Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

TOPCon Cell Efficiency Improvement: Laser Oxidation Integrates TOPCon Front Surface Poly-Fingers Contacts

Date : 16 July 2025Views : 1255

Although double-sided TOPCon cells (DS-TOPCon) have a high open-circuit voltage (>728 mV), the full-area polysilicon poly-Si layer on the front surface leads to severe light parasitic absorption - >1 mA/cm² of current can be lost at 200 nm thickness. Conventional schemes to thin the poly-Si deteriorate the metallization contact, whereas a selective zone structure (where the poly-Si exists only under the metal gate line) can balance optical and electrical performance.

In this paper, we analyze an innovative process for the preparation of selected zone poly-fingers contacts on the front surface of TOPCon solar cells using nanosecond UV laser oxidation. In optimizing the process, we employed a Millennial 3D confocal microscope for high-precision 3D imaging of the surface morphology and defect analysis to support the development of the constituent structures.

Research Methods

Sample Preparation

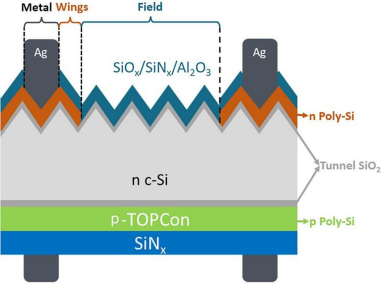

Schematic of a back-junction selective region bifacial TOPCon solar cell

Symmetric structure: n-poly-Si/SiO₂/n-Si/SiO₂/n-poly-Si, substrate 3 Ω-cm n-type CZ wafers (bifacial suede).

Tunneling oxide layer: 15 Å SiO₂ prepared in HNO₃ solution (100°C).

Polysilicon deposition: 200 nm n-type poly-Si grown by LPCVD (588°C).

Laser Patterning Process

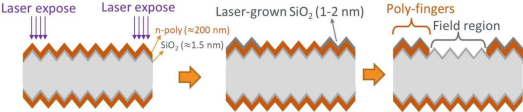

Schematic diagram of laser oxidation mask and polysilicon etching flow

This study proposes a three-stage innovative flow:

Laser oxidation: 355nm nanosecond laser (≥3W, 400mm/s) grows 1-4nm stoichiometric SiO₂ on the TOPCon surface;

Selective etching: KOH solution (9%/40°C) removes 200nm poly-Si in the mask-free region to form 100μm wide poly-Si-fingers;

Passivation Repair: PECVD deposition of 70 nm SiNₓ to compensate for laser damage and compatible with screen-printed metallization.

Results and Discussion

Optical Modeling

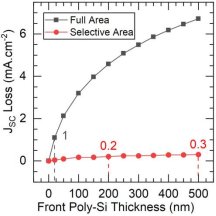

Simulation of photogenerated current loss for full-area vs. selective TOPCon

Effect of polysilicon thickness on current loss:

Full-area TOPCon: Jₛc loss >1 mA-cm-² at thickness >20 nm.

Selective TOPCon (100 μm wide finger zone): Jₛc loss only 0.2 mA-cm-² at 200 nm thick, insensitive to thickness variations (0.3 mA-cm-² loss at 500 nm).

Laser oxidation mechanism

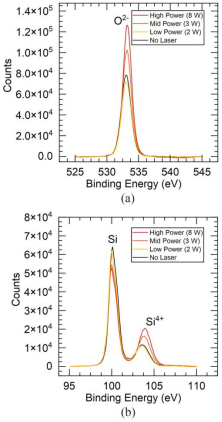

XPS profiles of (a) O²- peak and (b) Si⁴⁺ peak at different laser powers

Oxide layer characterization: XPS confirms the generation of dense SiO₂ with O²- enrichment (532 eV) and Si⁴⁺ peak offset (103.5 nm) at laser power ≥ 3 W, which is consistent with the Deal-Grove thermal oxidation model;

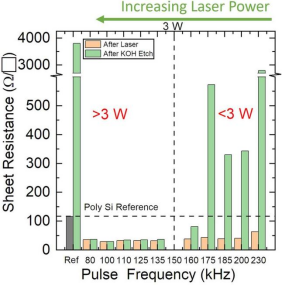

Measurements of cube resistance of poly-Si films before and after KOH etching

Etching selectivity: after 3W laser, the poly-Si square resistance stays ~30 Ω/□, indicating that the SiO₂ mask resists KOH etching for 90 seconds; below 3W, the mask fails.

Damage repair and passivation recovery

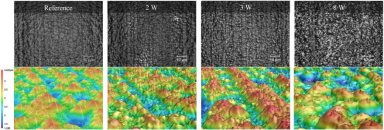

Laser confocal microscopy images (top view vs. isometric view)

Laser damage: power >3W leads to pyramidal weave rounding and J₀ spike ≤2300 fA/cm²;

Hydrogen passivation repair: after 70 nm PECVD SiNₓ deposition, J₀ at 3W laser drops to 43.2 fA/cm² (of which the laser surface contributes 36.8 fA/ cm²), and the selected poly-Si-fingers area composite is only 1.65 fA/cm² (4.48% coverage).

Cell simulation (Quokka 2)

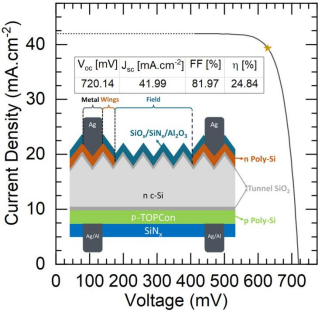

Simulated current-voltage characteristic curves of selective front surface bifacial TOPCon solar cells

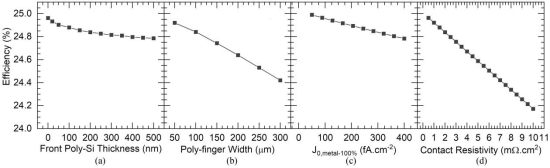

Simulated solar cell efficiency as a function of (a) polysilicon finger thickness, (b) finger width, (c) metal contact J0, (d) contact resistivity

Baseline efficiency: 24.84% (J₀,metal=300 fA-cm-², contact resistivity 2 mΩ-cm²).

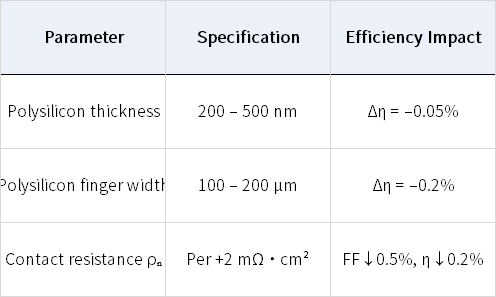

Sensitivity analysis of key parameters:

Thickness of polysilicon (200→500 nm): efficiency reduced by 0.05%.

Finger width (100→200 μm): efficiency reduced by 0.2% (Vₒc↓2.1 mV, Jₛc↓0.4 mA-cm-².

Metal contact J₀ (300→50 fA-cm-²): efficiency increased to 25%.

Contact resistance (per 2 mΩ-cm-² increase): ↓0.5% FF and ↓0.2% efficiency.

Industrialization path validated by Quokka2 cell simulation:

Process compatibility:

Fully compatible with screen printing production line (including 760°C sintering)

Eliminates 5 processes of traditional photolithography/TMAH etching, cost reduction ≥18%

Efficiency boundary:

Efficiency up to 25.0% (initial value 24.84%) at J0,metal ≤ 50 fA/cm²

In this paper, we analyze an innovative process for the preparation of front surface-selected polycrystalline silicon (poly-Si) contacts for TOPCon solar cells using nanosecond UV laser oxidation. The process realizes retaining only the poly-Si contact strip below the metal grid line by laser-induced growth of SiO₂ mask combined with KOH selective etching, which effectively solves the problem of light parasitic absorption of the full-area poly-Si layer on the front surface in conventional bifacial TOPCon cells. Experiments show that this solution significantly improves optical transmittance while maintaining excellent passivation performance, providing a new path for 25%+ efficient batteries.

Millennial 3D Confocal Microscope

email:market@millennialsolar.com

Millennial 3D confocal microscope ME-PT3000 is an optical instrument specialized in the photovoltaic industry for quality inspection of grid lines and velvet on the surface of photovoltaic substrates. The depth and width of the grid lines on the PV substrate and the number of pyramids on the velvet surface are quantitatively inspected to provide feedback on the process quality of the PV substrate.

Accurate and reliable 3D measurement for real-time confocal microscopy images

Ultra-high confocal lens with Z-axis display resolution up to 1nm

High precision and repeatability

Fully automated raster velvet measurement for fast data generation

Millennial 3D confocal microscopes are used throughout the process for sub-micron inspection of surface gratings and velvet, ensuring controlled optimization of optical performance.

Related Products