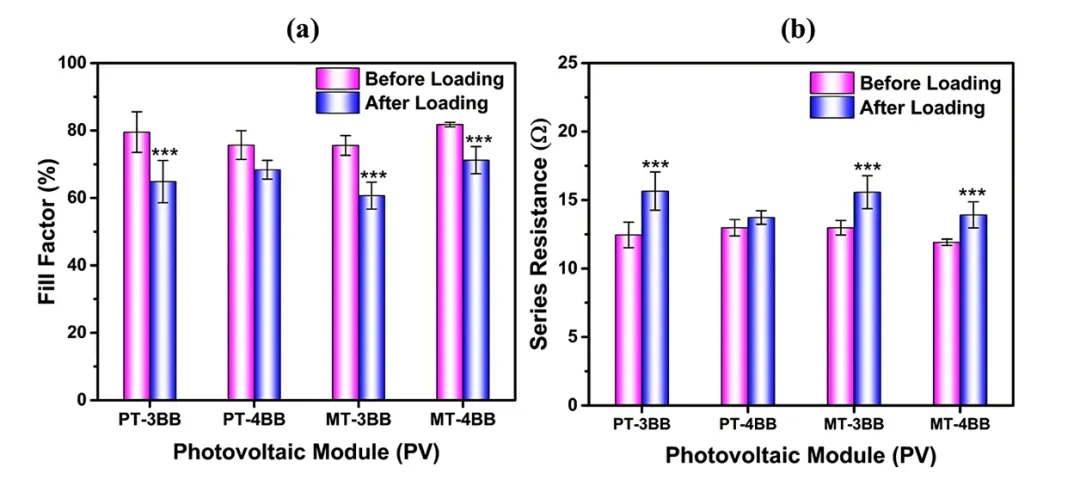

The overall performance, fill factor and series resistance of different types of PV are shown in the figure. MT-4BB has the highest fill factor of 82% ± 0.65%, and the fill factor after loading is 71% ± 4.03%. MT-3BB has the lowest fill factor, which is 60% ± 3.99% after loading.

(a) Fill factor (b) Series resistance of different types of PV modules before and after load

The power output and efficiency of a PV module is determined by a variety of parameters, including the amount of irradiation received, the reflectivity of the glass used, the manufacturing process used to manufacture it, and the mechanical integrity of the module. Mechanical load has a significant effect on the electrical properties of PT-3BB, MT-3BB and MT-4BB (p < 0.05). However, in the case of PT-4BB modules, the effect is less significant and the reason behind this is the different manufacturing process of solar cells.

In summary, the mechanical load simulation test step is introduced and optimized in the production process. Simulate various extreme environmental loads that the module may encounter, such as strong wind, snow, ice, etc., to ensure that the module's performance in actual applications can be fully verified during the design and production stages. It can not only improve the overall quality of the product, but also enhance the market competitiveness of the product and provide users with more reliable and durable solar photovoltaic modules.

Dynamic Mechanical Load Tester

E-mail: market@millennialsolar.com

Dynamic Mechanical Load Tester ME-PV-DML, 84-channel pressure sensor control, each cylinder is controlled separately; the suction cup spacing is adjustable, the universal structure ensures uniform force on the component surface, and the high-precision programmable DC power supply monitors the internal current continuity of the module.

·Load application method: The cylinder drives the suction cup;

·Up to 84 (12*7) cylinders can be installed, and each cylinder is controlled separately;

·The test system pressure, tension, holding time, cycle test, cycle frequency, and current size can be pre-set;

·The test system can record and store the positive pressure, reverse pressure, deformation, temperature, number of cycles, and current value during the test.

By simulating different mechanical loads in the environment, testing the performance and impact of photovoltaic modules helps to improve the reliability and service life of photovoltaic modules. Millennial Solar Dynamic Mechanical Load Tester has both static load and dynamic load testing functions, simulating the components to withstand alternating positive and negative pressure tests, accelerating module material fatigue, and testing the true reliability of the module.