Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

A Review of Solar Cell Metallization Printing Technology: Screen Printing Optimization, Quality Control and Emerging Technologies Outlook

Date : 11 July 2025Views : 1425

This paper provides a comprehensive overview of metallization printing technologies for silicon solar cells, focusing on the evolution of screen printing, core challenges (e.g., fine line grids, optimization of silver paste consumption), the role of paste rheology, and quality control through the Millennial Screen Intelligent Tester, which ensures the accuracy of the printing process. Finally, we compare the potential of emerging technologies (e.g. stencil printing, parallel dispensing, rotary screen printing) to improve efficiency and reduce costs.

Evolution of Metallization Technology

Metallization, as a key part of silicon solar cell manufacturing, directly affects photoelectric conversion efficiency and production cost. Over the past 30 years, flatbed screen printing has occupied 98% of the global PV metallization market share with high throughput (>4000 wafers/hour), low scrap rate and a mature industrial supply chain. Its evolutionary history maps the process of PV industrialization:

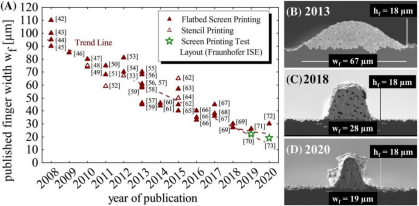

Screen-printed gate widths evolve, SEM maps show cross-section shape optimization

1975 Milestone: Spectrolab was the first to achieve mass production of screen-printed aluminum backfield (Al-BSF) cells, solving the p-type silicon contact problem;

2000s Breakthrough: Fire-through silver paste technology is compatible with phosphorus emitters and silicon nitride attenuator layer, driving the commercialization of PERC cells;

Current technology node: screen printing can achieve line width ≤20μm, supporting the PERC cell efficiency exceeds 23%.

With the rise of high-efficiency cells such as n-TOPCon, heterojunction (SHJ), and chalcogenide/silicon stacking, metallization is facing new challenges: ultra-fine grid lines (<30μm), low-temperature compatibility (<200℃), and silver paste depletion (now accounting for 15% of cell cost).

Metallization Technology Basics

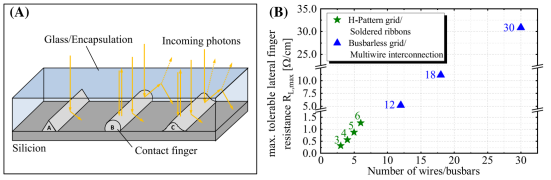

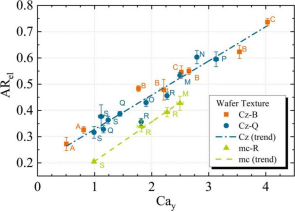

(a) Light reflection model with different grid cross sections (triangular/circular/Gaussian) in glass/EVA package (b) Maximum allowable lateral resistance RL,max with different number of interconnecting ribbons.

Electrode performance

Optical losses: grid line shading needs to be controlled within 5%, effective shading width wf,eff is determined by morphology (e.g. Gaussian cross section is 20% higher than circular shading);

Electrical losses: including contact resistance ρc, grid resistance Rgrid and metal-induced composite j0,met, j0,met in PERC cells up to 500-800 fA/cm²;

Material cost: silver paste consumption needs to be reduced to below 80 mg/cell (industry average around 85 mg in 2023).

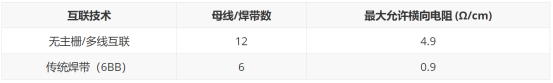

Interconnect Technology Innovations

Multi-barrier (MBB), Shingled and Busbarless designs significantly reduce sensitivity to barrier line resistance. When the gate line width is reduced to 30 μm, the allowable lateral resistance of the multi-master gate (12BB) solution reaches 4.9 Ω/cm, a 16-fold improvement over the traditional 3BB.

Screen Printing: Process Breakthroughs and Technical Bottlenecks

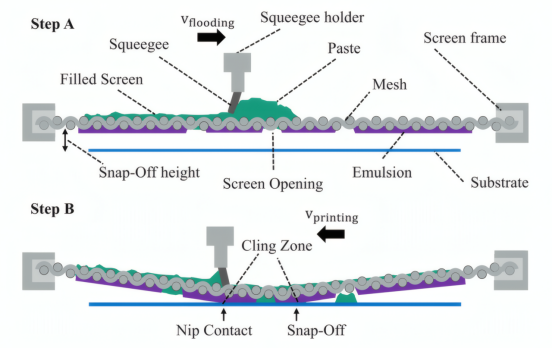

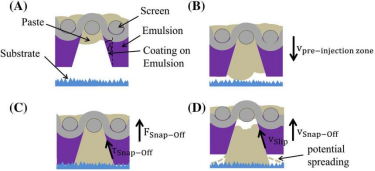

(A) Inking phase: squeegee movement fills the mesh (B) Printing phase: squeegee depresses the stencil into contact with the substrate.

The game of capacity versus precision

Modern production lines achieve higher aspect ratios through Double/Dual Printing:

Print-on-Print: Two prints are superimposed on the grid line, reducing the line width to 30 μm, but the register accuracy needs to be ≤ 12.5 μm;

Dual Print: Separate main grid/fine grid printing, with non-contact paste for the main grid to reduce composite loss j0,met by 25%.

Core process innovation

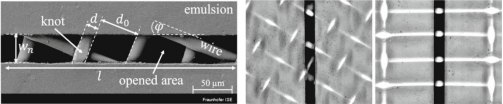

(A) Standard Mesh SEM Imaging (B) Conventional 22.5° Screen vs (C) Knotless Screen

Screen design: The Knotless Screen eliminates screen knots that hinder paste transfer and combines emulsion layer optimization (thickness ≤ 15μm) to achieve a line width of 19μm;

Mechanism of wall slip effect in the pop-off stage of stencil (A) Mesh filling state after inking (B) Squeegee pre-pressurized zone (C) Contact point shear stress (D) Wall slip velocity in the pop-off stage vslip

Rheology control: Wall Slip is controlled by the yield stress of the paste, reducing squeegee shear energy consumption by 30%;

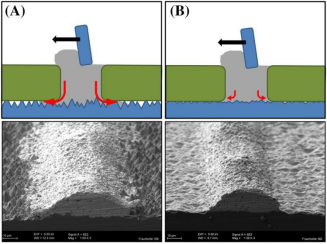

Influence of silicon velvet on printing edge sealing

Surface matching technology: Pyramid fleece texture height should be ≤3μm to ensure latex “gasket sealing” effect and inhibit paste overflow.

Key challenge: Screen life (>10,000 prints) and stability of 20μm line width mass production still need to be broken through.

Emerging Metallization Technologies

Rheology Control Laws of Dispensing Process

Parallel Dispensing:

Multi-nozzle synchronized dispensing for screenless printing, elimination of mesh marks, line widths up to 17 μm, and 20% reduction in silver consumption; 6-nozzle dispensing head with a capacity of up to 3,600 wafers/hour, compatible with low-temperature pastes for PERC/SHJ batteries.

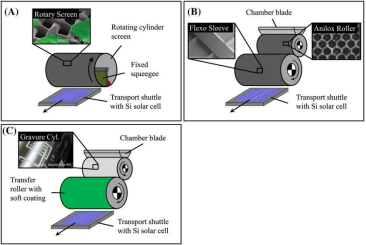

Principle of Rotary Screen Printing Technology

Rotary Printing:

Flexography: Laser-engraved EPDM printing plates, 5μm micro-cavity anilox rollers for controlled silver paste transfer, line width 30μm;

Rotary Screen: Continuous printing on cylindrical nickel mesh (400 mesh) with a theoretical capacity of >10,000 pieces/hour, suitable for backside full-side aluminum printing.

To address the limitations of screen printing in terms of ultra-fine line widths (<20μm) and high throughput, alternative technologies such as stencil printing, parallel dispensing (up to 17μm line width) and rotary screen printing (flexo/gravure) show potential for higher precision and lower silver consumption, but industrial maturity still needs to be improved.

Despite the emergence of new printing technologies, screen printing will still dominate TOPCon, HJT and other mainstream battery technologies due to its material system maturity, equipment ROI and process flexibility. Future breakthroughs are focused on: the development of high temperature / low temperature compatible multifunctional paste, build a digital twin system to realize the closed-loop control of the printing process, as well as to explore the silver-based paste to the smooth transition of the copper-based system.

Millennial Stencil Intelligent Tester

email:market@millennialsolar.com

Millennial Stencil tester AVT-4030 integrates four major inspection functions for detecting various characteristics of solar cell stencils including: size, defects, tension, and film thickness. Adopting 0.1μm scale, it realizes line width measurement accuracy of 0.3μm and PT value measurement accuracy of 2μm, which improves the quality of stencil.

Size, defect, film thickness, tension detection integrated

Screen plate inspection specification: ≤220*220mm (size can be customized)

High-resolution optical system, high precision, continuity, low cost, good flexibility

Millennial Screen Intelligent Tester plays a cornerstone role of process quality control in silicon solar cell metallization printing technology research, and its four core functions perfectly match the key process bottlenecks pointed out in the research (especially for the screen printing of ultra-fine line widths for mass production needs), and solves the process problems in the upgrade of solar cell metallization technology.

Original reference:Printing technologies for silicon solar cell metallization: A comprehensive review

Related Products