Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Low Silver Screen Printed Metallization for Industrial Grade TOPCon Cells Achieves 80% Silver Reduction

Date : 9 July 2025Views : 1660

This paper presents a low silver content screen-printed metallization design that significantly reduces silver usage while maintaining high efficiency through the use of silver dots and a floating finger structure with low silver content in TOPCon solar cells. Experiments to characterize the interface quality through advanced diagnostics such as photoluminescence (PL) imaging have shown an 85% reduction in back-side silver usage, bringing the overall cell silver consumption down to 7 mg/W, with an efficiency loss of only 0.1-0.2%. With further optimization of the printing and sintering processes, efficiencies comparable to industry standard silver metallization designs are expected to be achieved. This study provides a viable solution for the sustainable and cost-effective fabrication of TOPCon solar cells.

Research Methodology

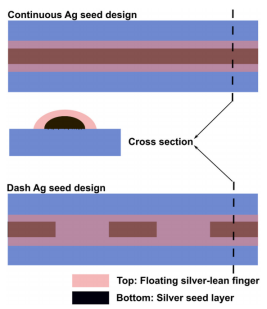

Schematic design of silver-saving metallization structure

Two-step printing process: First, a small amount of conventional silver paste is printed as a seed layer to create contact with the silicon surface. Then, floating finger lines and sink bars are printed, using alternating silver-sparing pastes. This two-step printing process ensures a high-quality metal/silicon interface while reducing the material compatibility requirements of silver-sparing pastes.

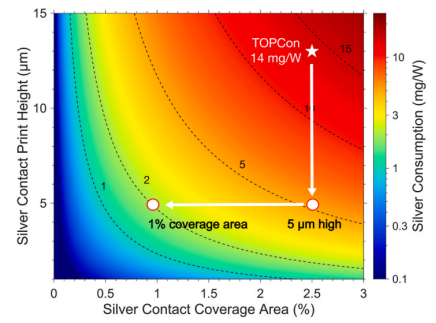

TOPCon Cell Silver Consumption - Contact Coverage as a Function of Print Height

Dot Matrix Seed Layer Configuration: The area covered by the silver contacts is further reduced by printing the silver paste as intermittent dots or dot contacts. This design allows the flexibility to optimize the process by adjusting the spacing between the dots.

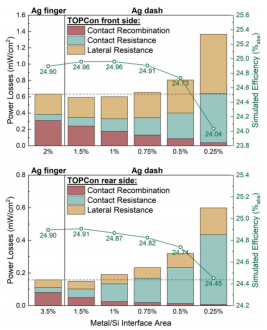

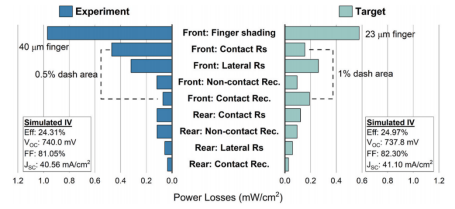

Simulation of cell efficiency and loss decomposition of TOPCon cells with standard silver finger wires and dot matrix structures

Numerical Simulation: Numerical simulations were performed using Quokka 3 to evaluate the potential impact of dot matrix design on cell performance. Simulation parameters are based on current industrial TOPCon cells and include wafer size, thickness, body resistivity, lifetime, number of busbars, finger width, finger spacing, contact resistivity, contact complexity, passivation surface, emitter sheet resistivity, and polysilicon doping density.

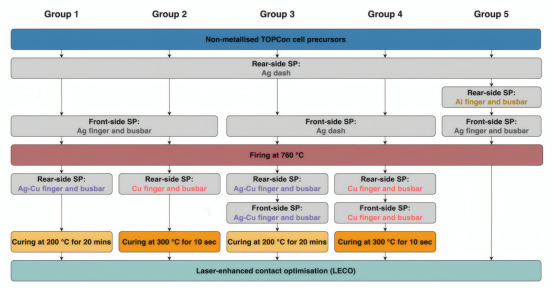

Experimental design

Process flow for preparation of silver-saving metallized TOPCon cells

Data collection: Non-metallized industrial TOPCon cell precursors were used, which were made from n-type industrial grade Cz wafers with a thickness of 130 μm and a body resistivity of 0.6-1.2 Ω cm.

Experimental procedure: the experiment was divided into five groups:

Groups 1 and 2: intermittent silver dots were printed on the rear surface of the TOPCon precursor, followed by conventional silver finger wires, busbars, and solder joints on the front, and an industry-standard sintering process was performed.

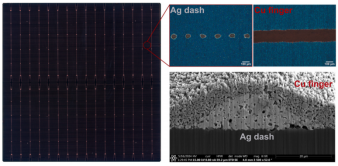

Surface topography characterization after silver-sparing metallization of TOPCon cells

Groups 3 and 4: Silver dots are printed on both the front and back surfaces, followed by the printing of silver clad copper or pure copper finger wires, busbars and solder joints.

Group 5: Only high-temperature pastes were used, omitting the low-temperature curing step, and all screen-printing steps were completed prior to the sintering process.

Sample selection: Preparation of a large area (182 x 182 mm²) TOPCon solar cell using two commercially available burn-through silver pastes for the front and back sides.

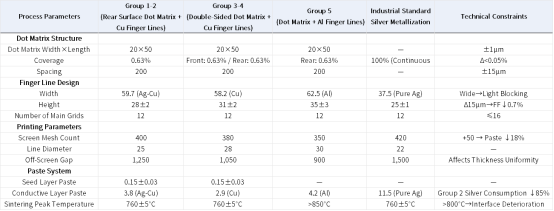

Parameter Configuration: The screen parameters and patterning are detailed in the table below, with a silver dot matrix of 14 μm width, 50 μm length and 0.43% area.

Silver-saving metallization TOPCon cell screen printing parameter design

Results and analysis

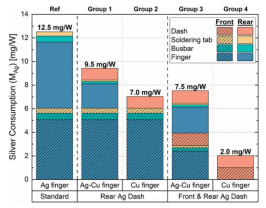

Comparison of Silver Consumption in TOPCon Cells (Multiple Metallization Schemes)

Simulation of efficiency loss and optimization path for double-sided silver-sparing metallization schemes

Silver-sparing metallization vs. low-temperature copper-based paste: The average efficiency of TOPCon cells using a silver-dot design on the rear surface is 24.95% using silver-coated copper finger wires and 25.05% using pure copper finger wires, which is a difference of 0.1-0.2% from the efficiency of standard silver finger wires. The loss of efficiency due to the silver-finger design is mainly due to a 0.5-1% decrease in fill factor (FF), which is mainly due to a decrease in metal/silicon interface area and an increase in contact resistance.

I-V Parameter Degradation of Rear Surface Aluminum Finger Line Scheme

Failure analysis of silver dot/aluminum finger line interface

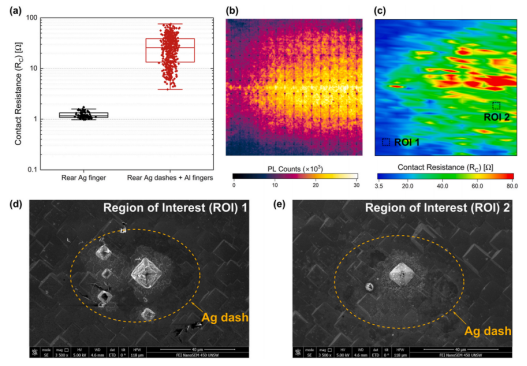

Aluminum-based scheme contact resistance with evidence of material degradation (a) contact resistance comparison (b) photoluminescence PL image (c) contact resistance distribution map (d) and (e) scanning electron microscope image of region 1/2

Silver-sparing metallization with high-temperature Al slurry: TOPCon cells using Ag dots and Al finger wires on both front and back sides showed a significant efficiency degradation, with VOC reduced by up to 25 mV and FF reduced by more than 10%, with an average efficiency of only 21.5%, suggesting a 3.5% efficiency drop. Through analytical means such as PL imaging, it was confirmed that aluminum diffusion triggered material degradation due to the undesirable interaction between Ag dots and Al finger wires during high-temperature sintering, resulting in damage to the metal/Si interface.

In this paper, a silver-saving metallization design based on existing industrial screen-printing techniques is proposed for significantly reducing silver consumption in TOPCon solar cells. By using silver dots and floating finger lines or sink bars on the front and back surfaces, an 85% reduction in silver consumption was achieved, with a total silver consumption of 7 mg/W.

Millennial PL/EL All-in-One Tester

E-mail: market@millennialsolar.com

Millennial PL/EL All-in-One Tester simulates sunlight irradiation on a chalcogenide solar cell wafer, uniformly illuminates the whole sample, and captures photoluminescence (PL) signals with a professional lens to obtain PL imaging; electroluminescence (EL) signals to obtain EL imaging. The captured PL/EL imaging is processed and analyzed by image algorithms and software, and PL/EL defects are identified, analyzed, classified, and summarized according to their characteristics.

EL/PL imaging with 5 megapixels for multiple imaging accuracy switching

Spectral response range: 400nm~1200nm

PL light source: blue light (light source size, wavelength, etc. can be customized)

Multiple defects identification analysis (pockmarking, darkening, edge intrusion, etc.) can be customized for defect types

Millennial PL/EL all-in-one tester in this article in photoluminescence (PL) analysis, through the blue light excitation to accurately capture the metallization interface defects. The high-resolution imaging capability and intelligent defect analysis features have become the cornerstone tool for interface failure diagnosis in TOPCon low-silver metallization studies.

Related Products