Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

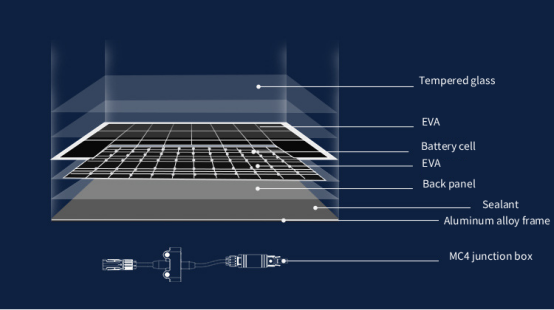

Basic Structure of Photovoltaic Modules

Date : 26 August 2025Views : 930

Photovoltaic modules are the core power-generating units that directly convert solar energy into electricity. Their structure employs a precise “sandwich” design, achieved by laminating and encapsulating multiple functional materials. This design aims to protect the solar cells from harsh outdoor environments (such as sunlight, rain, wind, sand, and extreme temperature fluctuations), ensuring they maintain stable and efficient power generation performance over the long term (typically exceeding 25 years).

The following are the main structural layers of a photovoltaic module (using a double-glass module as an example, from the light-receiving side to the back side):

1: Panel - Glass

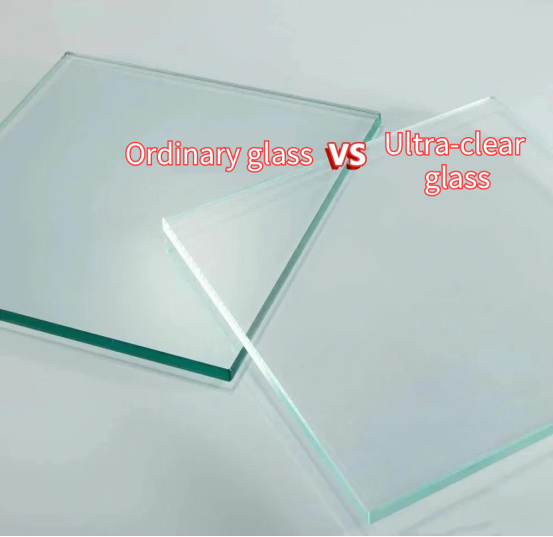

Function: As the outermost protective structure, its primary function is to prevent the internal solar cells from mechanical impact (such as hail), wind and sand abrasion, and rain erosion, while also possessing sufficient mechanical strength to withstand external loads such as snow accumulation. Additionally, this layer of material must have extremely high light transmittance (typically greater than 91.5%) to ensure maximum sunlight penetration to the surface of the solar cells, thereby ensuring optimal power generation efficiency.

Material: Low-iron ultra-clear tempered glass (common thicknesses are 3.2mm or 2.0mm). The low-iron content significantly reduces iron impurity absorption of light, enhancing light transmittance; tempering treatment enhances the glass's mechanical strength and safety—when broken, it shatters into small, blunt-edged particles, greatly reducing the risk of potential injury.

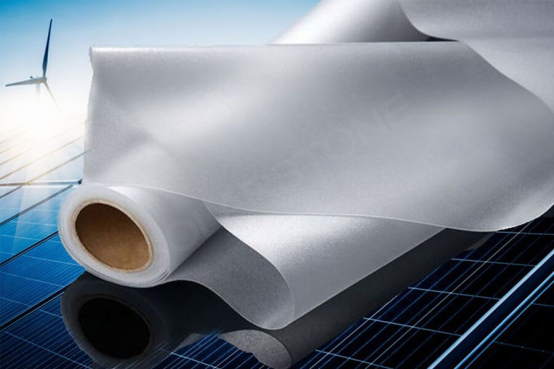

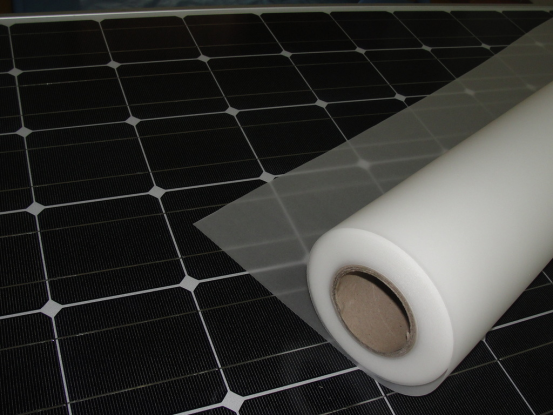

2: Upper Encapsulation Film

Function: Used to bond tempered glass to solar cells, it serves multiple purposes including light transmission, insulation, cushioning mechanical stress, and blocking moisture and oxygen. This effectively prevents environmental corrosion of the solar cells and extends the lifespan of the module.

Material: The most common material is ethylene-vinyl acetate copolymer (EVA film). Other materials such as POE and PVB are also used. During lamination, EVA melts and flows under heat, filling gaps, and then cross-links and cures to form a stable encapsulation structure. Modules typically have two layers of EVA, one on top and one on the bottom.

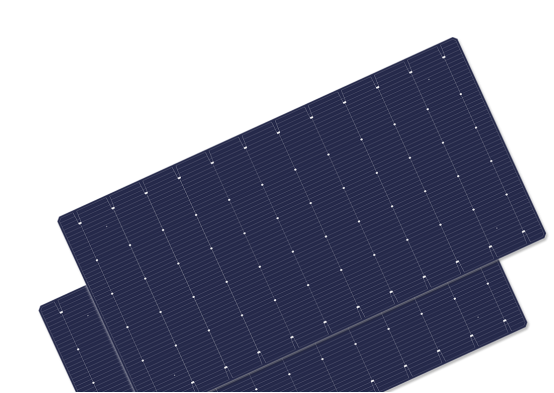

3: Core Power Generation Unit - Solar Cells

Function: The core of photovoltaic module power generation, utilizing the “photovoltaic effect” to directly convert solar energy into direct current electricity.

Materials and Structure: Typically silicon-based cells (monocrystalline silicon or polycrystalline silicon, with N-type monocrystalline silicon cells being the primary type currently), as well as thin-film cells (such as cadmium telluride CdTe, copper indium gallium selenide CIGS, and amorphous silicon a-Si). Monocrystalline cells typically have a thickness of approximately 130–150 micrometers.

Arrangement and Connection: Solar cells are connected in series using tin-coated copper strips (solder strips) to increase the output voltage, forming a battery string; multiple battery strings are then connected in parallel to increase the output current. The surface of the solar cells is coated with an anti-reflective layer (commonly a blue silicon nitride film) to enhance light absorption, and printed with fine metal electrodes (silver grid lines on the front and silver electrodes on the back) for current collection. Common solar cell arrangements include 60 cells (120 half-cells), 72 cells (144 half-cells), 54 cells (108 half-cells), and 78 cells (156 half-cells), among others.

4. Lower encapsulation film

Function: Similar to the upper encapsulation film, it bonds the solar cell to the backsheet, providing encapsulation protection, insulation, cushioning, and isolation.

Material: Mainly EVA film (or POE, etc.).

5: Backplate - Back Glass

Function: The protective layer on the back of the module. Its primary functions include providing electrical insulation, blocking moisture and oxygen (moisture-proof and oxidation-proof), protecting the solar cells from mechanical damage and environmental corrosion (such as UV rays and chemicals), and providing structural support.

Materials and Structure: Includes 2.0mm/1.6mm ultra-clear rolled glass and 2.0mm ultra-clear float glass, among others. A layer of approximately 20 microns thick white enamel is applied to the glass surface, which is then sintered to form the final product. The grid-patterned enamel reflects a portion of the light incident between the solar cells and strings back onto the cells, reducing light loss and enhancing module power output.

6: Frame

Function: Usually an aluminum profile frame surrounding the component. Its main function is to provide solid mechanical support and protection for the laminated parts, facilitate the installation, fixing, and transportation of the components, and provide grounding connection points.

Material: Anodized aluminum alloy. It is characterized by high strength, light weight, and corrosion resistance. Some specially designed components (such as lightweight components) may not have a frame.

7: Junction Box

Lead wires: Typically two cables with connectors, one positive and one negative, used to carry the DC electricity generated by the module to other modules or systems.

Bypass diodes: Key electronic components installed inside the junction box. When some of the cells in the module are shaded (e.g., by leaves, bird droppings, or shadows) or damaged, these cells become power-consuming units (hot spots) instead of power-generating units, obstructing the flow of current. The bypass diode conducts at this point, allowing current to bypass the shaded/damaged cell string, ensuring the entire module can continue to output most of its power and preventing the cells from being permanently damaged due to overheating (hot spot effect).

Function: The electrical output hub and protective device of the module.

Materials: Engineering plastic housing (e.g., PPO, PC), with conductive copper components and diodes inside.

8: Sealant & Encapsulant

Function: Sealant is used to fill the gaps between the junction box and the backplate, as well as between the frame and the edges of the laminated components (for framed assemblies), ensuring the assembly has excellent waterproofing, dustproofing, and sealing performance; encapsulant is used in three-piece junction boxes to provide waterproofing, moisture resistance, dustproofing, insulation, thermal conductivity, confidentiality, corrosion resistance, temperature resistance, and vibration resistance after curing.

Materials: Silicone sealant (silicone rubber) is the most commonly used due to its excellent weather resistance, elasticity, adhesion, and insulation properties; two-component thermal conductive potting compound offers superior temperature resistance, thermal conductivity, and insulation properties, making it a common choice for photovoltaic module potting compounds.

Note: The illustrations in this article are sourced from the internet.