Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Improving TOPCon Cell Stability | Enhancing PL/EL Detection Compatibility with LECO-Compatible Silver Paste

Date : 15 August 2025Views : 2435

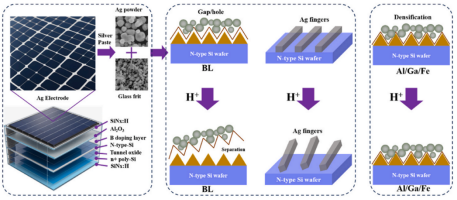

Laser-Enhanced Contact Optimization (LECO) is an effective technology for enhancing the efficiency of TOPCon cells. However, there is an urgent need to improve LECO-compatible silver paste to ensure the reliability and stability of TOPCon cells. This study optimized the glass-forming process by introducing Al/Ga/Fe elements into the inorganic glass powder of conductive silver paste. Using PL/EL imaging technology, the degradation behavior of TOPCon cells under standard acetic acid conditions was evaluated.

Schematic diagram of TOPCon cell structure and metallization degradation mechanism

Design and verification of corrosion-resistant glass materials

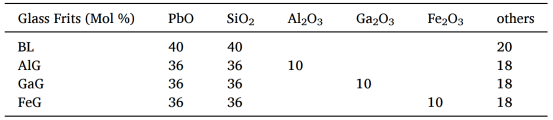

In this study, three modified glass materials were designed: AlG (with Al₂O₃ added), GaG (Ga₂O₃), and FeG (Fe₂O₃), with their molar compositions shown in the table below.

Table 1: Molar percentage composition of glass materials in the control group and experimental group

Using commercial TOPCon cells (N-type CZ silicon wafers, thickness 100 μm) as the substrate, the front electrode was printed with silver paste containing 88 wt% silver powder, 3 wt% glass powder, and 9 wt% organic binder. After sintering in a conveyor furnace, LECO treatment was performed (1064 nm laser, 45 W, 15 V bias).

Stability was evaluated via an acetic acid accelerated aging test (6g glacial acetic acid + 125g KCl + 200mL water, 80°C/8h). Key findings are as follows:

Table 2: Efficiency degradation rate of TOPCon cells after acetic acid treatment

The efficiency decay of silver pastes containing Al/Ga/Fe is less than 10%, with FeG at only 5%.

The unmodified BL group has a decay of up to 54%.

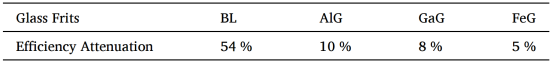

PL and EL imaging

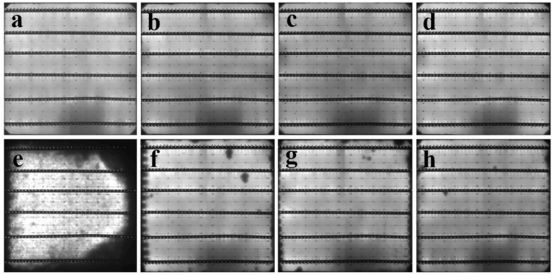

(a–d) PL images of TOPCon cells with LECO silver paste containing BL, AlG, GaG, and FeG before acetic acid treatment; (e–h) PL images of the corresponding samples after acetic acid treatment

The photoluminescence (PL) results show that there are no obvious abnormalities on the surface of the cells using AlG, GaG, and FeG silver paste before and after acetic acid treatment, indicating that these silver pastes do not cause significant damage or corrosion to the cells.

(a–d) EL images of TOPCon cells before acetic acid treatment using LECO silver paste doped with BL, AlG, GaG, and FeG; (e–h) EL images of the corresponding samples after acetic acid treatment

Electroluminescence (EL) characterization revealed: In the BL group, large-area black spots appeared after acetic acid treatment, indicating failure of grid line electrode contact; whereas in the AlG/GaG/FeG groups, only minor blackening occurred at the edges.

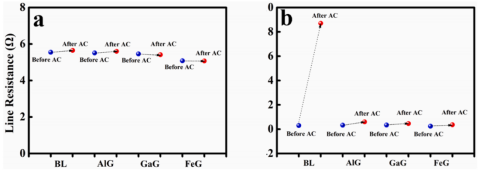

Contact resistance and line resistance

(a) Comparison of grid line resistance before and after acetic acid treatment; (b) Changes in contact resistance (significant increase in the BL group)

The contact resistance test results show that there was no significant change in line resistance before and after treatment for all test samples (including the control group), indicating that the silver grid electrodes did not suffer significant structural damage or corrosion during the treatment process. Combined with the PL characterization results, it can be inferred that the main cause of efficiency loss is the contact issue between the silicon wafer and the silver electrode.

This study optimized glass formation by introducing aluminum (Al), gallium (Ga), and iron (Fe) elements into the inorganic glass component of conductive silver paste, and evaluated the degradation behavior of TOPCon cells under standard acetic acid conditions. The results show that the silver paste containing Al/Ga/Fe exhibits significantly superior resistance to acetic acid corrosion compared to the untreated group, with efficiency loss controlled below 10% (as low as 5%), while the control group experienced over 50% loss. This study provides a high-reliability LECO-compatible silver paste solution for TOPCon solar cells.

Millennial PL/EL Integrated Testing Instrument

email:market@millennialsolar.com

The Millennial PL/EL Integrated Testing Instrument simulates sunlight exposure on perovskite solar cells, uniformly illuminating the entire sample. It uses specialized lenses to capture photoluminescence (PL) signals, generating PL imaging, and electroluminescence (EL) signals, generating EL imaging. Through image algorithms and software, the captured PL/EL images are processed and analyzed to identify PL/EL defects, which are then analyzed, classified, and summarized based on their characteristics.

EL/PL imaging, 5 million pixels, enabling multiple imaging resolution switching

Spectral response range: 400 nm to 1200 nm

PL light source: Blue light (customizable light source size, wavelength, etc.)

Multiple defect identification and analysis (pitting, darkening, edge intrusion, etc.) with customizable defect types

The Millennial PL/EL integrated tester can perform PL/EL imaging before and after acetic acid aging to “non-destructively, quickly, and visually” verify the acid corrosion resistance of Al/Ga/Fe glass materials and identify the efficiency degradation mechanisms of TOPCon cells.

Related Products