Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

The measurement of square resistance monitors the process of preparing PN junction by doping

Date : 28 October 2024Views : 825

As the mainstream solar energy core conversion technology in the market today, the performance optimization of crystalline silicon solar cells depends on the precise design of the structure and the monitoring of the manufacturing process, among which the PN junction doping control is particularly critical. This aspect directly affects the photoelectric conversion efficiency and long-term stability of solar cells, and is an indispensable part of improving the overall performance.

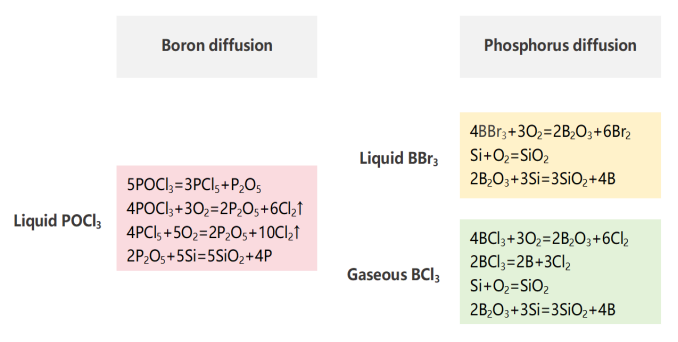

Crystalline silicon solar cell manufacturing uses high-temperature chemical thermal diffusion to achieve doping PN junctions. Boron diffusion and phosphorus diffusion are two different doping technologies. The choice depends on the design requirements. For example, phosphorus diffusion is used to form the emitter in the production of N-type silicon-based cells, and boron diffusion is used to form the emitter in the production of P-type silicon-based cells.

Doping rate and time are mainly used to control the depth and doping concentration of PN junction in solar cell manufacturing. The process control determines the separation efficiency and diffusion length of carriers inside the silicon wafer. Accurate control of the diffusion process is one of the keys to improving cell performance.

Doping time that is too short or too long will cause uneven distribution of dopants in the film, and the sheet resistance will vary in different areas. The sheet resistance value is mainly a comprehensive representation of surface concentration and junction depth. Its influence on the cell parameters mainly has the following three points:

1. The depth of the diffused PN junction directly affects its absorption of short-wave light. Therefore, within a certain range, the shallower the diffused PN junction (the higher the sheet resistance), the higher the current value;

2. The doping concentration of the diffused phosphorus element affects the conductivity of the N-type silicon part to a certain extent. Therefore, the higher the doping concentration (the smaller the sheet resistance), the higher the fill factor;

3. Within a certain range, the open circuit voltage will increase as the diffusion concentration increases.

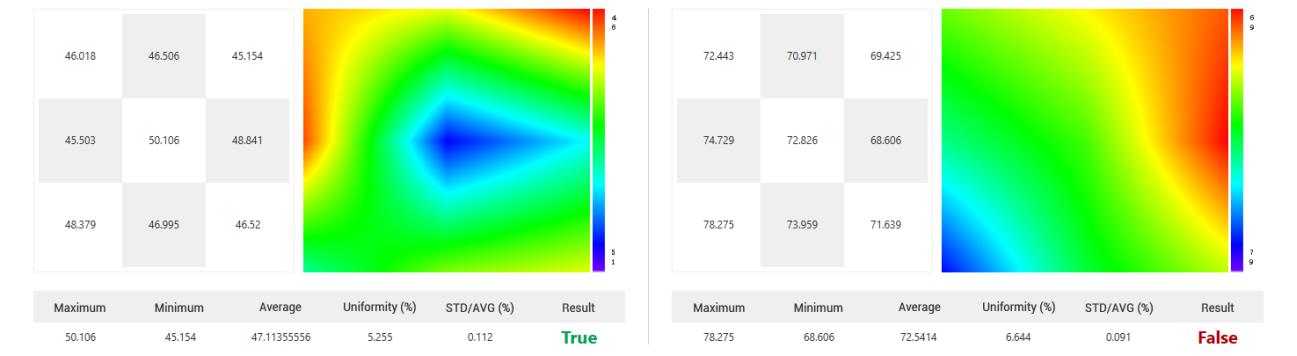

Millennial In-line Four Point Probe Tester test data and heat map comparison

By measuring the sheet resistance of silicon wafers, important information about the uniformity and concentration of silicon wafer doping can be obtained. The value of the sheet resistance directly affects the lateral distribution of current and the vertical collection effect, which is closely related to the overall performance of solar cells. Millennial In-line Four Point Probe Tester, designed for inline monitoring of photovoltaic process, can quickly and automatically scan samples up to 230mm to obtain sheet resistance/resistivity distribution information at different positions.

Millennial In-line Four Point Probe Tester FPP230 Auto

Contact us: market@millennialsolar.com

Millennial In-line Four Point Probe Tester FPP230 Auto can measure the sheet resistance and resistivity information of samples online at 5/9 points. Its accuracy is comparable to that of offline Four Point Probe Tester and it can be seamlessly connected to various automation equipment manufacturers. The equipment has received wide acclaim from many automation equipment manufacturers and customers in the Chinese market and Asia.

■ Maximum sample: 230mm×230mm

■ Measurement range: 1mΩ~100MΩ

■ Number of measurement points: Supports 5-point and 9-point measurement. Testing 5 points at the same time meets ≤5 seconds. Testing 9 points at the same time meets ≤10 seconds

■ Measurement accuracy: Ensure the measurement accuracy of the same model. The test error between different test instruments is within ±1%

High-temperature chemical thermal diffusion is used to dope the PN junction. Precise control of the doping process is critical to improving the performance of solar cells. The doping process can be monitored by measuring the square resistance information. Use the Millennial In-line Four Point Probe Tester FPP230 Auto for high-precision, fast, automatic scanning to monitor the stability of your production line process in real time.